Production method of naphthenic oil

A production method and technology for naphthenic oil, which are applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of high requirement of hydrotreating pretreatment of raw oil, high hydrogenation pressure, and complex overall process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

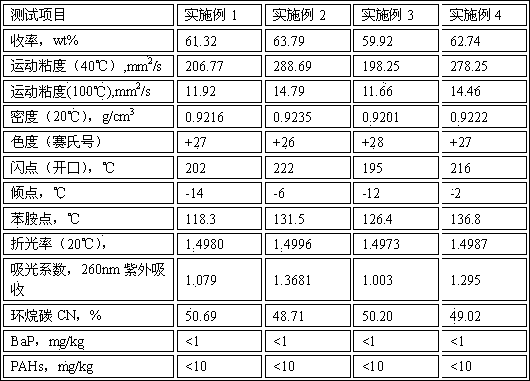

Examples

Embodiment 1

[0023] The second-line distillate oil of Suizhong 36-1 naphthenic crude oil is used as raw material, N-methylpyrrolidone is used as solvent, the volume ratio of solvent N-methylpyrrolidone and the second-line distillate oil of naphthenic crude oil is 1.0:1, and mixed Evenly, put it in a settling tank for constant temperature sedimentation and layering. The settling temperature is 50°C and stay for 30 minutes to obtain the upper liquid and the lower liquid. The refined oil is obtained after recovery of the solvent N-methylpyrrolidone by pressure distillation. Then use the refined oil as the raw material, carry out the hydrofining reaction in the reactor, the catalyst is RN-32, the weight ratio of the catalyst to the refined oil is 0.2:1, the reaction temperature is 350°C, the hydrogenation pressure is 10MPa, the reaction time After 2 hours, the liquid after the reaction was simply stripped and filtered to obtain a colorless and transparent naphthenic oil.

Embodiment 2

[0025] The third-line distillate oil of Suizhong 36-1 naphthenic crude oil is used as raw material, and furfural is used as solvent. The volume ratio of solvent furfural and the third-line distillate oil of naphthenic crude oil is 1.2:1. Constant temperature sedimentation and stratification, settling temperature 55°C, residence time 1h, to obtain the upper liquid and the lower liquid, the lower liquid was distilled under reduced pressure at 20 Torr to recover the solvent to obtain extracted oil, and the upper liquid was distilled under reduced pressure at 20 Torr to recover the solvent furfural to obtain refined oil . Then use the refined oil as the raw material, carry out the hydrofining reaction in the reactor, the catalyst is RN-32, the weight ratio of the catalyst to the refined oil is 0.25:1, the reaction temperature is 350°C, the hydrogenation pressure is 10MPa, the reaction time After 2 hours, the liquid after the reaction was simply stripped and filtered to obtain a co...

Embodiment 3

[0027] The second-line distillate oil of Suizhong 36-1 naphthenic crude oil is used as the raw material, and N-methylpyrrolidone is used as the solvent. The volume ratio of solvent N-methylpyrrolidone and the second-line distillate oil of naphthenic crude oil is 1.5:1. Uniformity, placed in a settling tank for constant temperature sedimentation and stratification, settling temperature 55 ° C, residence time 30 minutes, to obtain the upper liquid and lower liquid, the lower liquid was distilled under reduced pressure at 50 Torr to recover the solvent to obtain the extracted oil, the upper liquid was decompressed at 50 Torr The refined oil is obtained after recovering the solvent N-methylpyrrolidone by distillation. Then use the refined oil as the raw material, carry out the hydrofining reaction in the reactor, the catalyst is RN-32, the weight ratio of the catalyst to the refined oil is 0.2:1, the reaction temperature is 360°C, the hydrogenation pressure is 10MPa, the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com