Laser tail lens assembly for selecting angular polarization

A technology of angular polarization and lasers, applied in the field of optics, can solve the problems of low polarization purity of angularly polarized light, complex design and manufacture of grating mirrors, and high price, and achieve excellent thermal stability and mechanical properties, and good polarization selectivity , making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

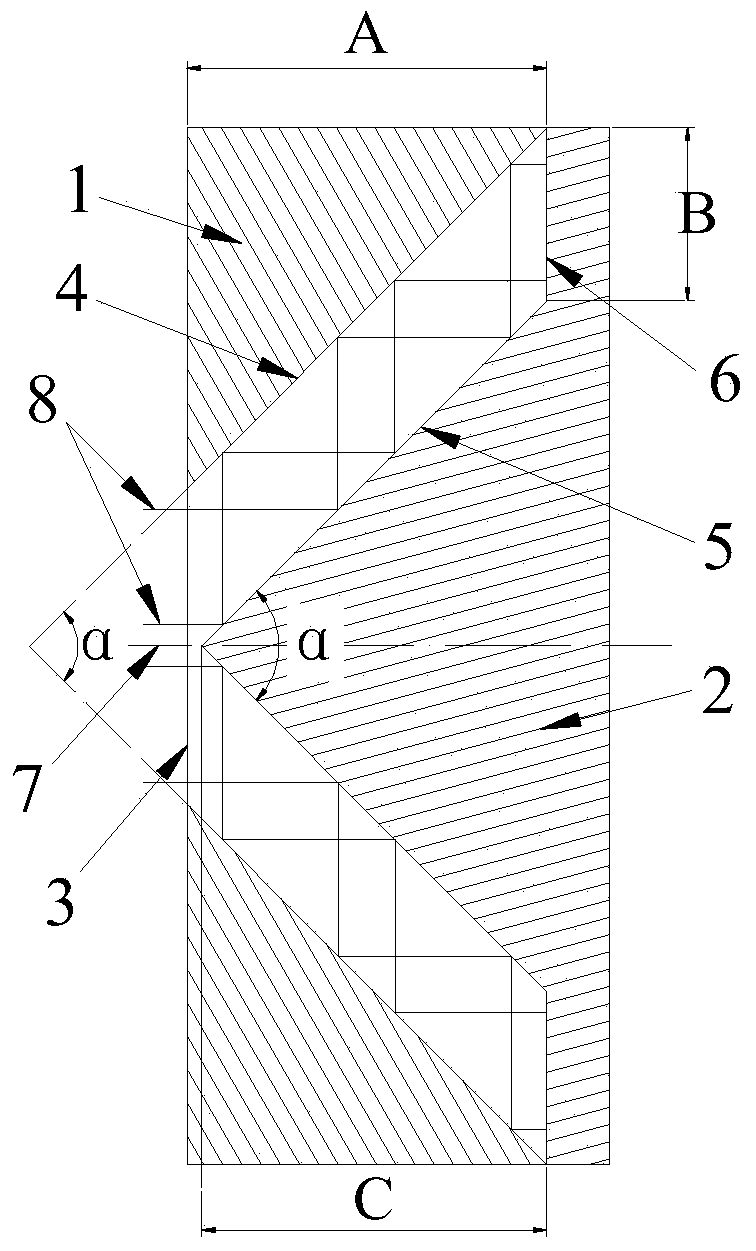

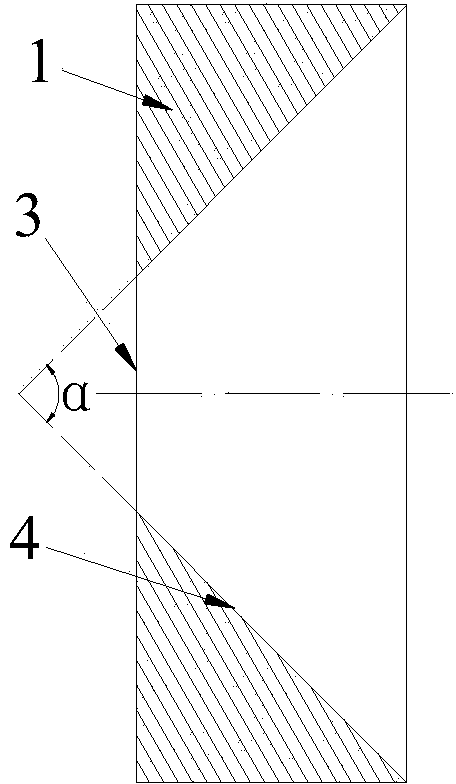

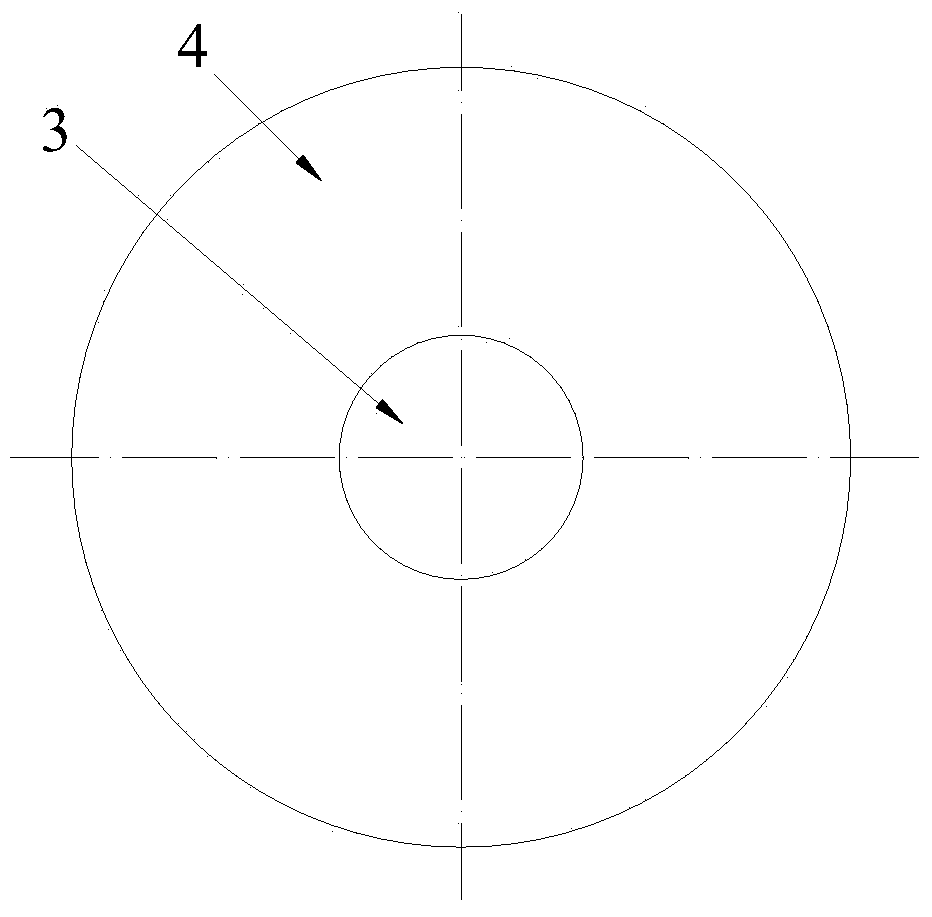

[0021] like Figure 1-5 As shown, the combined mirror structure of the present invention includes an inner cone mirror 1 and an outer cone mirror 2 fixed together and arranged rotationally symmetrically around the optical axis, and an incident hole 3 is opened in the center of the inner cone mirror 1 . Wherein, the inner cone mirror 1 has only an inner cone reflection surface 4, and the outer cone mirror 2 is composed of an outer cone reflection surface 5 and an annular reflection surface 6, and the inner cone reflection surface 4 and the outer cone reflection surface 5 are respectively connected with the ring reflection surface 6 The outer and inner edges meet. The inner cone reflective surface 4 , the outer cone reflective surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com