CuO-loaded SiO2 catalyst applied to preparation of benzenediol and benzoquinone and preparation method of catalyst

A p-benzoquinone and catalyst technology, applied in the field of CuO/SiO2 catalyst preparation, can solve the problems of low conversion rate of raw materials, many side reactions, expensive raw materials, etc., and achieve high catalytic activity, simple preparation method, and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

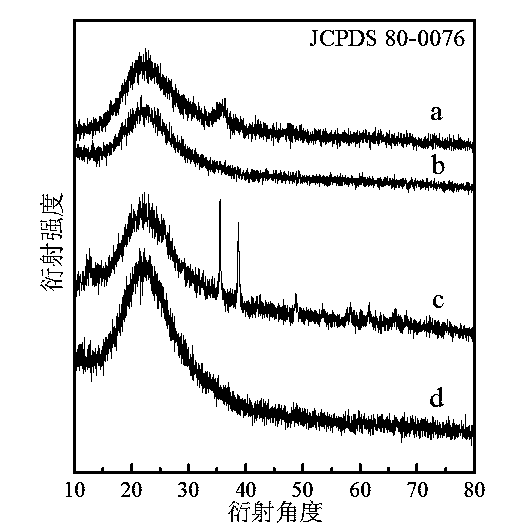

Image

Examples

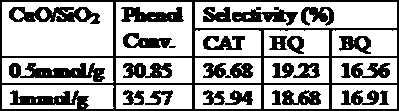

Embodiment 1

[0032] Take by weighing about 0.524g copper acetylacetonate (Cu(acac) 2 ) placed in the sublimator of the chemical vapor deposition device, take 2.0g nano-sized SiO 2 The particles are placed in the fluidized bed reactor, the chemical vapor deposition device is turned on, the vacuum degree is adjusted to 0.08MPa, and N 2 The carrier gas is 80mL / min, the temperature of the fluidized bed reactor is adjusted to 200°C, and the SiO 2 After the particles are dried for 2 hours, feed air into the sublimator at a flow rate of 80-100 standard ml / min, adjust the temperature of the sublimator to 190°C, and readjust the fluidized bed reactor to 260°C. ) 2 After complete sublimation, the temperature of the fluidized bed reactor was maintained for 2 hours, and the vapor deposition device was closed, so that the CuO / SiO 2 (1 mmol / g) catalyst preparation is complete.

Embodiment 2

[0036] Weigh about 0.263g of copper acetylacetonate (Cu(acac) 2 ) placed in the sublimator of the chemical vapor deposition device, take 2.0g nano-sized SiO 2 The particles were placed in the fluidized bed reactor, the chemical vapor deposition device was turned on, the vacuum degree was adjusted to 0.08MPa, and N 2 The carrier gas is 80mL / min, the temperature of the fluidized bed reactor is adjusted to 200°C, and the SiO 2 After the particles are dried for 2 hours, feed air into the sublimator at a flow rate of 80-100 standard ml / min, adjust the temperature of the sublimator to 190°C, and readjust the fluidized bed reactor to 300°C. ) 2 After complete sublimation, the temperature of the fluidized bed reactor was maintained for 2 hours, and the vapor deposition device was closed, so that the CuO / SiO 2 (0.5mmol / g) catalyst preparation is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com