Adaptive Tracking Elastic Sensor for Welding Groove

An adaptive tracking, elastic sensor technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low tracking dimension, difficult force system balance adjustment, large system error, etc., to achieve anti-interference ability and reliability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

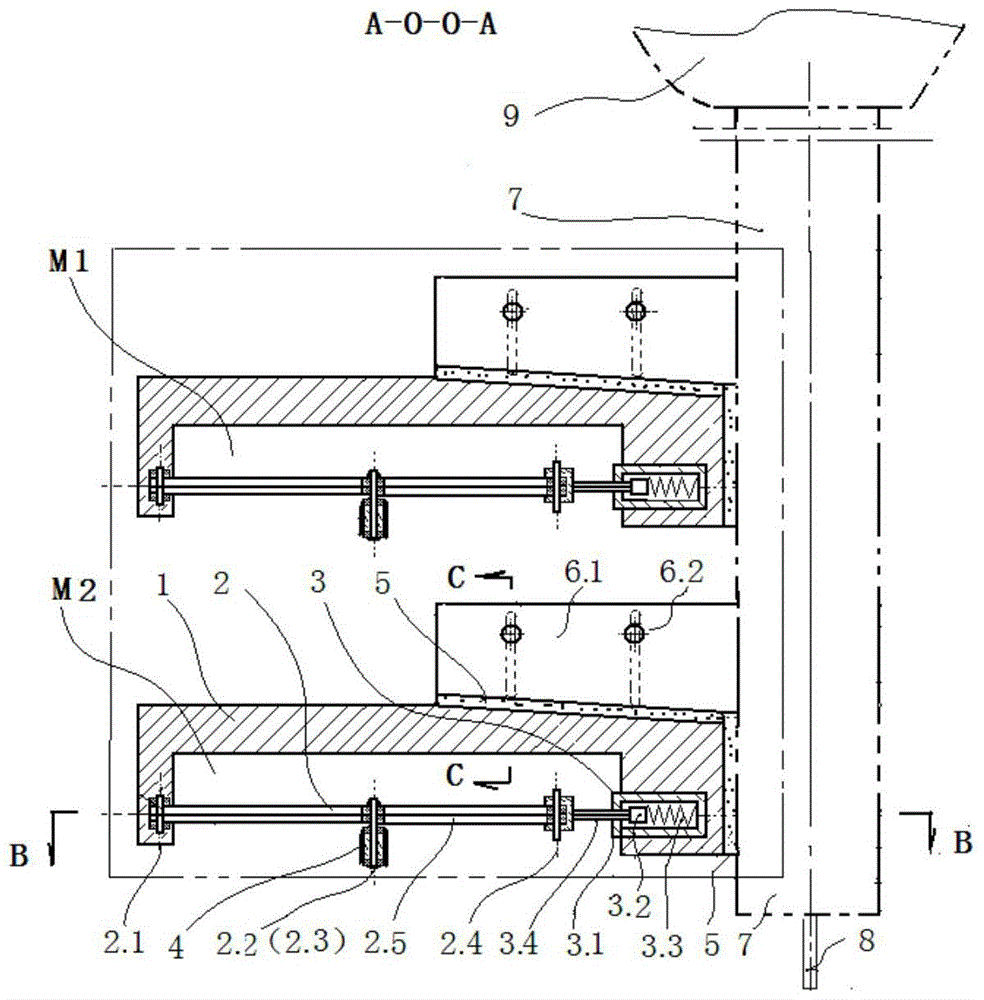

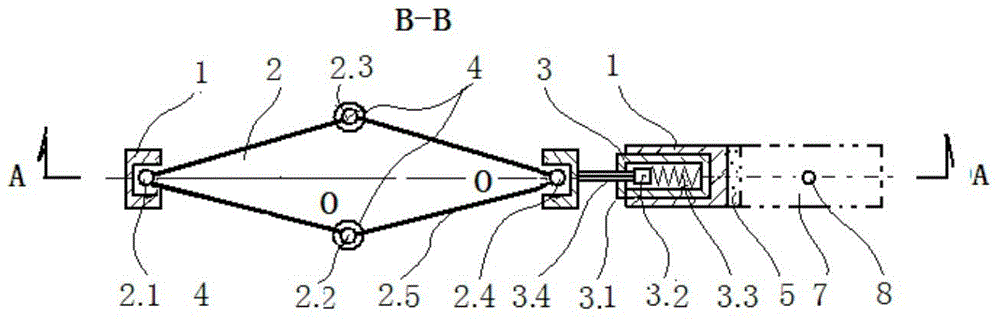

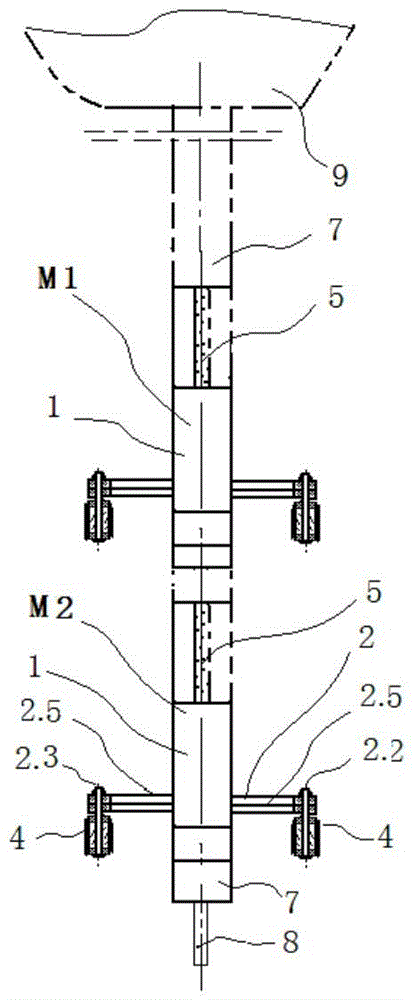

[0048] Example 1: is a basic example. Such as figure 1 , 2 , 3, 4, and 5 show an adaptive tracking elastic sensor for welding grooves, which is composed of an upper tracking seat M1 and a lower tracking seat M2; each of the two tracking seats includes an "n"-shaped tracking Base body 1, a four-hinge linkage mechanism 2, a piston assembly 3, and two detection rollers 4; the tracking base body 1 is detachably fixedly connected to the welding torch 7; the four-hinge linkage mechanism 2 includes a connecting Rod 2.5, static hinge shaft 2.1, opposite to the static hinge shaft 2.1 is the dynamic hinge shaft 2.4, and the other two opposite hinge shafts are also the shafts of the detection roller 4 on the side of the welding groove, which are respectively the detection hinge shafts on the first side 2.2 and the second side detection hinge shaft 2.3; the piston assembly 3 includes a piston cylinder 3.1, a piston 3.2, a piston rod 3.4, and a spring 3.3 in the piston cylinder; the p...

Embodiment 2

[0049] Example 2: is a further example. Such as figure 1 —5, and Figure 7 As shown in -12, the self-adaptive tracking elastic sensor for welding grooves, the static hinge axis, the dynamic hinge axis, the first side detection hinge axis, and the second tracking base M1 of the upper