Board arrangement device and board arrangement method

A technology of arranging and arranging boards, which is applied in the direction of multi-layer circuit manufacturing, circuit lamination, electrical components, etc., can solve problems such as position offset, and achieve the effect of improving the quality of PCB lamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

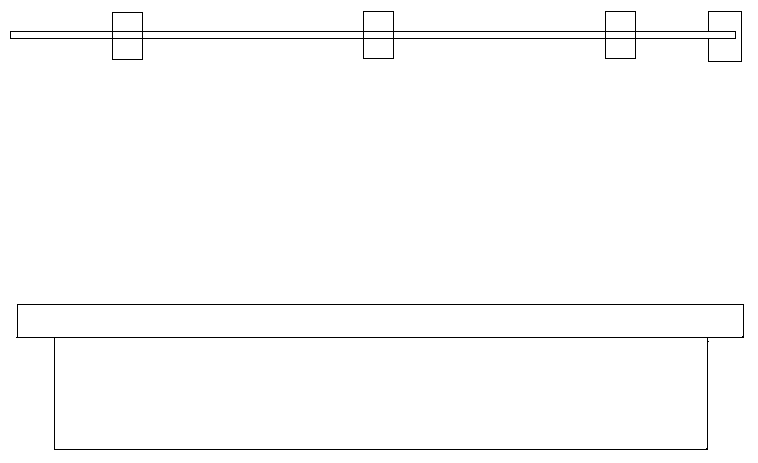

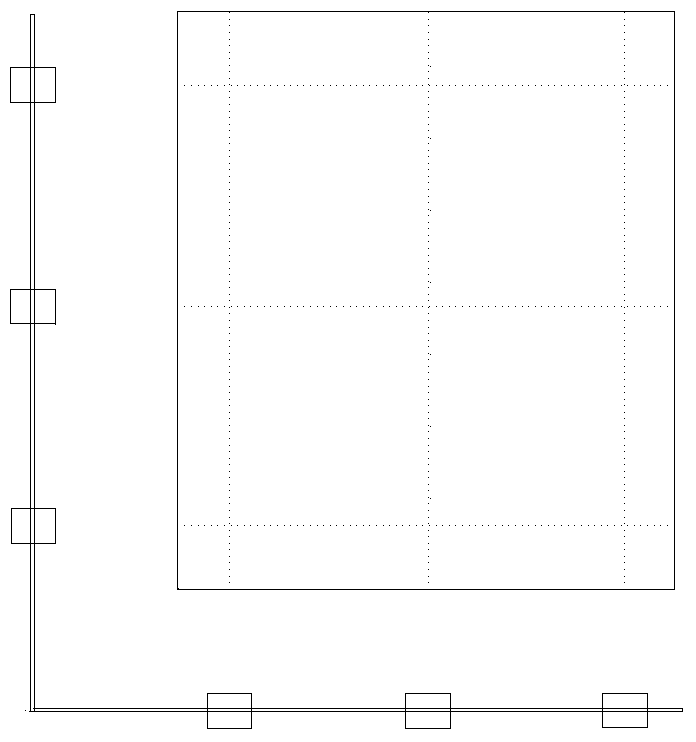

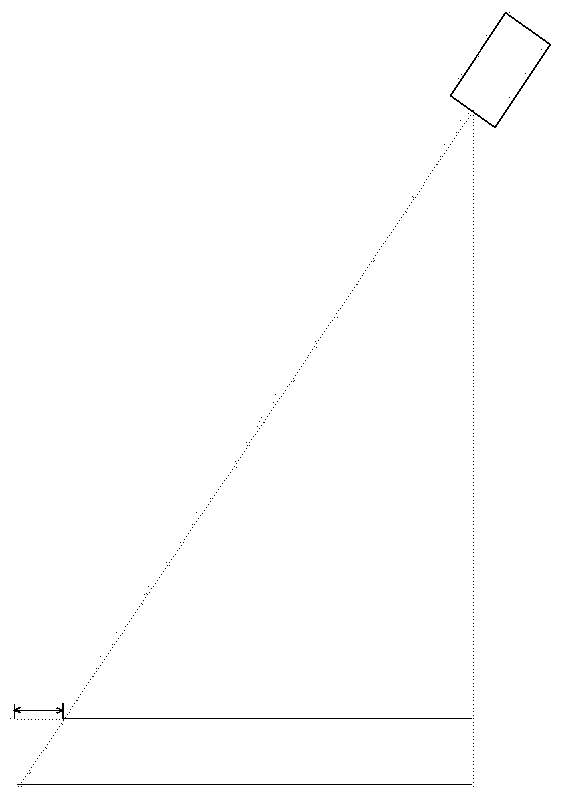

[0031] A kind of arrangement device provided in this embodiment, refer to Figure 5-8 , including a chassis 40 , a rectangular pallet board 20 , a screw lifter 30 , an infrared sensor, eight fixing clips 50 and a positioning line generator 10 . Screw lifter 30 is set on chassis 40, and a row of pallets 20 are installed on screw lifter 30, the height of row pallet platform 20 can be adjusted by screw lifter 30. Two fixing clips 50 are respectively arranged on each side of the palletizing table 20. After each board is stacked on the palletizing table 20 as required, the laminated layers on the palletizing table are clamped and fixed with the fixing clips 50. , forming a plate. An infrared sensor is set beside the pallet table 20 and at the initial height of the table top of the pallet table 20 to sense the height of the pallet table 20, and the pallet device controls the operation of the screw elevator 30 according to the signal of the infrared sensor , each adjustment all mak...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, except that: in 3-2 of the step (3) of the board arrangement process, the prepregs are stacked symmetrically on both sides of the lower copper foil layer to form the first prepreg layer; and by The scale marks on the general positioning wire frame place the first prepreg layer in the middle of the general positioning wire frame, such as Figure 11 shown. Then with reference to the steps from 3-3 to 3-6 of Example 1 and steps (4), (5), respectively stack the inner layer, the second prepreg layer and the upper copper foil layer on the first prepreg layer successively, Thus, the formed inner layer board is provided with two symmetrically placed inner layer boards.

[0050] Use the board arrangement device of Example 1 and the board arrangement method of this embodiment to make a plurality of boards, then move the boards to the press furnace and press the same hot pressing process as in Example 1 to make a multi-layer ...

Embodiment 3

[0052] This embodiment is basically the same as Embodiment 1, except that: in 3-2 of the step (3) of the board arrangement process, three prepregs are equidistantly placed in parallel on the lower copper foil layer to form the first prepreg layer; and Place the first prepreg layer in the middle of the general positioning wire frame through the scale line on the general positioning wire frame, such as Figure 12 shown. Then with reference to the steps from 3-3 to 3-6 of Example 1 and steps (4), (5), respectively stack the inner layer, the second prepreg layer and the upper copper foil layer on the first prepreg layer successively, Thereby, the formed inner layer board is provided with three inner layer boards placed in parallel at equal distances.

[0053] Use the board arrangement device of Example 1 and the board arrangement method of this embodiment to make a plurality of boards, then move the boards to the press furnace and press the same hot pressing process as in Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com