Method of separating complexing-form DTPA (diethylenetriamine pentaacetic acid) and hardness ions by electrodialysis process

A technology of hardness ions and electrodialysis, applied in separation methods, electrodialysis, and separation of dispersed particles, can solve the problems of difficult industrial application, difficult separation, high cost, etc., achieve good industrial application prospects, simple operation, and reduce waste water discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

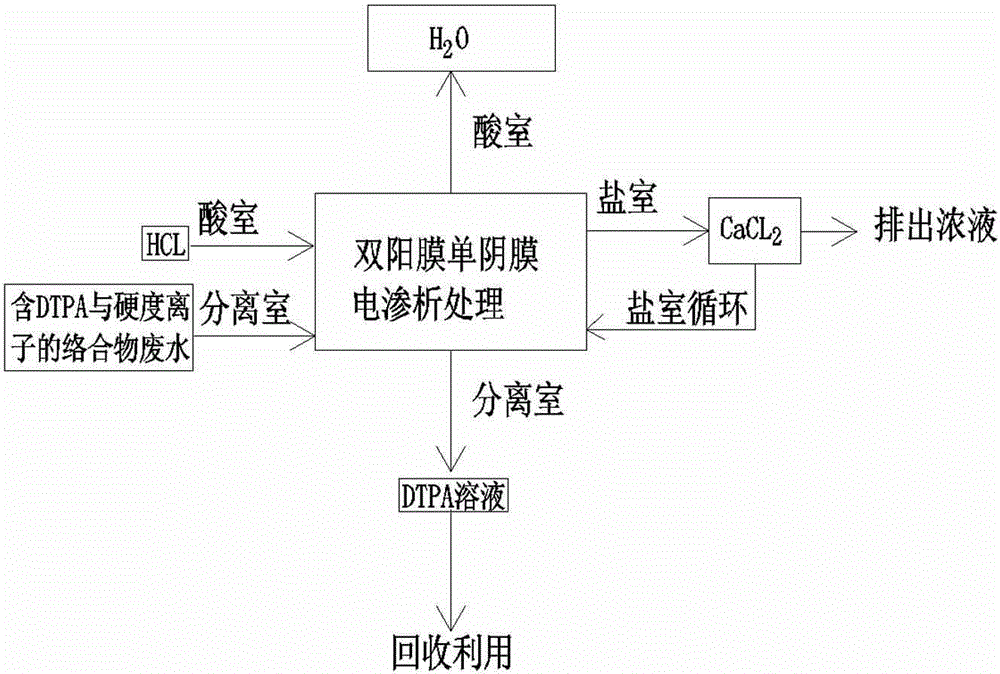

Method used

Image

Examples

Embodiment 1

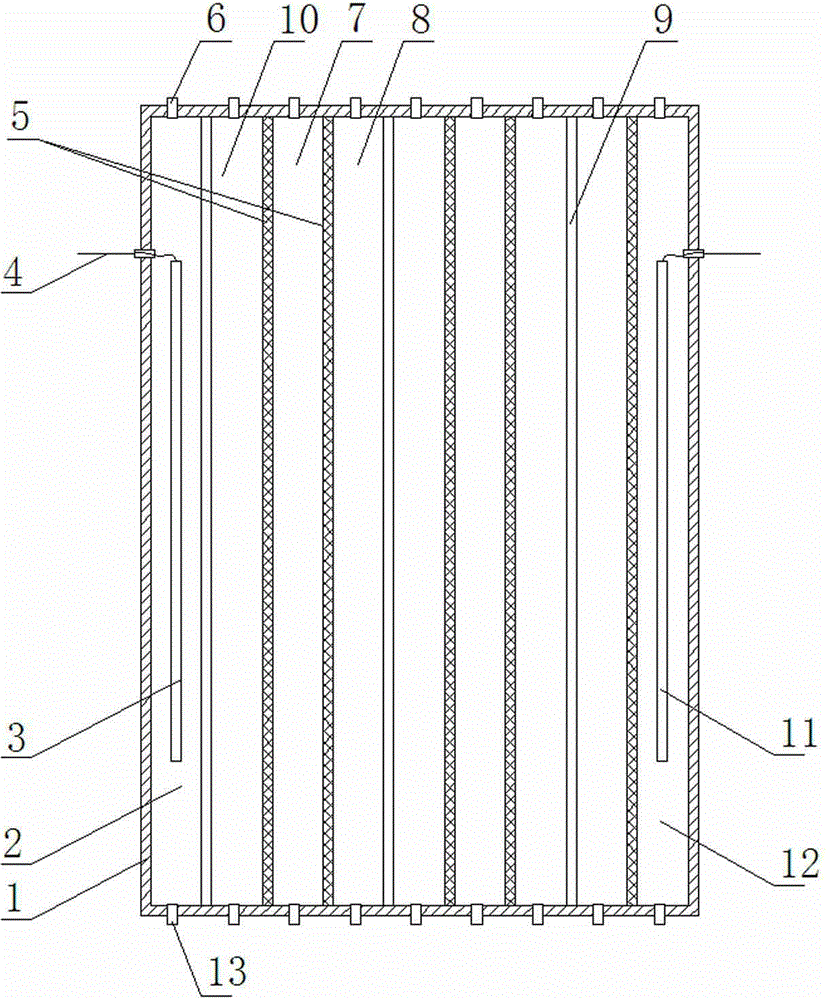

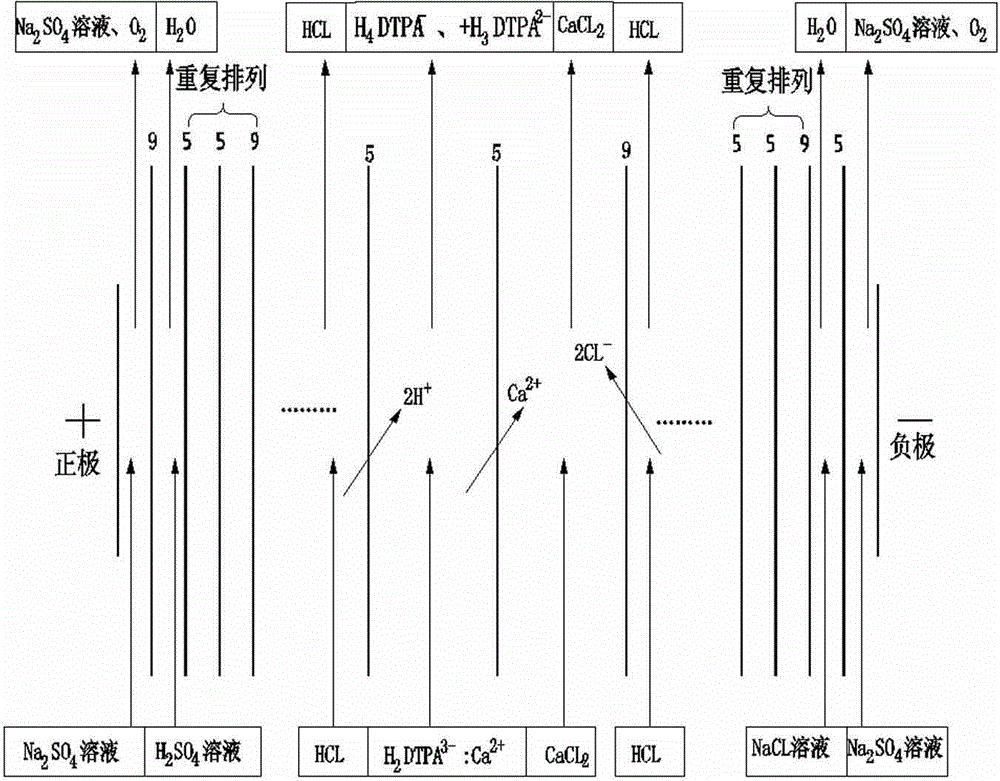

[0022] Adopt the electrodialysis device that two electrodialysis units are installed, fill the Na of 1mol / L in the anode chamber 2 and the cathode chamber 12 of the electrodialysis device 2 SO 4 Solution, the circulating liquid inlet flow rate is 30L / h; the acid chamber 10 of the electrodialysis device is filled with 3-10wt% hydrochloric acid solution, and the acid chamber closest to the anode chamber is filled with 3-10wt% sulfuric acid solution, and the circulating liquid inlet flow rate is 10L / h; fill the salt chamber 8 of the electrodialysis device with 3~5wt% CaCl 2 solution, wherein the salt chamber closest to the cathode chamber is filled with 3-10wt% sodium chloride solution, and the circulating liquid inlet flow rate is 15L / h; Wastewater, the concentration of hardness ions in wastewater is within 500mg / L, the pH value is 7-8, and the flow rate of the circulating liquid is 12L / h; then start the DC power supply, and the current density is 100A / m 2 At this time, the hy...

Embodiment 2

