A method for improving the wear resistance of automobile glass concave mold

A technology of automotive glass and wear resistance, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of easy wear on both sides of the mold, mold traces on the glass edge, and lower customer satisfaction, etc. , to achieve the effect of improving the appearance quality of the glass, keeping the surface smooth and even, and the appearance quality of the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

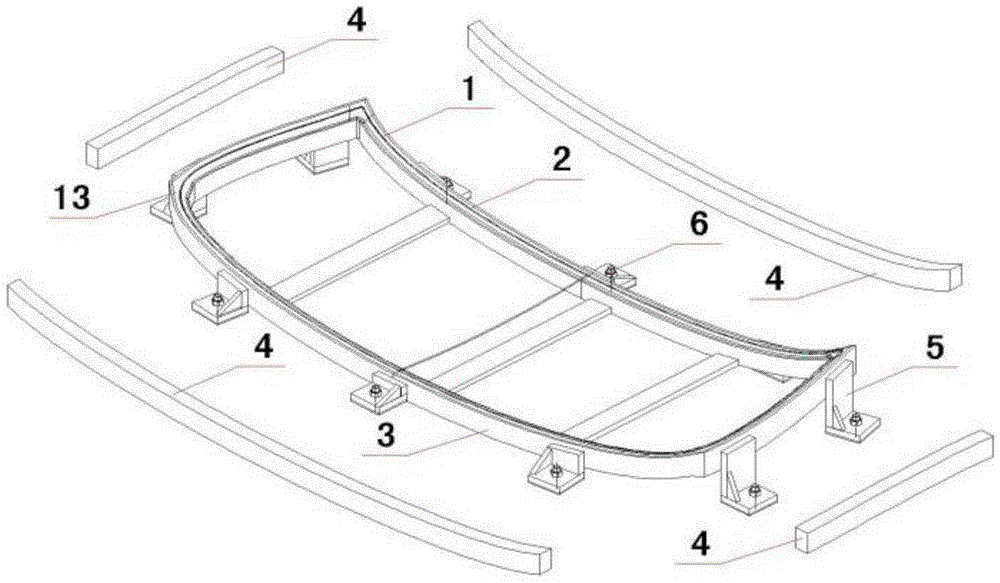

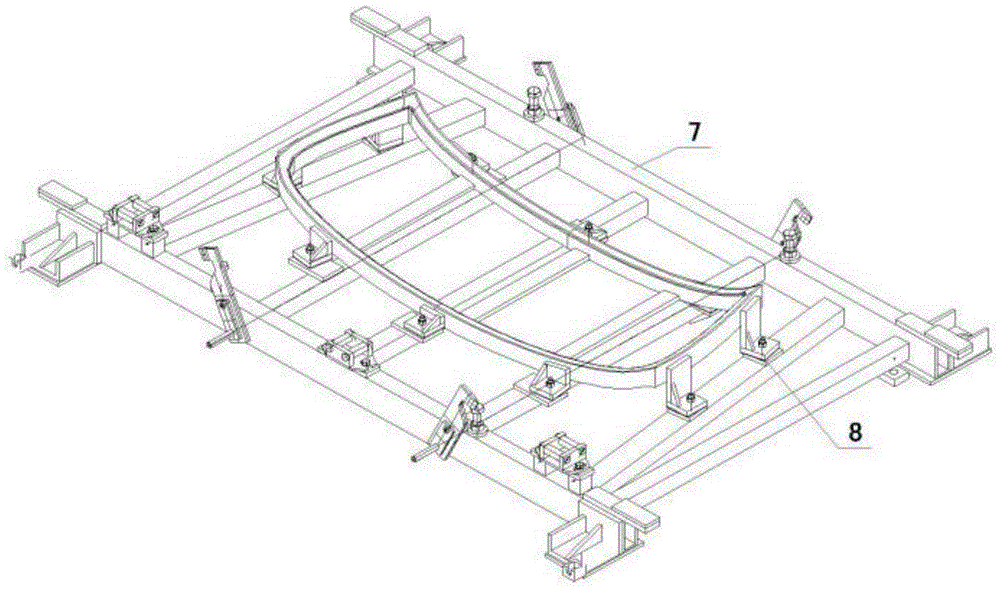

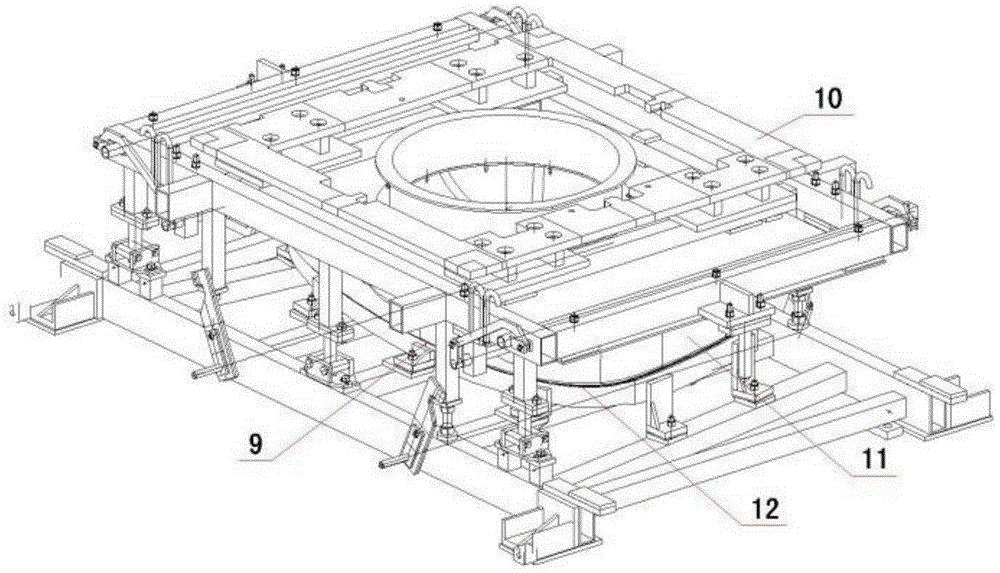

[0021] Such as Figure 1~3 As shown, the automobile glass concave mold includes a concave mold surface 2 matched with the shape of the formed automobile glass, a concave mold body 3 arranged below the concave mold surface 2, a concave mold blank 4 arranged around the concave mold body 3, and the concave mold body 3 passes through The die support foot 5 and the bolt 6 arranged below it are fixed on the die support assembly 7, and a gasket 8 is set between the die support foot 5 and the die support assembly 7, and the punch 11 is arranged on the die support assembly 7. On, the punch 11 is fixed on the punch assembly 10 . Match the two reference holes 9 with the punch assembly 10, and check the gap between the concave mold surface 2 and the punch 11 to keep a reasonable value; , stainless steel pads 8 of different thicknesses on the pad. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com