Quantitative removal method of metal coating by multi-pulse laser ablation

A technology of laser ablation and metal cladding, applied in laser welding equipment, metal processing equipment, instruments, etc., can solve the problems of low efficiency, high cost, and difficult to accurately predict and control the amount of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

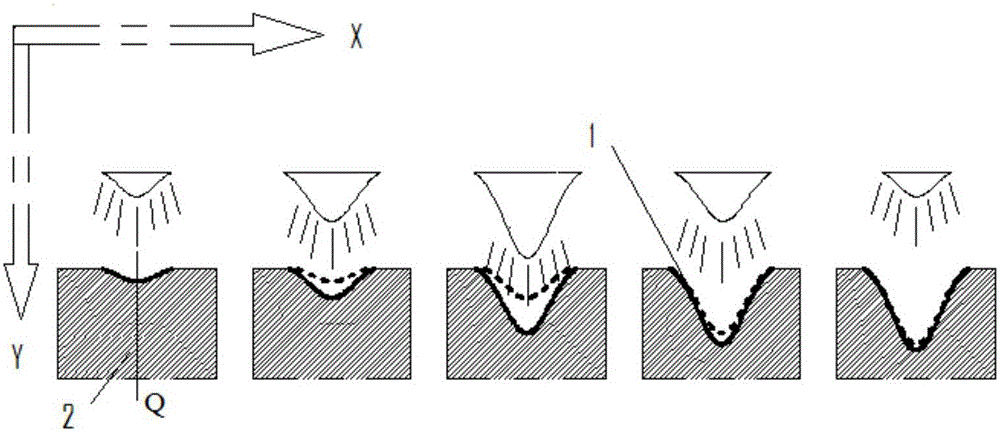

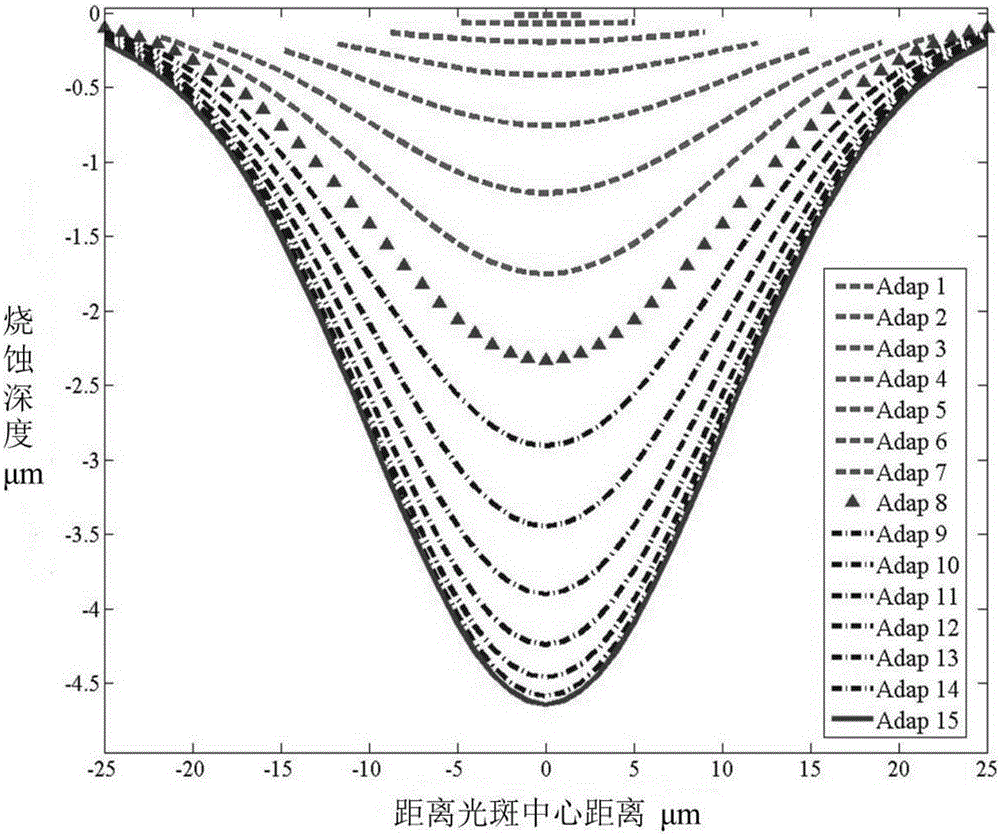

[0026] EXAMPLES The processing and experimental conditions are as follows: the metal coating is a 10 μm thick copper plating layer, the base material is polyimide, the wavelength of the laser light source is 532nm, the pulse width is 10ns, the repetition frequency is 10-40Khz, and the energy density is 0-70J / cm 2 . Feed speed 0-6m / min. The laser spot diameter is 40um. The specific implementation steps of the multi-pulse laser ablation metal coating quantitative removal method are as follows:

[0027] (1) Calculation of material thickness removed by a single pulse

[0028] Since the pulse action time emitted by the laser light source used is nanosecond level, the energy transfer is mainly heat transfer. The heat transfer between cladding metal and engineering plastic is difficult, depending on the heat penetration depth It is calculated that the thermal penetration depth of the pulsed laser energy in the copper layer is less than 2um, which is much smaller than the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com