Grinding aid for expanding agent and preparation method of grinding aid

The technology of an expansion agent and a grinding aid is applied in the field of preparation of the grinding aid for the expansion agent, which can solve the problems such as the decrease of concrete strength, and achieve the effects of reducing water consumption, improving grindability, and easily obtaining raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

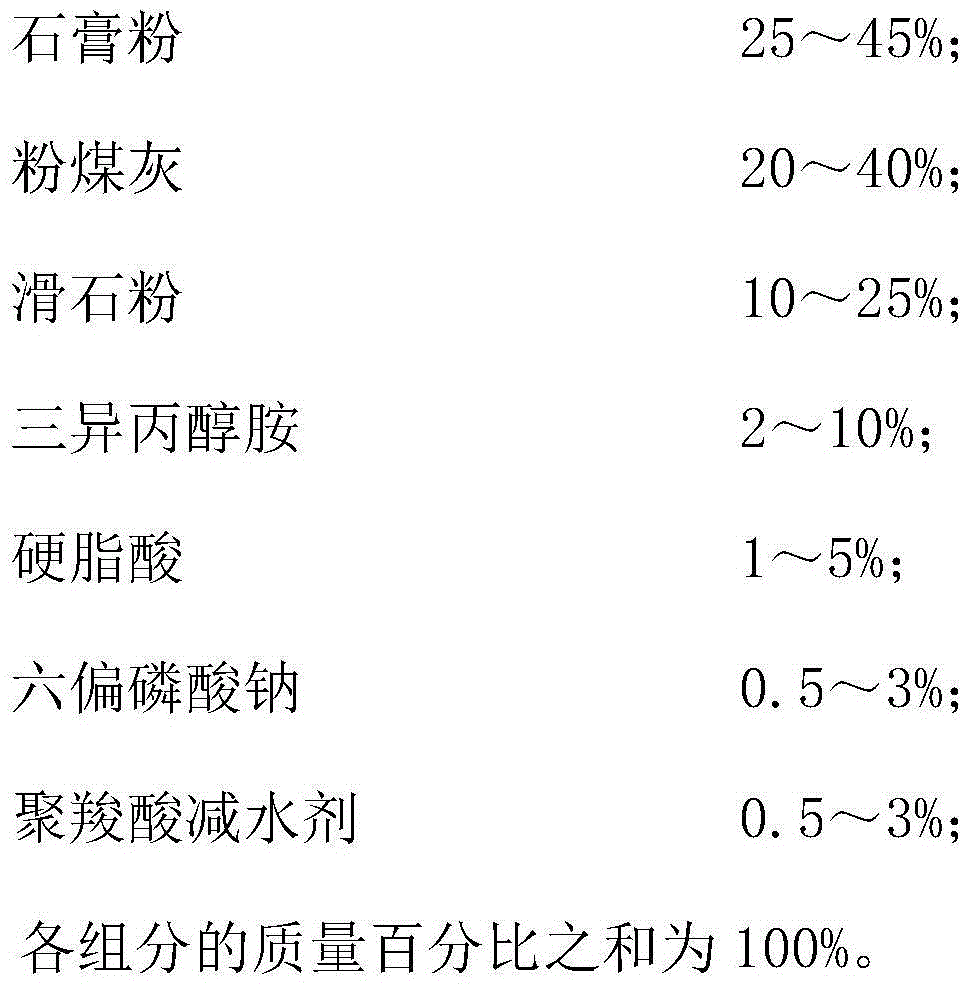

[0037] A kind of grinding aid embodiment 1 for expansion agent of the present invention comprises the following components, and each component is by mass percentage:

[0038]

[0039] The preparation method of the grinding aid for the expansion agent comprises the following steps successively:

[0040] Step 1. Mix triisopropanolamine, stearic acid, and polycarboxylate water reducer according to the ratio of raw materials, and mix and dilute the obtained mixture with absolute ethanol at room temperature at a mass ratio of 8:2 to obtain the pre-prepared mixture solution;

[0041] Step 2, mixing sodium hexametaphosphate, gypsum powder, fly ash, and talcum powder according to the ratio of raw materials and stirring for 10 minutes, and mixing evenly to obtain a mixture;

[0042] Step 3. Continue to stir the mixture in step 2. At the same time, atomize the premix solution obtained in step 1 evenly and spray it on the surface of the mixture in step 2. After drying, the grinding a...