[0024] Adopt the electrodialysis device that six electrodialysis units are installed, fill the Na of 1mol / L in the anode chamber 2 and the cathode chamber 12 of the electrodialysis device 2 SO 4 Solution, the circulating liquid inlet flow rate is 30L / h; the acid chamber 10 of the electrodialysis device is filled with 3-10wt% hydrochloric acid solution, and the acid chamber closest to the anode chamber is filled with 3-10wt% sulfuric acid solution, and the circulating liquid inlet flow rate is 10L / h; fill the salt chamber 8 of the electrodialysis device with 3~5wt% CaCl 2 solution, wherein the salt chamber closest to the cathode chamber is filled with 3-10wt% sodium chloride solution, and the circulating liquid inlet flow rate is 15L / h; Wastewater, the hardness ion concentration of the wastewater is within 500mg / L, the pH value is 7-8, and the flow rate of the circulating liquid is 12L / h; then start the DC power supply, and the current density is 150A / m 2 At this time, the hy...

Embodiment 3

[0026] Adopt the electrodialysis device that ten electrodialysis units are installed, fill the Na of 1mol / L in the anode chamber 2 and the cathode chamber 12 of the electrodialysis device 2 SO 4 Solution, the circulating liquid inlet flow rate is 30L / h; the acid chamber 10 of the electrodialysis device is filled with 3-10wt% hydrochloric acid solution, and the acid chamber closest to the anode chamber is filled with 3-10wt% sulfuric acid solution, and the circulating liquid inlet flow rate is 10L / h; fill the salt chamber 8 of the electrodialysis device with 3~5wt% CaCl 2solution, wherein the salt chamber closest to the cathode chamber is filled with 3-10wt% sodium chloride solution, and the circulating liquid inlet flow rate is 15L / h; Wastewater, the concentration of hardness ions in wastewater is within 500mg / L, the pH value is 7-8, and the flow rate of the circulating liquid is 12L / h; then start the DC power supply, and the current density is 200A / m 2 At this time, the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com