tracking base M1 and the lower tracking base M2 The hinge shafts are detected on both sides, and a total of 8 axis lines are parallel to and perpendicular to the axis line of the piston rod respectively. The tracking base bodies 1 of the upper tracking base M1 and the lower tracking base M2 are two independent components, or are connected integral components, or integral components formed at one time; the preferred tracking base M1 and the present embodiment The tracking seat body 1 of the lower tracking seat M2 is two independent components. Its advantage is that the distance between the upper and lower two tracking seats can be adjusted according to the depth of the welding groove, that is, ...

Embodiment 3

[0052] Example 3: Such as Figure 5 As shown, there is an automatic welding system with two sets of self-adaptive tracking elastic sensors for welding grooves of the present invention, which includes a welding trolley 9 with universal wheels 11 and a shock absorber 12; the welding torch of the welding trolley 9 7. A set of self-adaptive tracking elastic sensors are respectively installed symmetrically according to the forward and backward directions of welding: the first set is composed of the upper tracking seat M1 and the lower tracking seat M2, and the second set is composed of the second upper tracking seat M1' and the second The lower tracking seat M2' consists of the sensor center plane of the two sets of adaptive tracking elastic sensors being the same plane, which is parallel or coincident with the plane on the tracking seat body 1 used to connect the welding torch holder 6.1.

[0053] The front and back of the welding torch 7 each have a set, that is, the self-adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com