Multi-beam Optical Thick Film Monitor

A monitor and multi-beam technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of low monitoring accuracy, poor monitoring efficiency, and few monitoring points, so as to achieve more monitoring points, improve yield rate, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

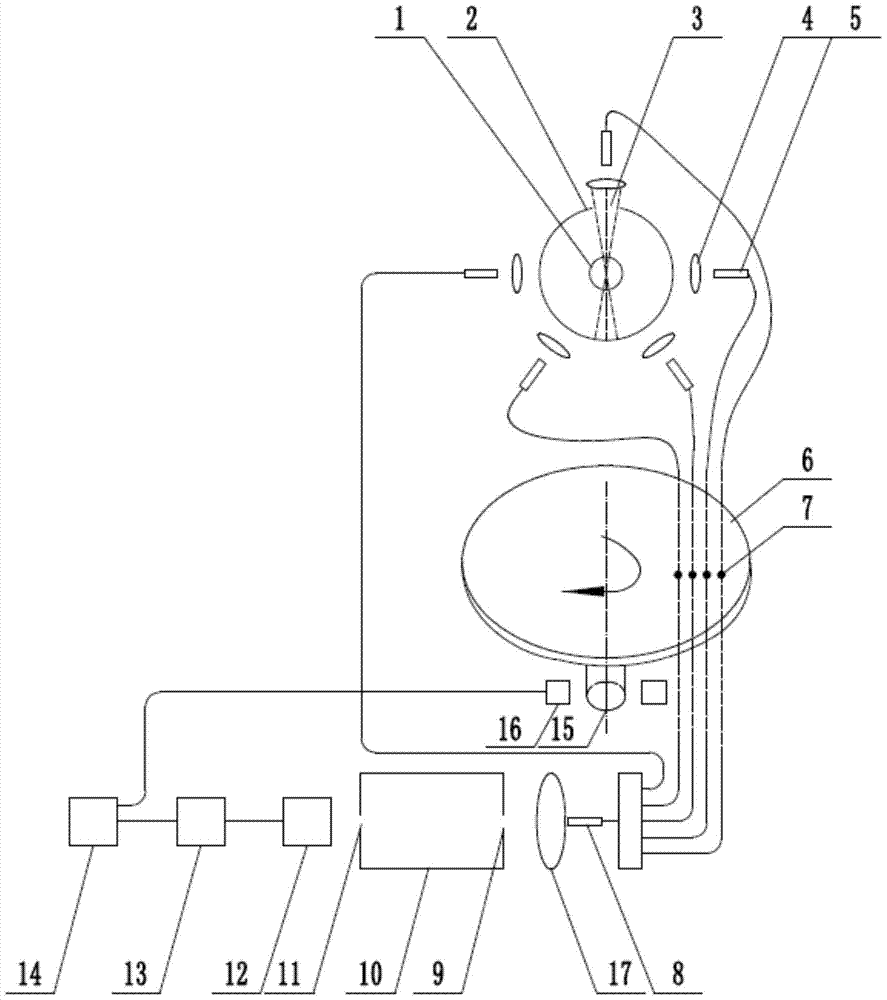

[0017] like figure 1 As shown, the multi-beam optical thick film monitor in this embodiment includes a monochromator 10, a photodetector 12, a signal amplifier 13, a control computer 14, a position trigger circuit 16 and a converging lens 17, wherein: it also includes :

[0018] A tungsten-halogen lamp 1: the tungsten-halogen lamp 1 is set in the annular rotary chopper 2;

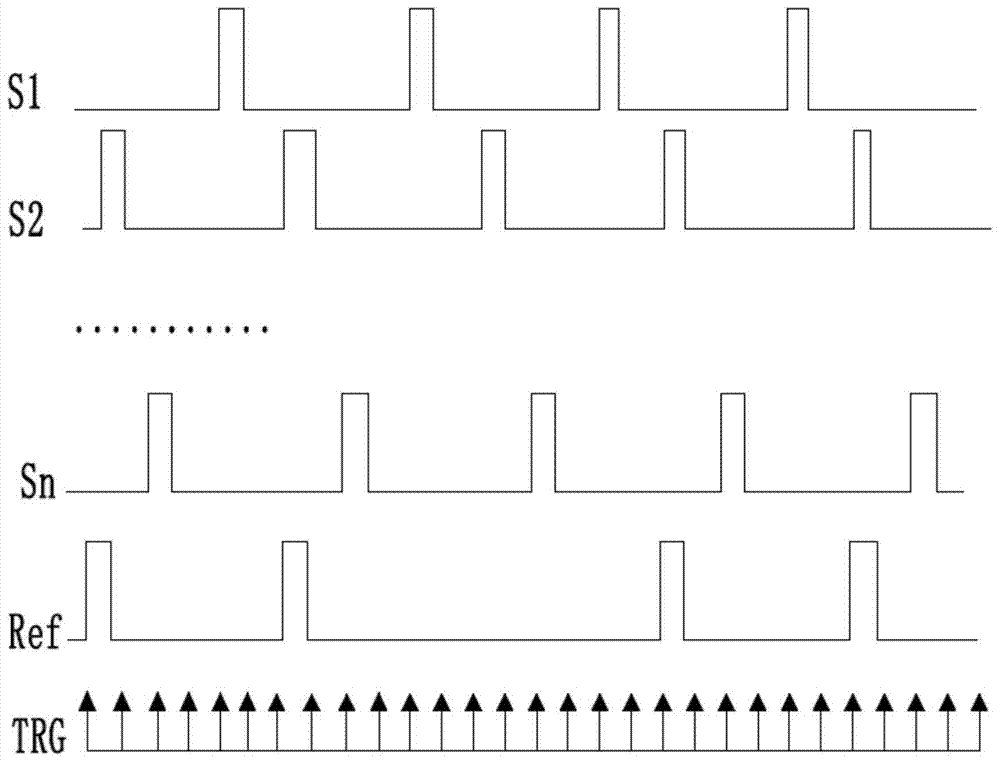

[0019] A ring-shaped rotary light chopper 2: the circular ring-shaped rotary light chopper 2 is set on a rotating tray and can rotate around the filament of the tungsten-halogen lamp 1; A light exit hole 3, a photoelectric switch or an encoder is coaxially connected to the axis of the annular rotary chopper 2 to set trigger pulses for each optical path and dark field position for selecting the corresponding signal processing circuit;

[0020] Five optical fiber optical paths: each optical fiber optical path is composed of a lens 4 and an optical fiber 5. The optical fiber optical path is centered on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com