Automatic test system for onboard cable integrity

An automatic testing system and integrity technology, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve the problems of high false detection and missed detection rate, large human error, low testing efficiency, etc., to achieve simple operation, The effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

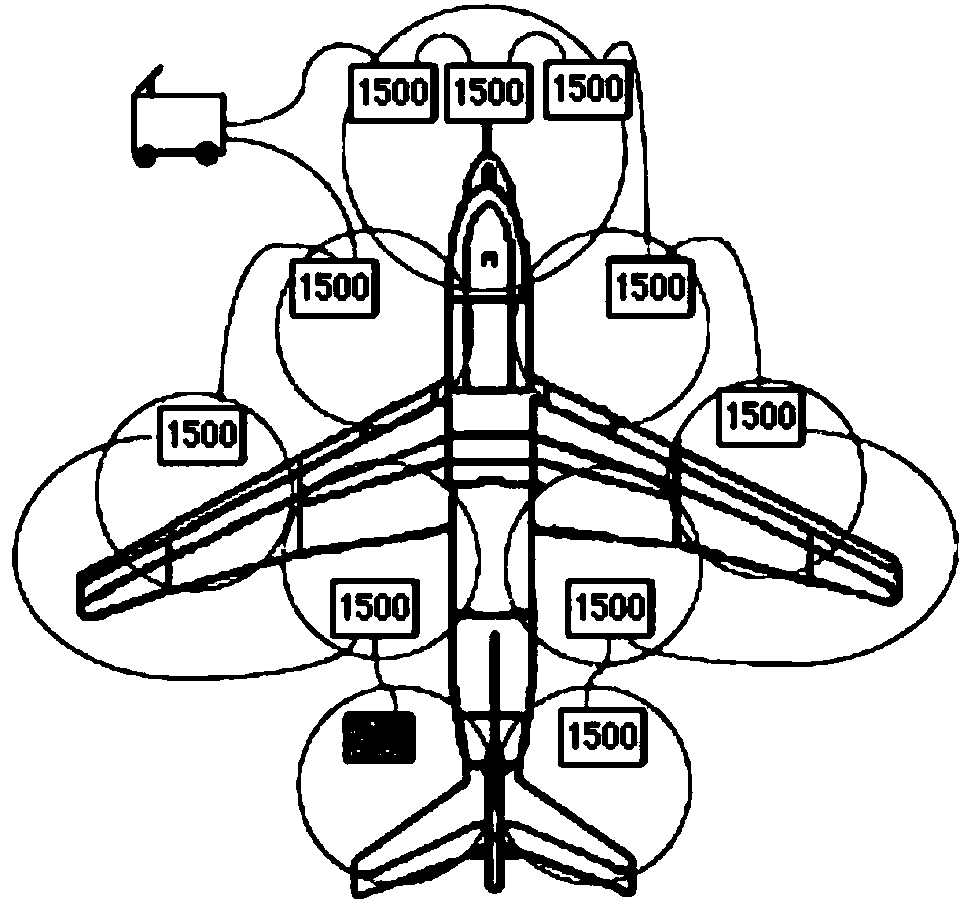

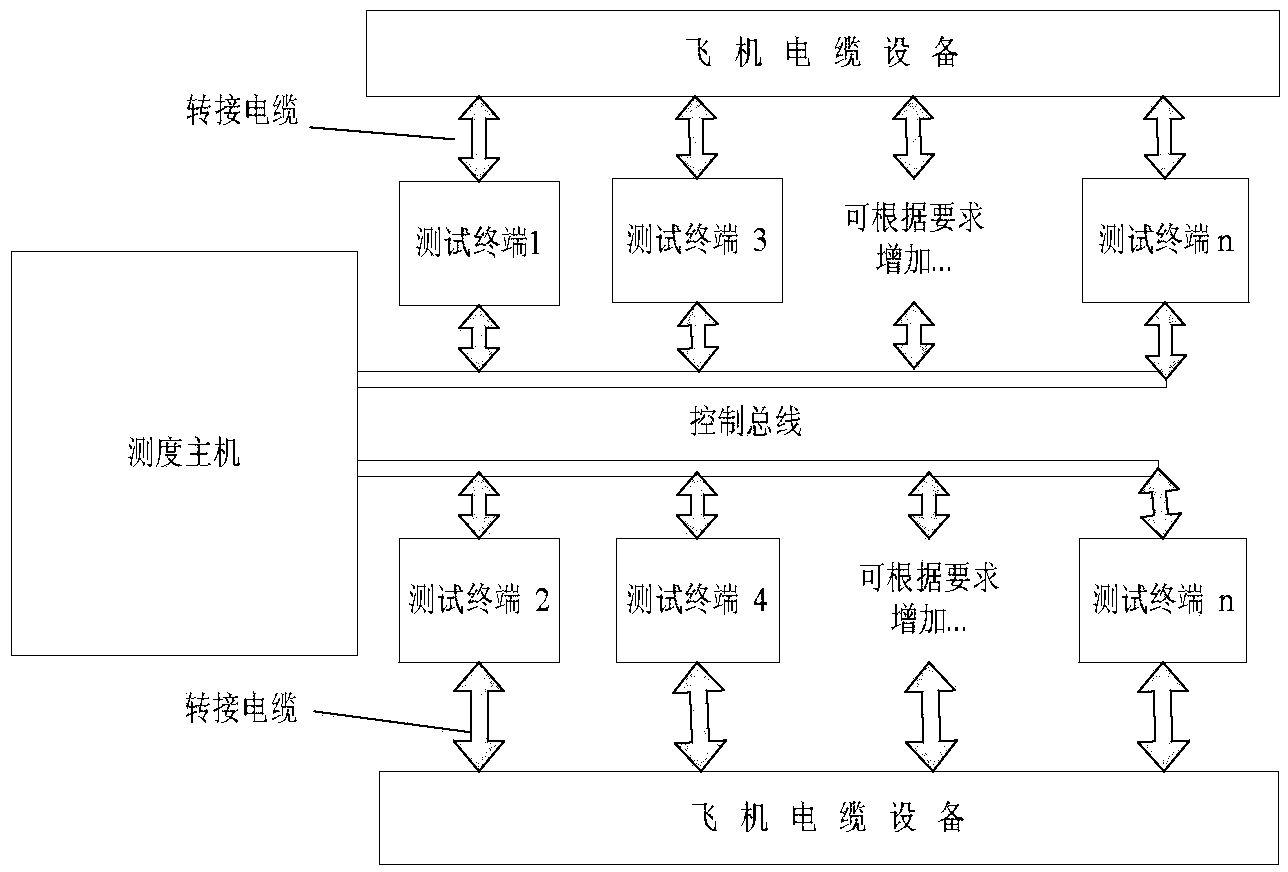

[0030] Such as Figure 1a , Figure 1b The schematic diagram of the on-board cable integrity automatic test system shown is composed of a test host, test terminals, transfer cables, and cable equipment to be tested. The system adopts a distributed measurement