Embodiment 2

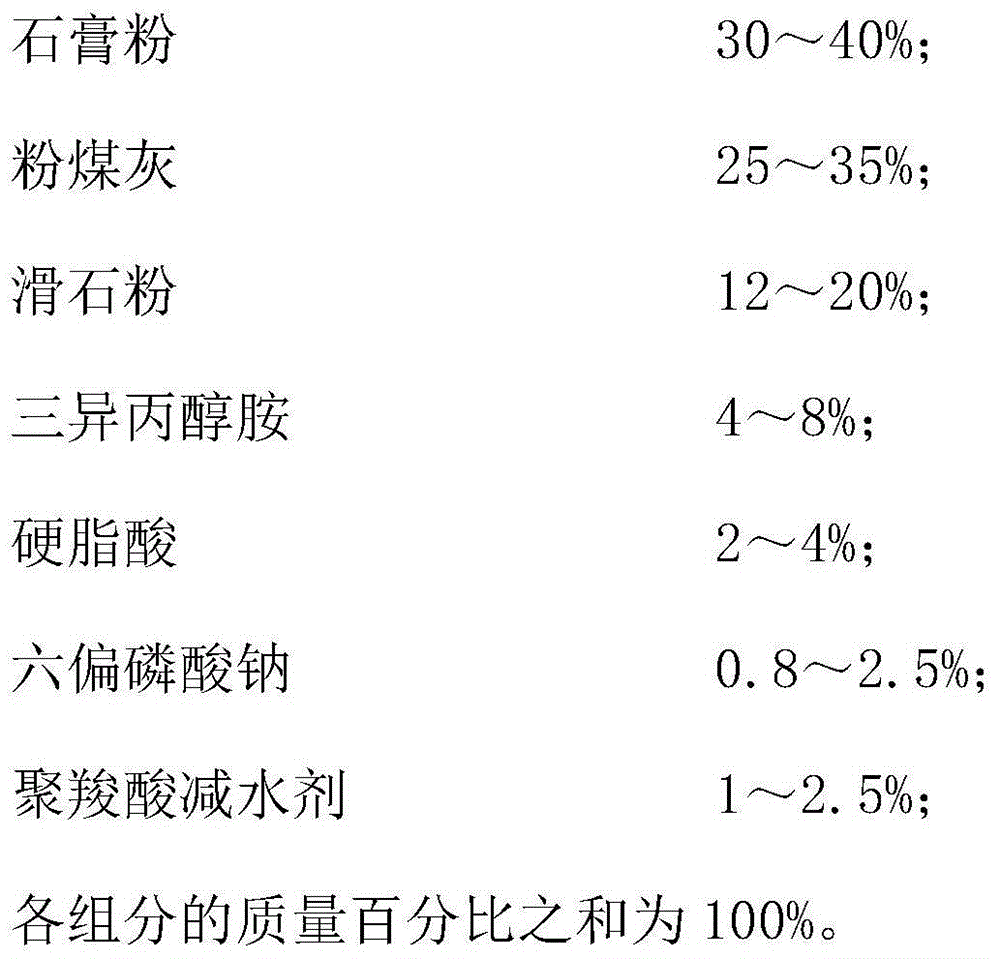

[0043] A kind of grinding aid embodiment 2 for expansion agent of the present invention comprises following components, and each component is by mass percent:

[0044]

[0045] The preparation method of the grinding aid for this expansion agent is the same as in Example 1.

Embodiment 3

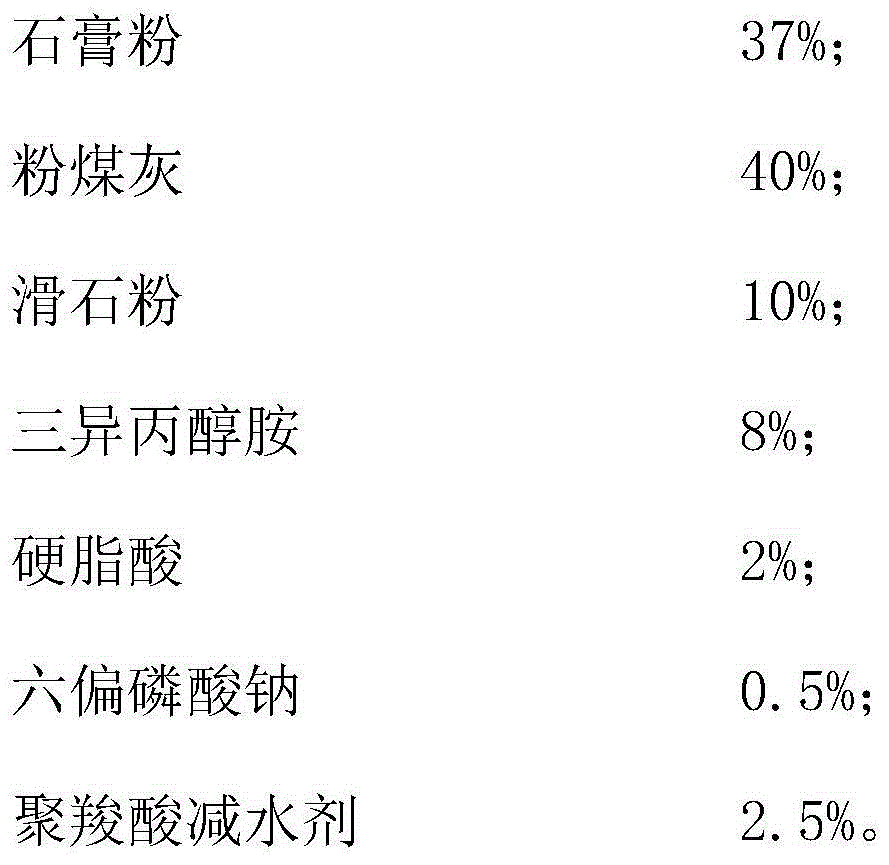

[0046] A kind of grinding aid embodiment 3 for expansion agent of the present invention comprises following components, and each component is by mass percent:

[0047]

[0048]

[0049] The preparation method of the grinding aid for this expansion agent is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com