Deep-sea mining valve control type clean water pump ore hydraulic lifting equipment

A technology for deep-sea mining and clear water pumps, which is applied in mineral mining, special mining, earthwork drilling, etc., and can solve the difficulties in the deployment and installation of the slurry pump hydraulic lifting system, high reliability requirements, pump lift, efficiency, and cavitation performance Variation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

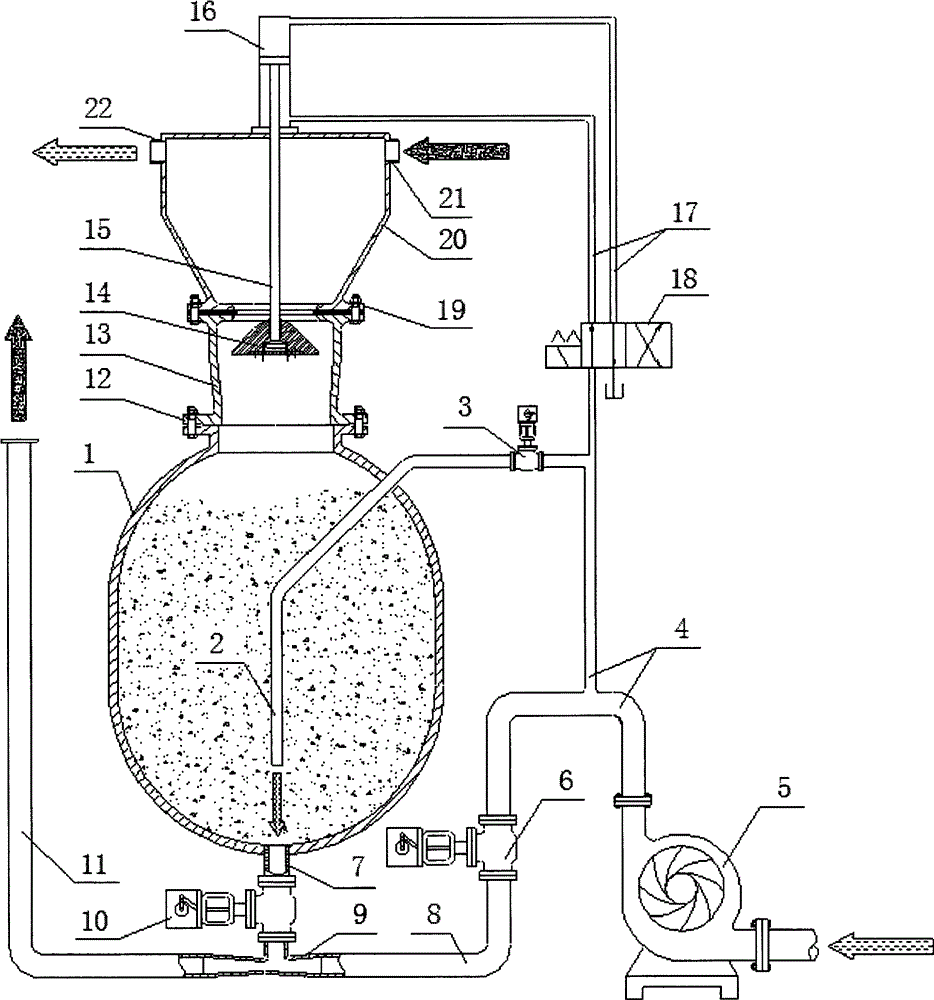

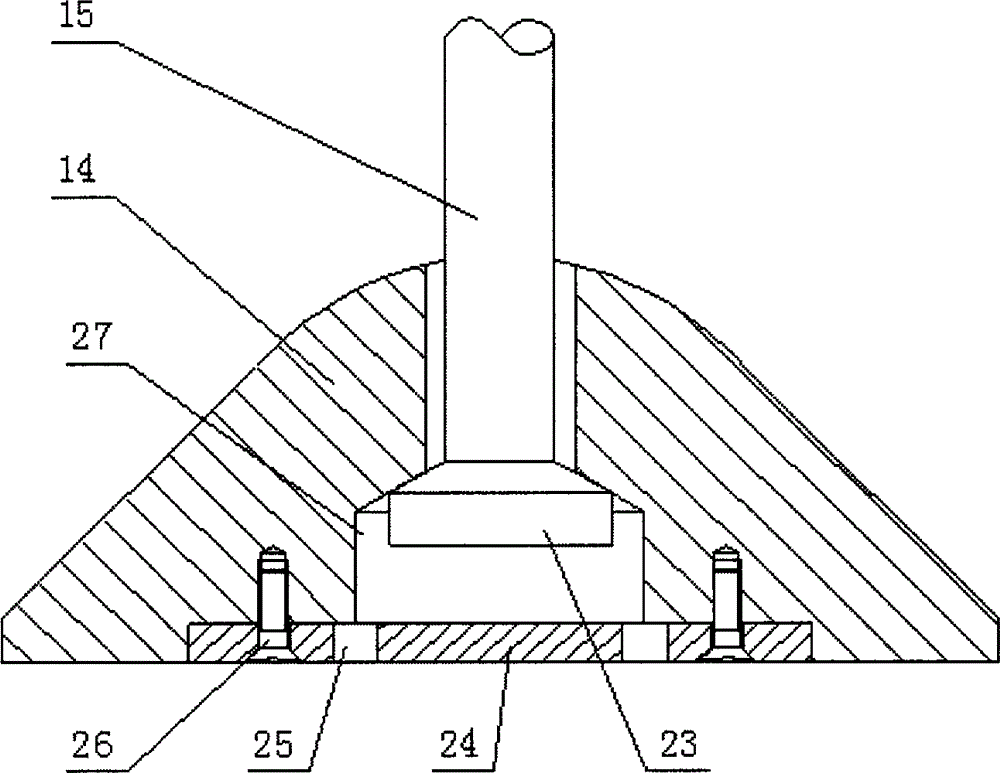

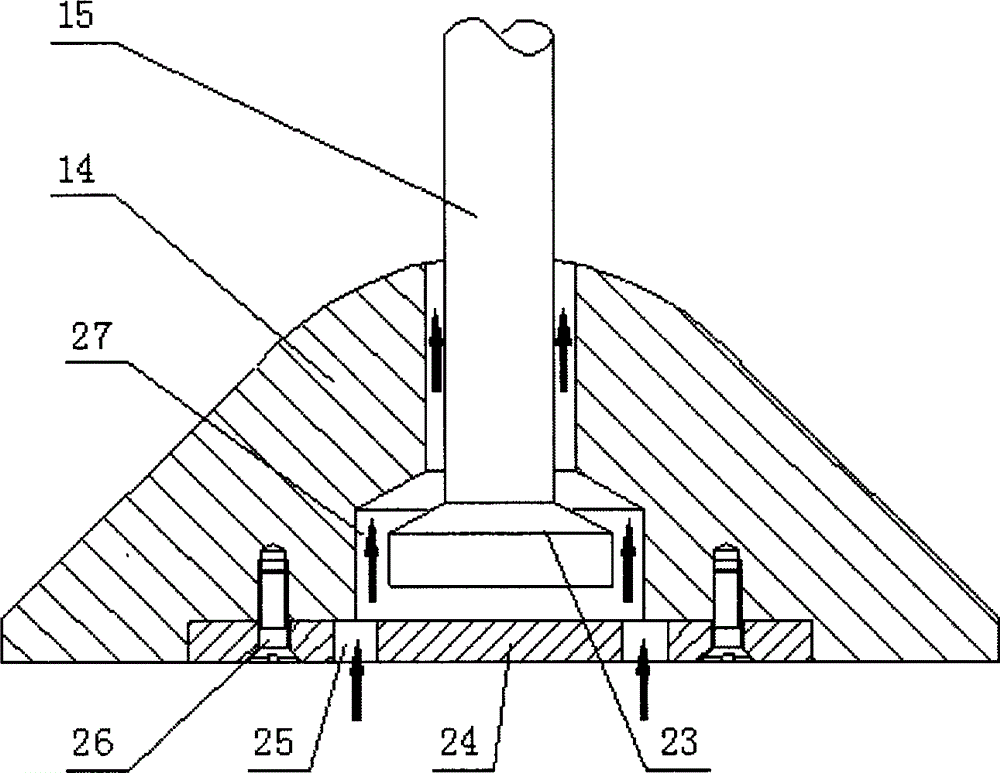

[0022] specific implementation plan

[0023] figure 1 Middle, 1. Storage bin, 2. Injection pipe, 3. Electric valve, 4. Pipeline, 5. Clean water pump, 6. Electric valve, 7. Pipeline, 8. Pipeline, 9. Venturi ejector, 10, Electric valve, 11, pulp lifting pipeline, 12, flange, 13, valve body, 14, piston, 15, piston rod, 16, hydraulic cylinder, 17, pipeline, 18, electromagnetic reversing valve, 19, flange, 20 . Pulp separator, 21. Pulp pipe interface, 22. Water outlet.

[0024] exist figure 1 Among them, the storage bin (1) is provided with an injection pipe (2) connected to the water outlet pipe of the water pump (5) through the electric valve (3) and the pipeline (4), and the upper flange of the storage bin (1) ( 12) A cylindrical bell valve body (13) is installed on the top, and the lower end of the storage bin (1) is connected to the pipeline (7) and the electric valve (10) and placed on the Venturi ejector (9), and the Venturi ejector The right end of device (9) is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com