Silver/silver chloride reference electrode and manufacturing method of reference electrode

A reference electrode and silver chloride technology, applied in the direction of material electrochemical variables, can solve the problems of reducing the stability and reproducibility of the reference electrode, the easy oxidation of the silver electrode, and the volatilization loss of silver chloride, etc., to achieve Cheap raw materials, good airtightness, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

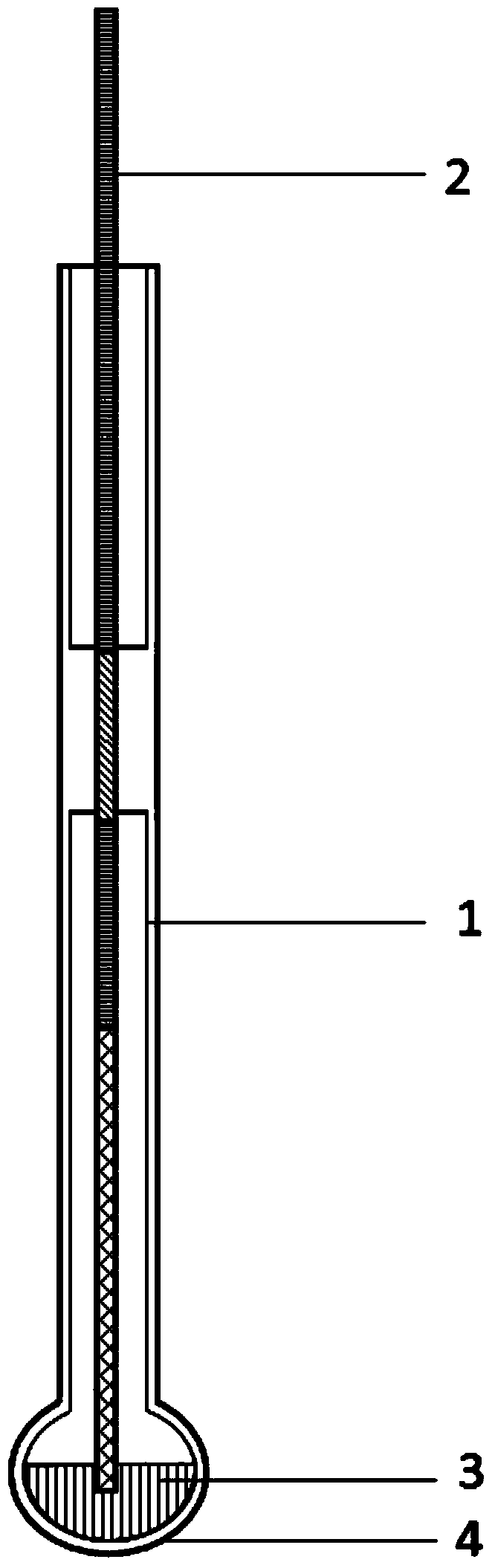

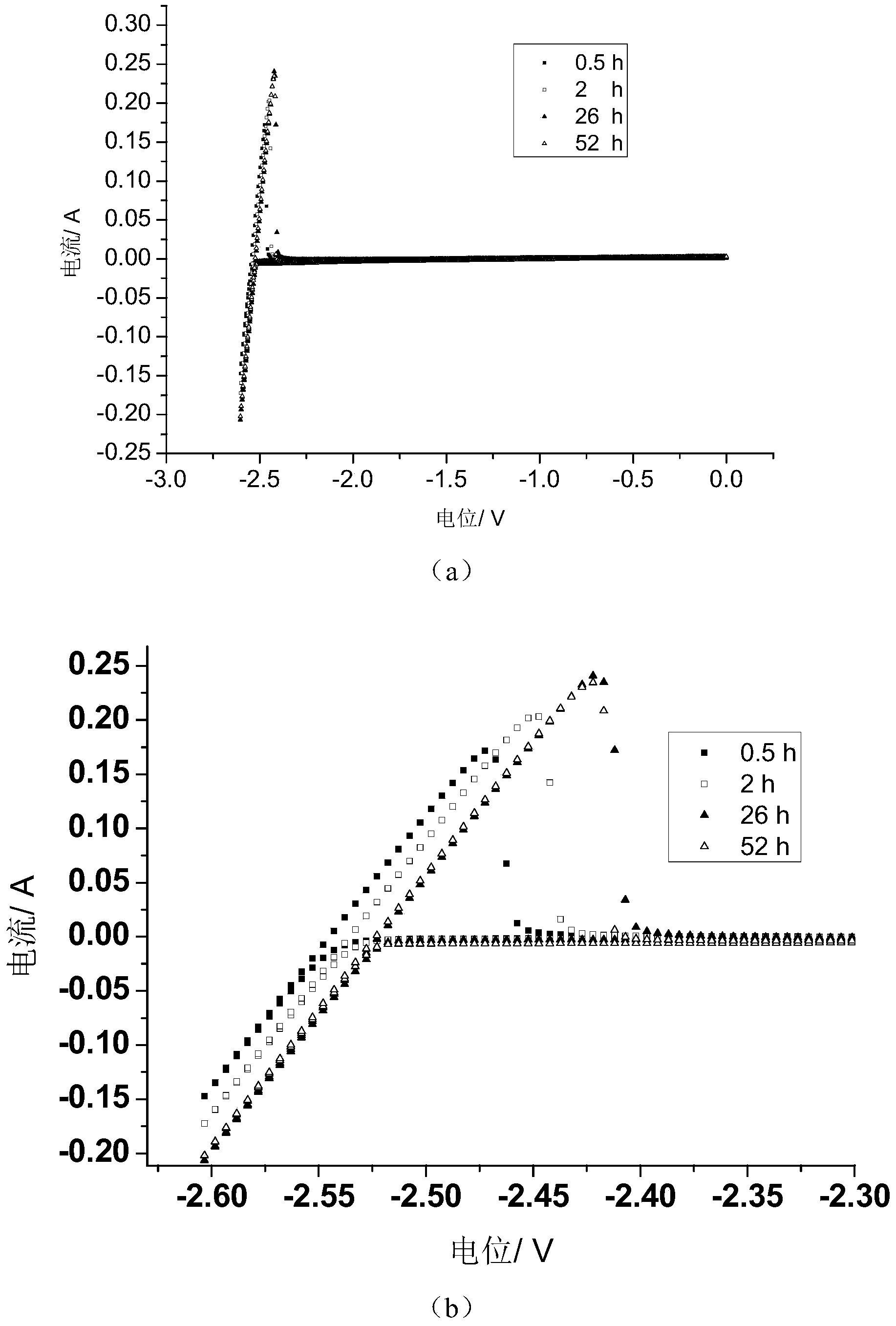

[0048] Embodiment 1 The making of reference electrode of the present invention

[0049] (1) Accurately weigh 10 grams of lithium chloride, potassium chloride, and silver chloride with a substance ratio of 59:41:5, dry under reduced pressure at 300°C for 3 hours, grind until the particle size reaches 200 mesh and mix Uniform, standby as reference salt 3 for making reference electrode;

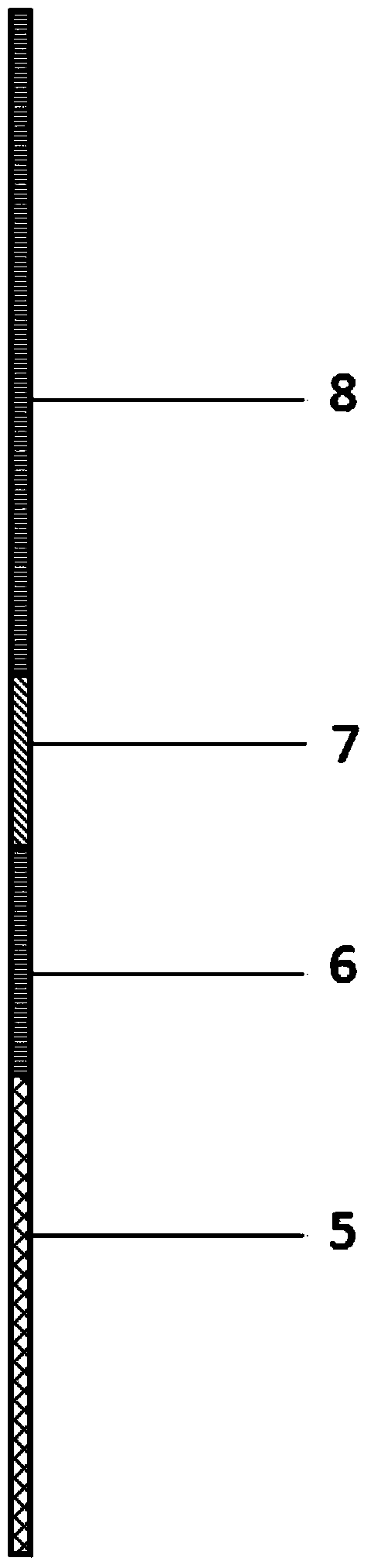

[0050] (2) getting a diameter of 1 mm and a length of 4 cm cylindrical A section 5 (in the present embodiment, the material of the A section is silver, and a shape of silk), a diameter of 1 mm and a length of 1 cm cylindrical B section 6 (the present embodiment The material of the middle B section is nickel, and the shape is filamentous), the diameter is 1mm and the length is 1cm cylindrical C section 7 (the material of the C section in this embodiment is tungsten, and the shape is filamentous) and the diameter is 1mm and the length is 4cm Cylindrical D section 8 (in the present embodiment, the...

Embodiment 2

[0056] Embodiment 2 The making of reference electrode of the present invention

