Medium-sized numerical-control gantry structure

A gantry-type, medium-sized technology, used in auxiliary devices, gas flame welding equipment, plasma welding equipment, etc., can solve the problems of insufficient installation accuracy, affecting processing quality, and increasing difficulty in the installation process, achieving stable accuracy, improving cutting quality, Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings.

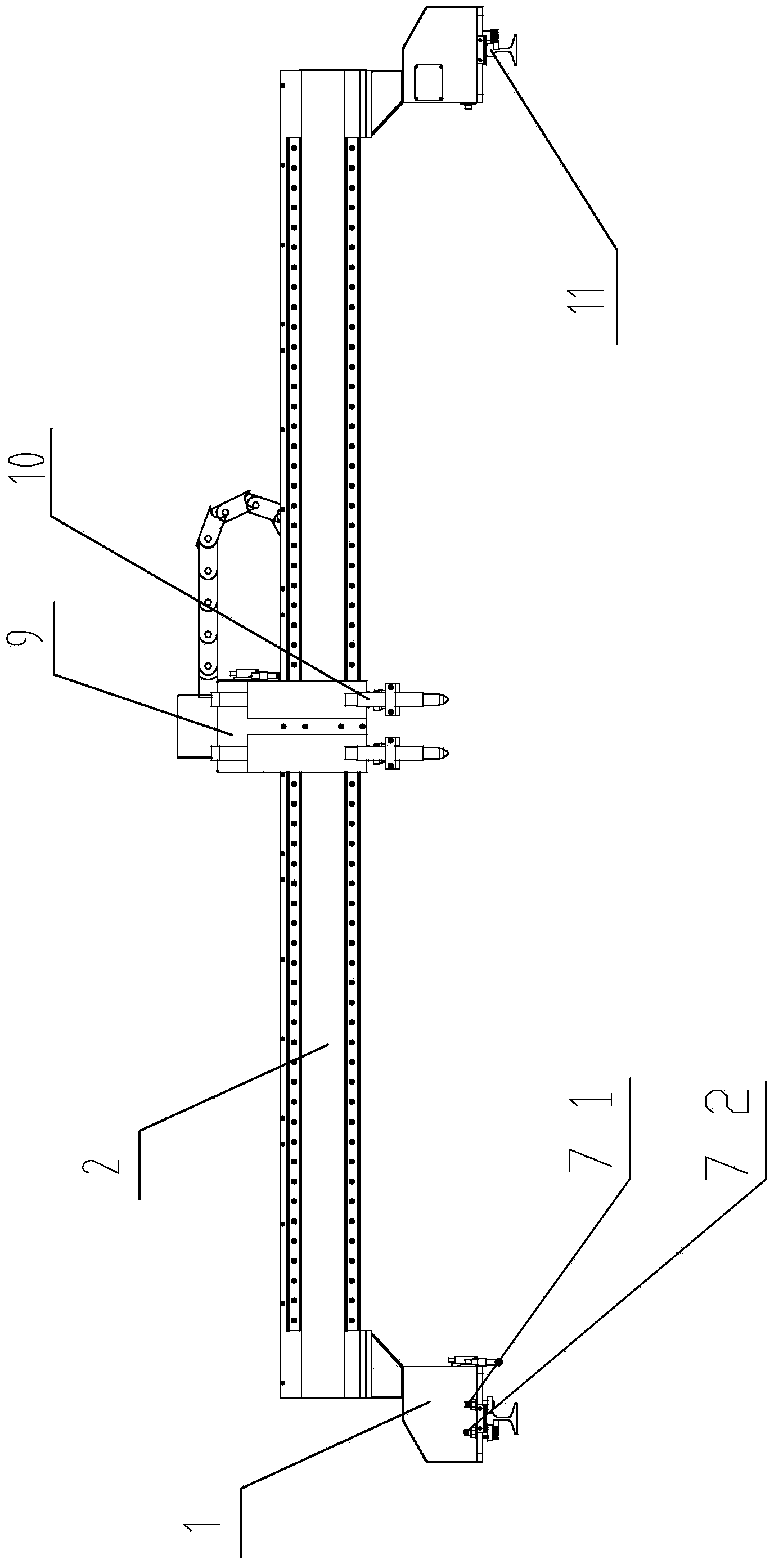