scheme, which can automatically identify the location of the transfer cable and automatically give the test address. The test terminal can be arranged in the parts of the aircraft that need to be tested according to the test requirements, such as the front fuselage, wing and engine, so as to shorten the length of the transfer cable, reduce the cost of the transfer cable, and improve the test efficiency.

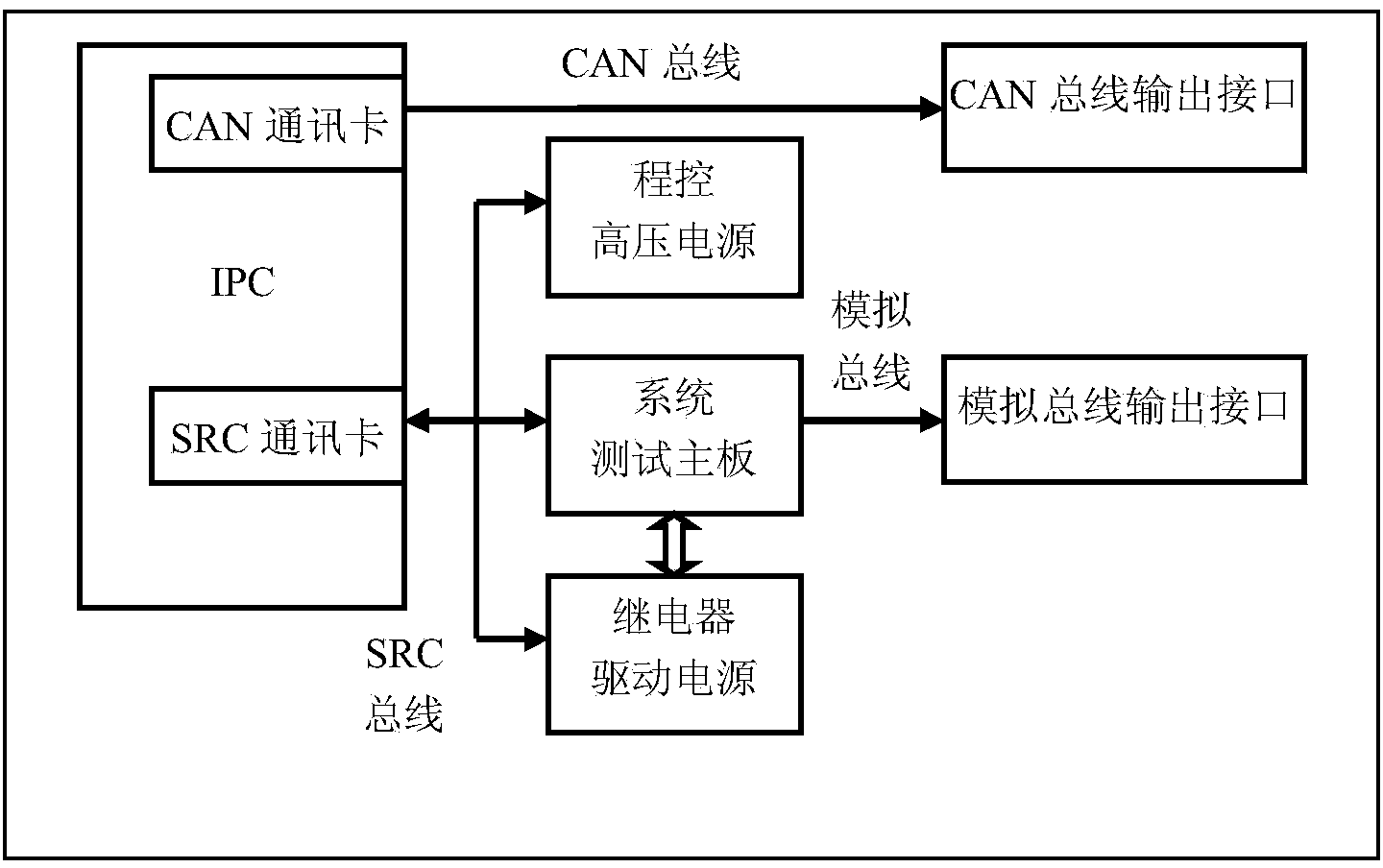

[0031] The on-board cable integrity automatic test system uses CAN bus technology to build a distributed communication and control network between the test host and the test terminal to achieve the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com