[0057] (1) Accurately weigh 10 grams of lithium chloride, barium chloride, and silver chloride with a substance ratio of 67:28:5, dry under reduced pressure at 300°C for 3 hours, grind until the particle size reaches 200 mesh and mix Uniform, standby as reference salt 3 for making reference electrode;

[0058] (2) get the cylindrical stainless steel wire 6 that the length of 1 mm in diameter is 4 cm (the material of segment A is silver in the present embodiment, and the shape is silk), the length of 1 mm in diameter is 1 cm, and the length of 1 mm is 1 mm in diameter. The cylindrical C section 7 that length is 1cm (in the present embodiment, the material of C section is molybdenum, and the shape is filiform) and diameter is that 1mm length is each one section of cylindrical stainless steel wire 8 of 4cm, according to such as figure 2 In the sequence shown, the four sections of metal wire are fab...

Embodiment 3

[0064] Embodiment 3 The making of reference electrode of the present invention

[0065] (1) Accurately weigh 10 grams of sodium chloride, magnesium chloride, and silver chloride with a substance ratio of 57:38:5, dry under reduced pressure at 300°C for 3 hours, grind until the particle size reaches 200 mesh and mix evenly, Standby as the reference salt 3 for making the reference electrode;

[0066] (2) getting a diameter of 1 mm and a length of 4 cm cylindrical A section 5 (in the present embodiment, the material of the A section is silver, and a shape of silk), a diameter of 1 mm and a length of 1 cm cylindrical B section 6 (the present embodiment The material of the middle B section is nickel, and the shape is filamentous), the diameter is 1mm and the length is 1cm cylindrical C section 7 (the material of the C section in this embodiment is tungsten, and the shape is filamentous) and the diameter is 1mm and the length is 4cm Cylindrical D section 8 (in the present embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com