Bamboo bowl manufacturing technology and product thereof

A production process and technology for bamboo bowls, which are applied in the direction of manufacturing tools, wood processing utensils, plates, etc., can solve the problems of low utilization rate of plates, and achieve the effects of high utilization rate of bamboo materials, saving resources and simple processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

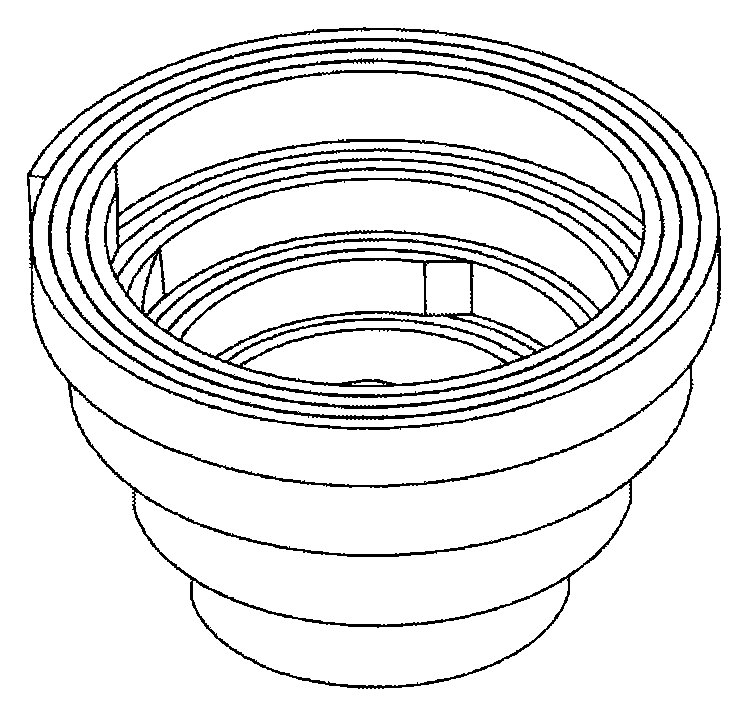

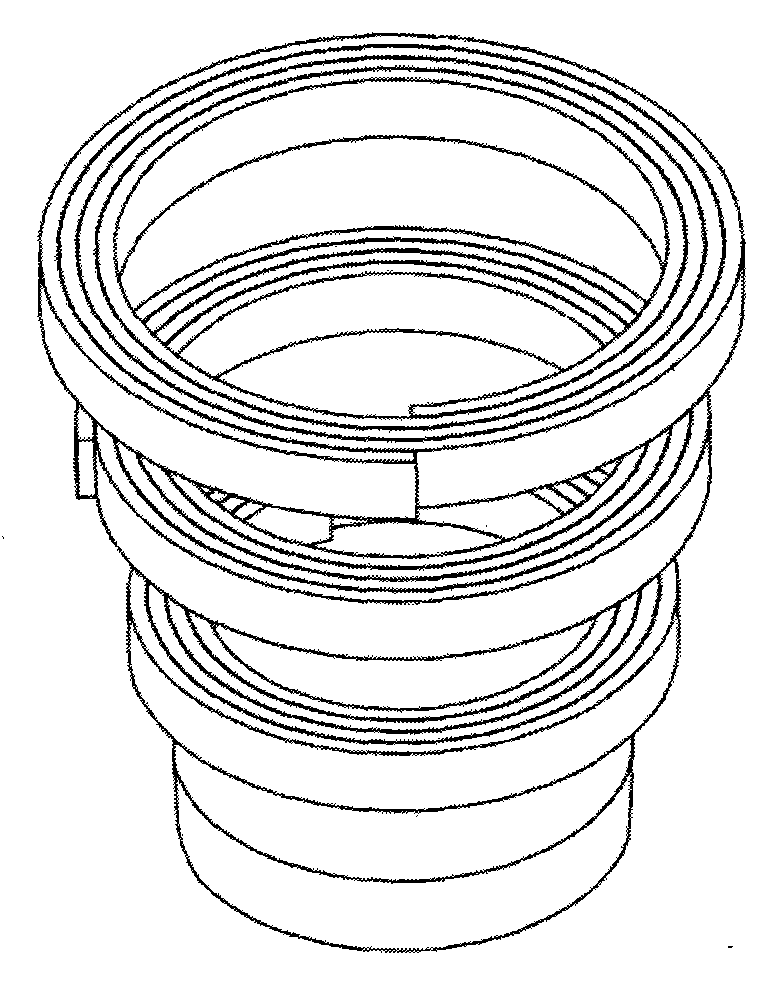

[0032] Depend on figure 1 , figure 2 , It can be seen that a bamboo bowl includes a bowl wall and a bowl bottom, wherein the bowl bottom is made of flat or side-pressed bamboo boards, and the bowl wall is a stack of bamboo rings made of bamboo strips. Wherein said bamboo bowl is made of moso bamboo.

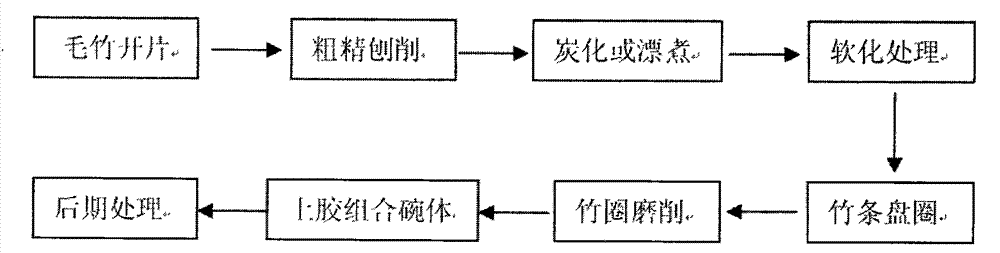

[0033] A kind of production technology of above-mentioned bamboo bowl, it comprises the steps:

[0034] 1. Slicing of moso bamboo: split the whole moso bamboo into 1.0-3.0cm wide strips, the length depends on the free length of moso bamboo;

[0035] 2. Rough and fine planing: rough and fine planing, remove bamboo green and bamboo yellow, the thickness reaches about 0.3-1.0cm, and remove the unqualified bamboo strips after fine planing;

[0036] 3. Carbonization or blanching: carbonize the bamboo strips in a carbonization furnace, the carbonization tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com