Single-frame type impeller of wind turbine

A wind-driven generator and single-frame technology, applied to wind-driven engines, wind-driven engines consistent with the wind direction, wind-driven engine control, etc., can solve the problems of long cost recovery period, increased sway, and friction loss between steel ropes and frame grooves Large and other problems, to achieve the effect of improving wind energy utilization efficiency, increasing output power, and facilitating daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

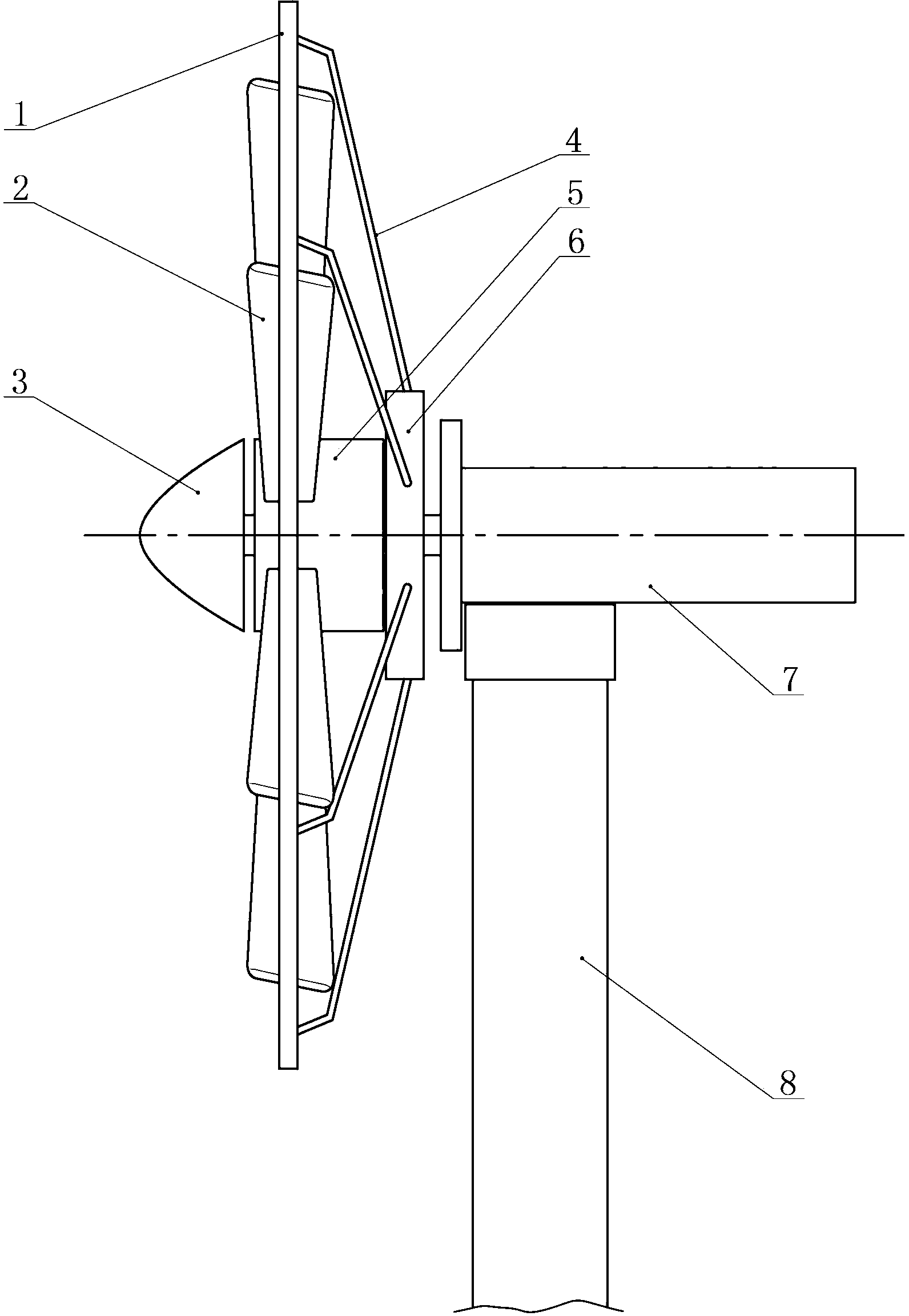

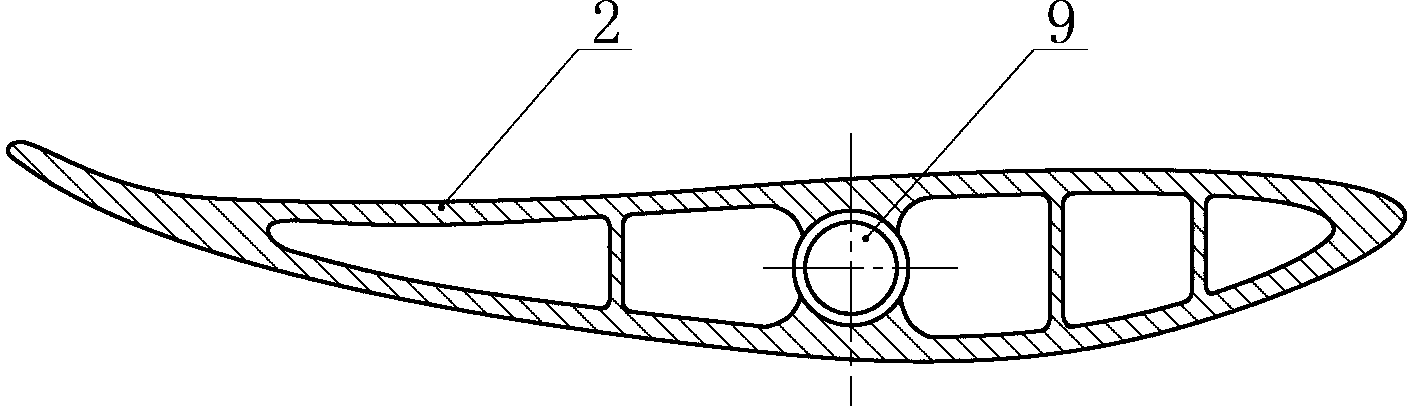

[0026] Depend on Figure 1 ~ Figure 4 It can be seen that the technical solution of the present invention includes the generator 7, the wind rotor frame 1, the blade 2, the support seat 6, the inclined support rod 4, and the blade adjustment device with the main shaft horizontally arranged; the generator 7 is assembled on the top of the pole tower 8;

