Complete set of electrocatalytic reaction device and treatment method for treating high-salt and high-ammonia-nitrogen wastewater

A complete set of equipment and electrocatalytic technology, applied in chemical instruments and methods, water/sewage treatment, special compound water treatment, etc., can solve the problems of low treatment efficiency, large dosage of drugs, and large safety hazards of drug storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

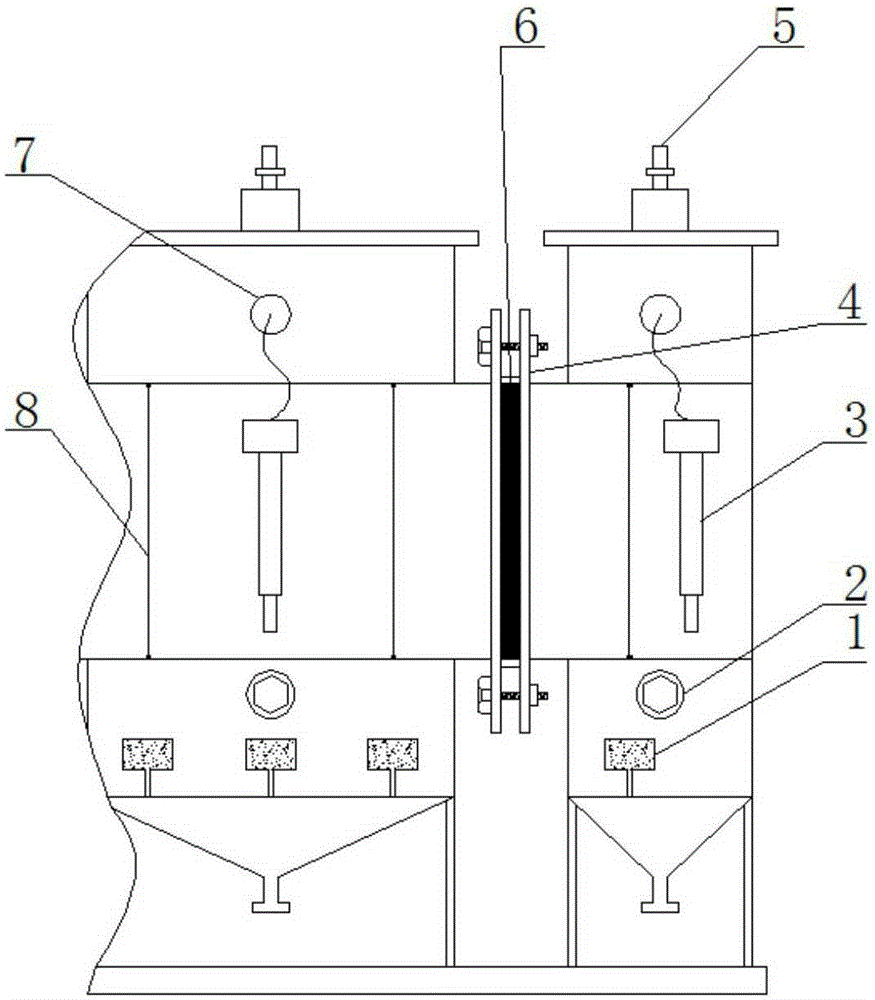

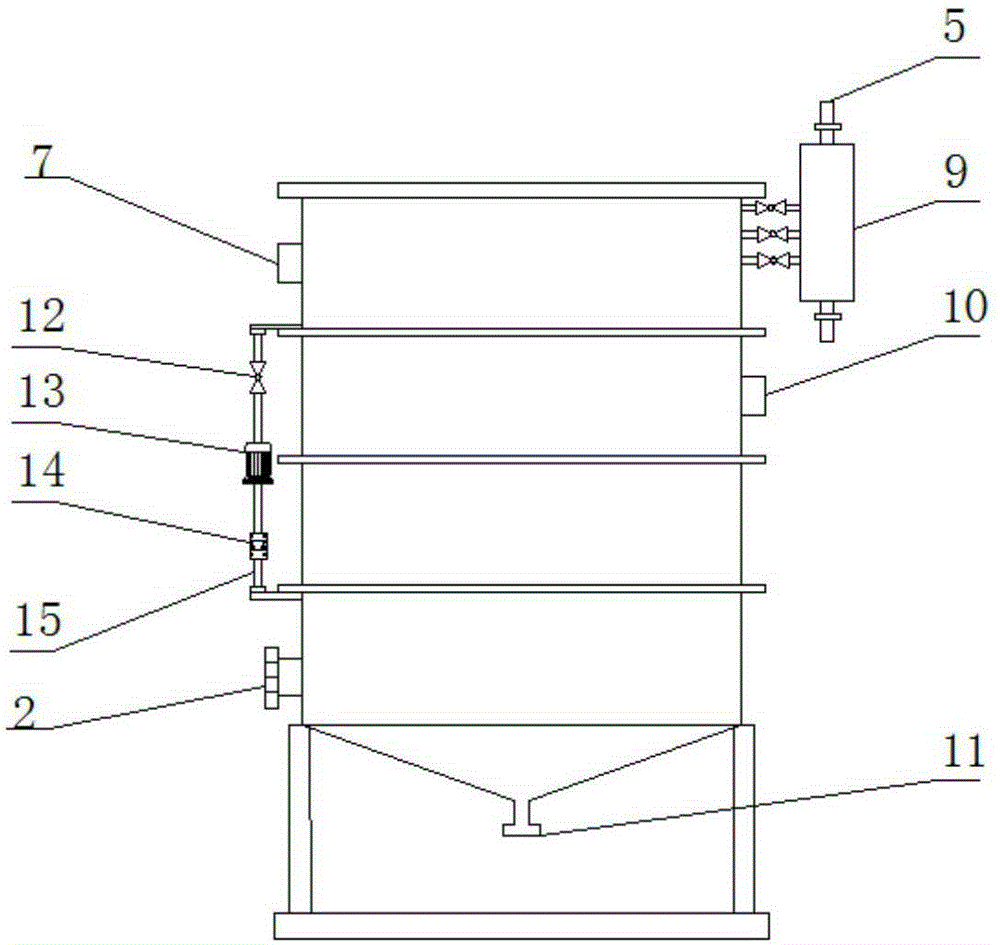

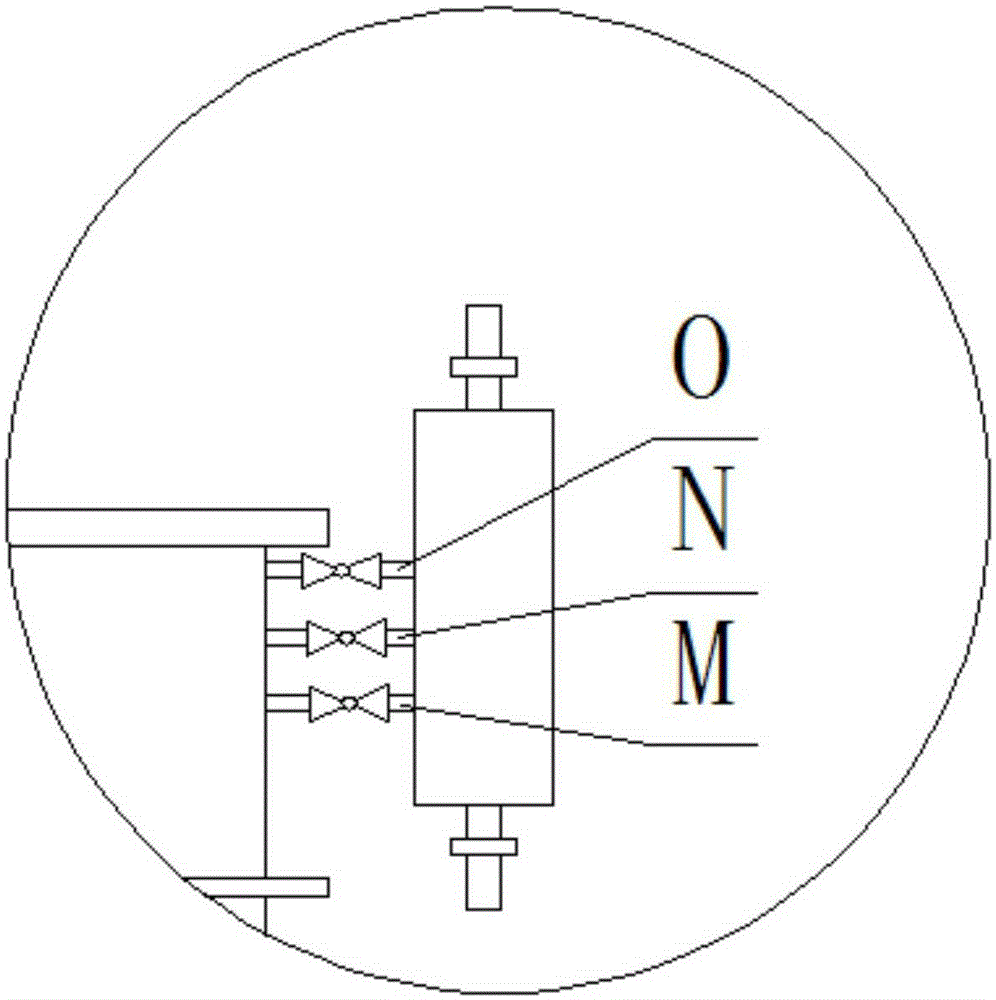

[0036] Such as Figure 1-5 As shown, the complete electrocatalytic reaction device of the present invention uses a periodic phase-commutation DC power supply (not shown in the figure), which is connected to the plate-type DSA plate 8 through the electrode cable interface 10, and the phase-commutation period is controlled to 5-24h. The main body of the electrocatalytic reaction complete set is divided into several cathode and anode chambers (G, H, I, J, K, L) by the ion-selective permeable membrane 6, and there are two plate-type DSA electrodes with the same polarity inside each chamber. The plates 8 are distributed at both ends of each electrode chamber, and the two sides of the ion selective permeable membrane 6 are two different polar plate DSA plates 8, and the plates are preferably prepared by immobilizing precious metal substances on the surface of titanium substrates The formed mesh-shaped noble metal pole plate is preferably composed of one or more of platinum, rutheniu...

Embodiment 2

[0043] The refinery wastewater indicators of a petrochemical company in Tianjin are as follows: ammonia nitrogen: about 1000mg / L, conductivity: 40000μs / cm, Cl - : about 3000mg / L, COD: about 800mg / L, which belongs to high-salt and high-ammonia-nitrogen wastewater, which is difficult to carry out biochemical treatment. The engineering application research on the treatment of ammonia-nitrogen wastewater in this enterprise was carried out by using a complete set of electrocatalytic reaction equipment and related supporting processes. The results show that when When the water and electricity consumption per ton is 8kw.h / t, the effluent ammonia nitrogen ≤ 10mg / L, COD ≤ 50mg / L, meeting the discharge water quality requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com