Double-silver-layer LOW-E (Low-emissivity) glass with simple structure

A technology with simple structure and glass, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve problems such as complex structure, and achieve the effects of stable process, small equipment investment and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

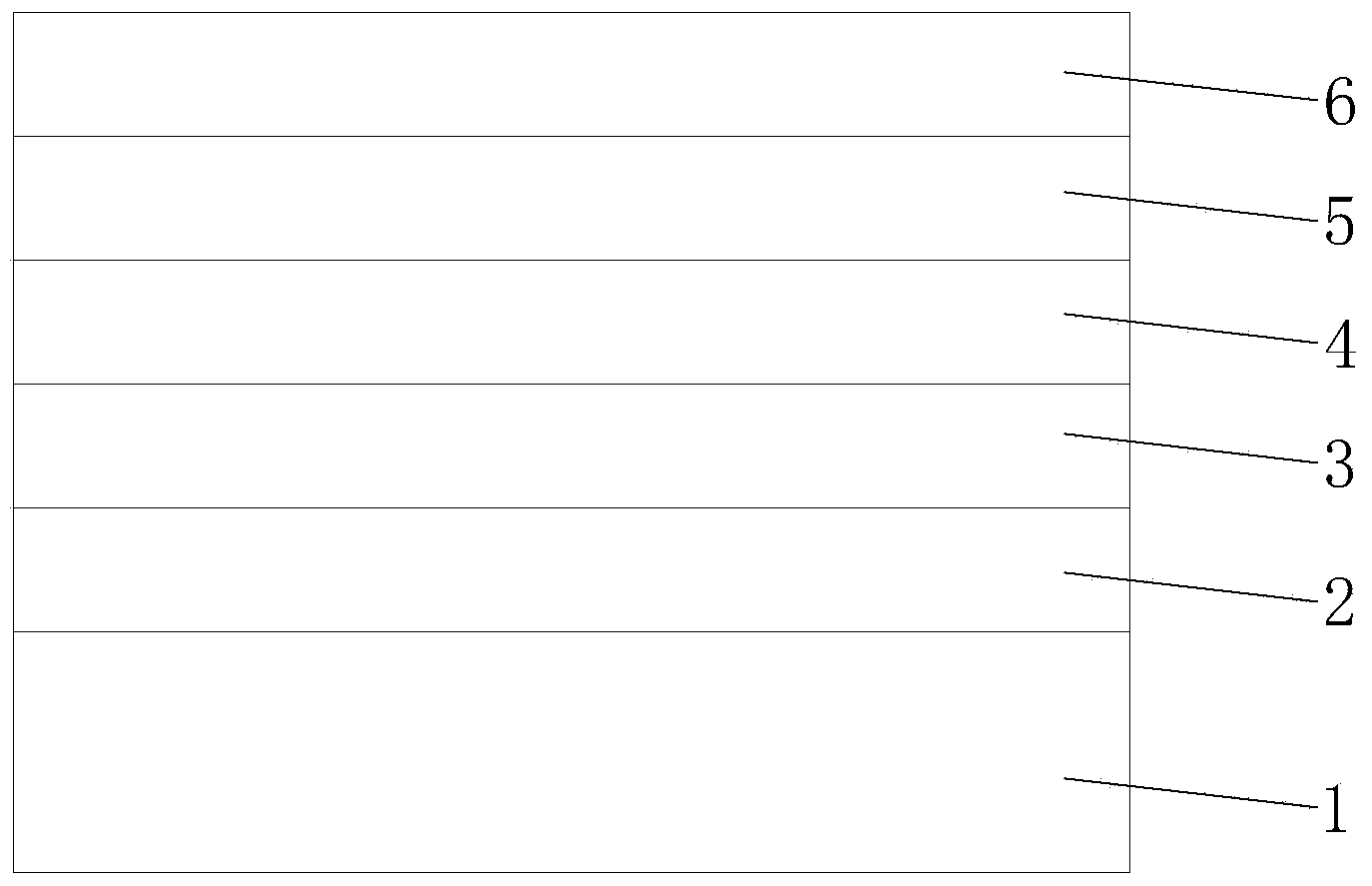

[0015] As shown in the figure, a double-silver LOW-E glass with a simple structure includes a glass substrate 1, and the upper surface of the glass substrate 1 is provided with a bottom ITO dielectric layer 2 and a first Ag layer 3 in sequence from bottom to top. , a middle ITO dielectric layer 4, a second Ag layer 5, and a top ITO dielectric layer 6.

[0016] Further, the thickness of the underlying ITO dielectric layer 2 is 80nm. It adopts magnetron sputtering coating process, sputters indium tin oxide target with intermediate frequency AC power supply, uses argon as sputtering gas, and mixes a small amount of oxygen. Among them, the ratio of argon to oxygen is: (400SCCM~420SCCM):( 20~40SCCM). This layer plays the role of three layers: the bottom dielectric layer, the barrier layer, and the smoothing layer. It can improve the transmittance of the product, protect the Ag layer, and prevent the Ag layer from being corroded, resulting in glass oxidation.

[0017] Still furth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap