Fagopyrum tararicum vinegar and making method thereof

The technology of tartary buckwheat vinegar and tartary buckwheat is applied in the field of food processing, which can solve the problems of chemical reagent residue, waste of nutrients, complicated process, etc., and achieve the effects of reducing triglyceride, high content of nutrients and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

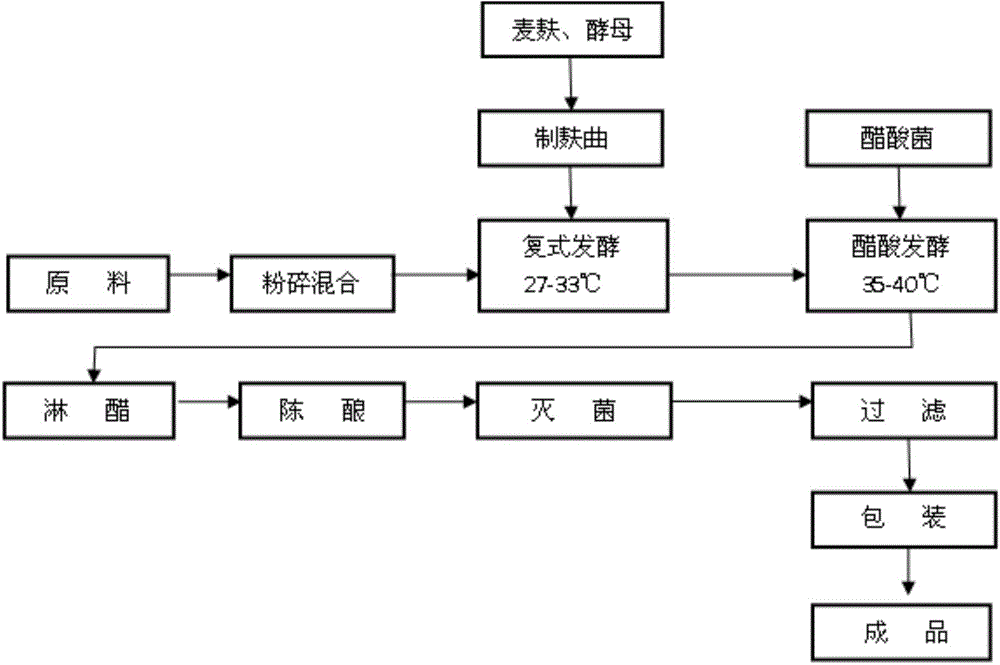

[0047] The preparation of tartary buckwheat vinegar, the specific preparation method refers to the attached figure 1 .

[0048] (1) Crushing of raw materials: choose high-quality buckwheat and corn, crush and set aside.

[0049] (2) Bran koji preparation: add yeast with 4% of the wheat bran mass into the wheat bran, cultivate it at 28°C to 30°C until it turns white or off-white (40 hours), and blow it with a fan to obtain the bran koji, which is ready for use.

[0050] (3) Double fermentation

[0051] Weigh 150kg of buckwheat, 300kg of corn, 225kg of bran koji, 540kg of bran, 0.45kg of Angel wine koji, and 2000kg of water, pour them into the production tank, stir evenly, and perform compound fermentation. The wine mash is fermented for 1-2 days, at least 2 times a day, and the product temperature is controlled at 27-33 ° C. After ten days of fermentation, samples are taken to measure the acidity and alcohol content. The alcohol content is 4.5%, and the acidity content is 1.2...

Embodiment 2

[0062] The preparation of tartary buckwheat vinegar, the specific preparation method refers to the attached figure 1 .

[0063] (1) Crushing of raw materials: choose high-quality buckwheat and corn, crush and set aside.

[0064] (2) Bran koji: add yeast with 3% of the wheat bran mass into the wheat bran, cultivate it at 28°C to 30°C until it turns white or off-white (40 hours), and blow it with a fan to obtain the bran koji, which is ready for use.

[0065] (3) Double fermentation

[0066] Weigh 150kg of buckwheat, 250kg of corn, 180kg of bran koji, 450kg of bran, 0.38kg of Angel wine koji, and 1750kg of water, pour them into the production tank, stir evenly, and perform compound fermentation. The wine mash is fermented for 1-2 days, at least 2 times a day, and the product temperature is controlled at 27-33 ° C. After ten days of fermentation, samples are taken to measure the acidity and alcohol content. The alcohol content is 4.4%, and the acidity content is 1.5%. Double fe...

Embodiment 3

[0077] The preparation of tartary buckwheat vinegar, the specific preparation method refers to the attached figure 1 .

[0078] (1) Crushing of raw materials: choose high-quality buckwheat and corn, crush and set aside.

[0079] (2) Bran koji: add yeast with 5% of the wheat bran mass into the wheat bran, cultivate it at 28°C to 30°C until it turns white or off-white (40 hours), and blow it with a fan to obtain the bran koji, which is ready for use.

[0080] (3) Double fermentation

[0081] Weigh 150kg of buckwheat, 360kg of corn, 240kg of bran koji, 600kg of bran, 0.6kg of Angel wine koji, and 2400kg of water, pour them into the production pool, stir evenly, and perform double fermentation. The wine mash is fermented for 1-2 days, at least 2 times a day, and the product temperature is controlled at 27-33 ° C. After ten days of fermentation, samples are taken to measure the acidity and alcohol content. The alcohol content is 4.8%, and the acidity content is 1.7%. Double ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com