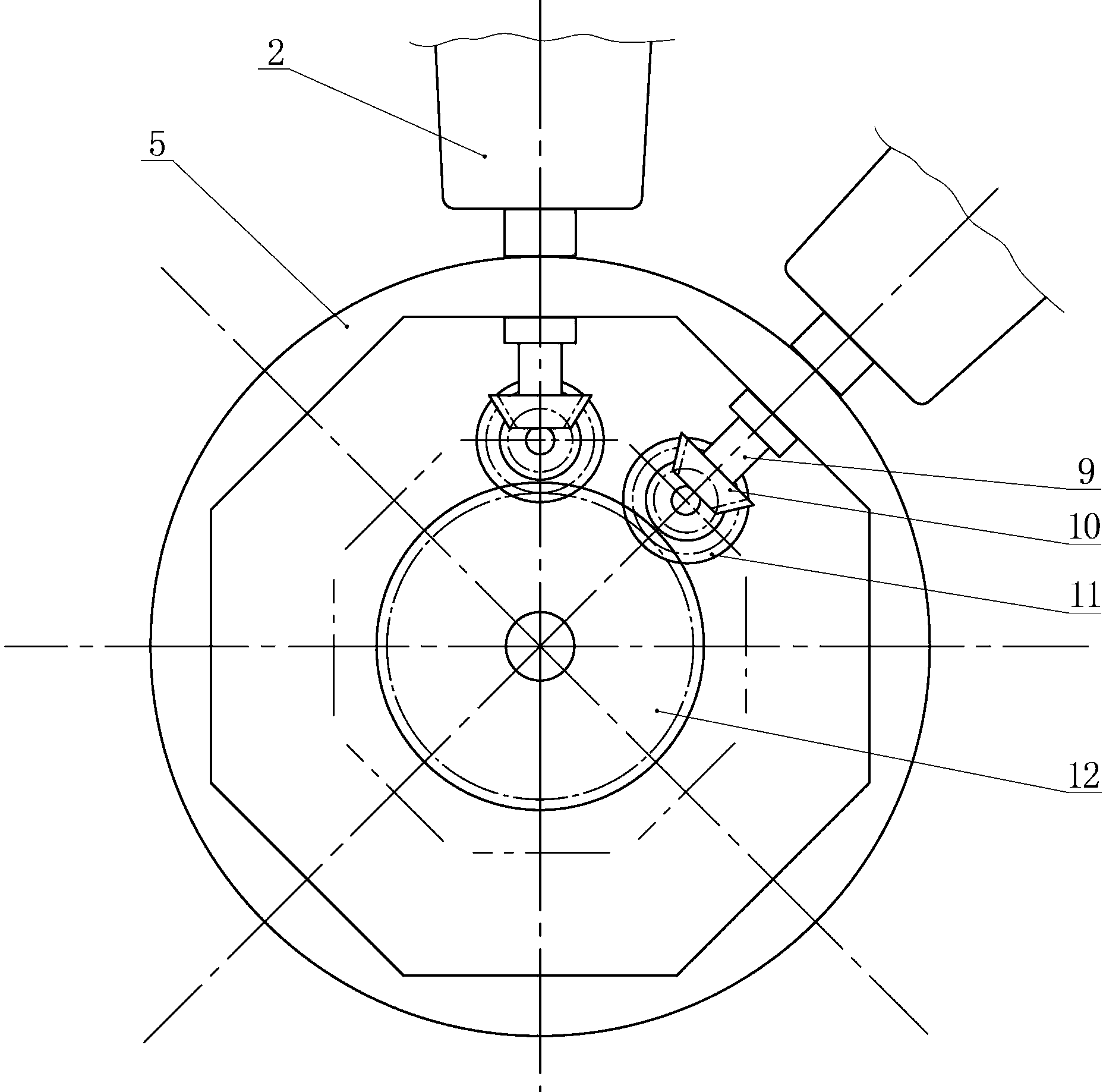

[0027] The blade adjustment device includes a blade adjustment chamber 5, a power unit, and an adjustment mechanism; the blade adjustment chamber 5 is horizontally cylindrical, and the rear end of the blade adjustment chamber 5 is connected and fixed on the front of the support seat 6, and the blade adjustment chamber 5 and the support seat 6 are integrated. , assembled at the front end of the main shaft of the generator, and rotates with the main shaft; the supporting base 6 is connected with the wind rotor frame 1 through the inclined support rod 4, so that the blade adjustment chamber 5 is located in the center of the wind rot...

Embodiment 2

[0032] In this embodiment, a large-scale wind generator with a larger output power is taken as an example, and the Figure 5 ~ Figure 7It can be seen that the difference between this embodiment and Embodiment 1 is that due to the large volume and weight of the fan, three spoke-type poles 13 are connected and fixed between the blade adjustment chamber 5 and the wind wheel frame 1. The shape of "" is evenly distributed to enhance the strength and wind resistance of the wind wheel; the adjustment mechanism of the blade adjustment device adopts a link-type adjustment mechanism, which includes a push-pull transmission mechanism, an adjustment frame 19, a rotating arm 20, and a connecting rod 21 The push-pull transmission mechanism is composed of swing arm 16, positioning shaft 15, main drive arm 17, and push-pull rod 18; the inner side of the blade adjustment chamber 5 cylindrical side walls is provided with a circle of annular guide rails, and the adjustment frame 19 is assembled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com