Degradable magnetic-permeable hot-melt adhesive as well as degradable magnetic-permeable hot-melt adhesive membrane and preparation method of degradable magnetic-permeable hot-melt adhesive membrane

A technology of hot-melt adhesive film and hot-melt adhesive, applied in the direction of film/sheet adhesive, adhesive, epoxy resin glue, etc., can solve the problem that the hot-melt adhesive cannot be biodegraded, and achieve the initial bonding strength. Biodegradable, good compatibility, high initial bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Correspondingly, an embodiment of the present invention provides a method for preparing the above-mentioned degradable magnetically conductive hot-melt adhesive film, the method comprising the following steps:

[0047] The above-mentioned degradable magnetically conductive hot-melt adhesive solution is coated to form a film, and then dried.

[0048] Wherein, in one embodiment, the coating and film formation can be performed on an adhesive coating production line. After the degradable magnetically conductive hot-melt adhesive is coated on the release paper surface on the adhesive coating production line, the degradable magnetically conductive hot-melt adhesive can be evenly dispersed without generating bubbles and has a smooth surface.

[0049] In another embodiment, the coating speed of the coating film is 50-150 m / min, and in a specific embodiment, the coating speed is 100 m / min. The thickness and flatness of the degradable magnetically conductive hot-melt adhesive fi...

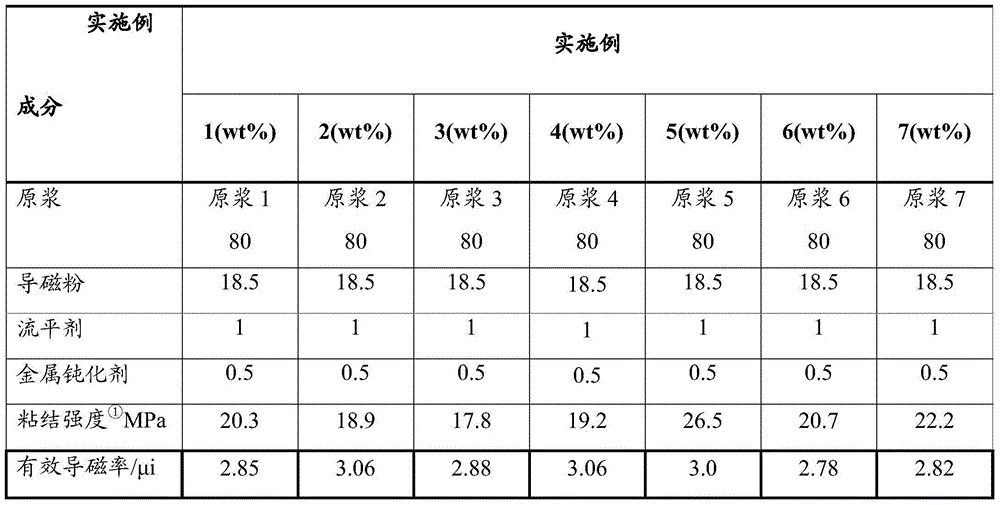

Embodiment 1-7

[0054] Embodiments 1-7 provide a degradable magnetically conductive hot-melt adhesive and a degradable magnetically conductive hot-melt adhesive film prepared from the degradable magnetically conductive hot-melt adhesive. Among them, the components contained in the degradable magnetically conductive hot melt adhesive and the content of each component are shown in Table 1 below.

[0055] The preparation method of the present embodiment 1-7 degradable magnetic conduction hot melt adhesive:

[0056] First, according to the original rubber composition in Table 2, put each component into the toluene / acetone mixed solvent according to the proportion, stir in a closed low speed, heat to 60°C, dissolve for 2 hours until the glue is uniform, and then make the original rubber;

[0057] According to the composition of the degradable magnetically conductive hot melt adhesive in Table 1, the original rubber and other components will be uniformly stirred in a medium-speed stirrer according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com