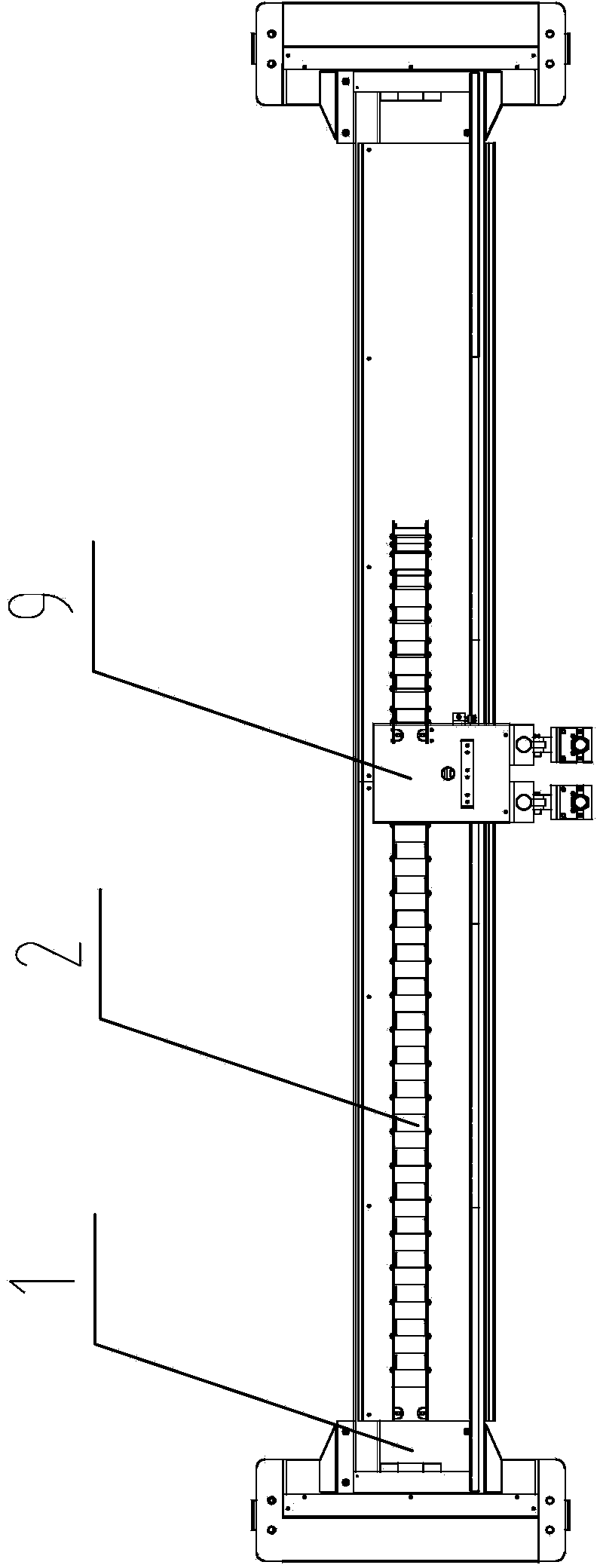

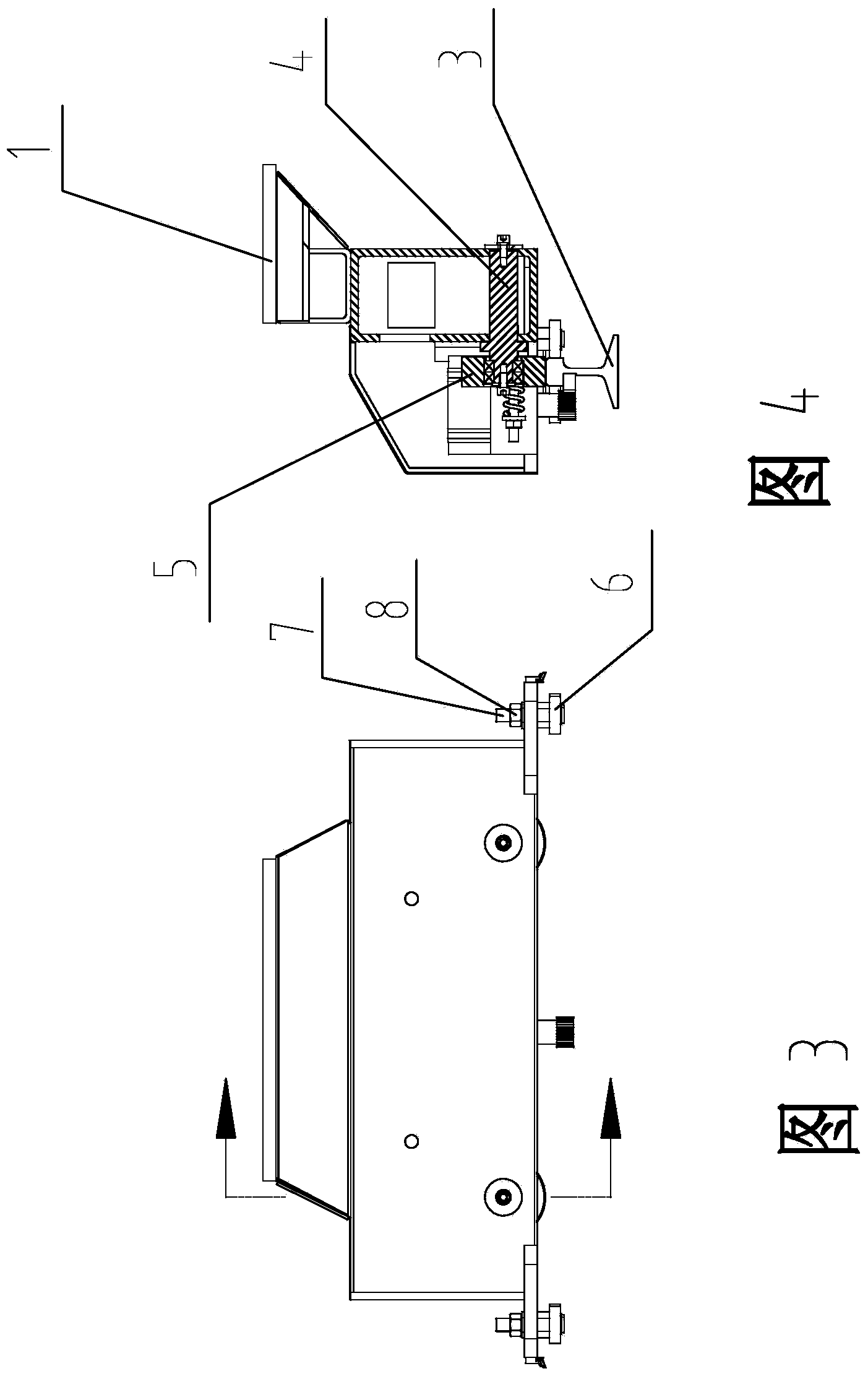

[0013] Such as Figure 1 ~ Figure 4 As shown: the medium-sized CNC gantry structure includes an end beam 1, a beam 2, a light rail 3, a roller shaft 4, a roller 5, a bearing 6, a guide shaft 7, a nut 8, a moving body 9, a torch 10, and a guide rail assembly 11 Wait.

[0014] Such as figure 1 As shown, the present invention includes guide rail assemblies 11 arranged parallel and symmetrically on the left and right sides, and the distance between the left and right two groups of guide rail assemblies 11 is determined according to the required span; Crossbeams 2 are connected between the end beams 1 on the side, and a moving body 9 that can move along the crossbeams 2 is arranged on the crossbeams 2 , and a torch 10 is installed on the moving body 9 . The beam 2 adopts a vertical plate structure.

[0015] Such as image 3 , Figure 4 As shown, the guide rail assembly 11 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com