A kind of copper and copper alloy environment-friendly pickling agent, copper and copper alloy silver plating pretreatment method

A technology of copper alloy and pickling agent, applied in the field of copper and copper alloy environmental protection pickling agent, copper and copper alloy silver plating pretreatment field, can solve the problems of acid solution environmental pollution, poor cleaning effect, etc., and achieve high cleaning quality , protect the health of employees, and ensure the effect of environmental protection and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

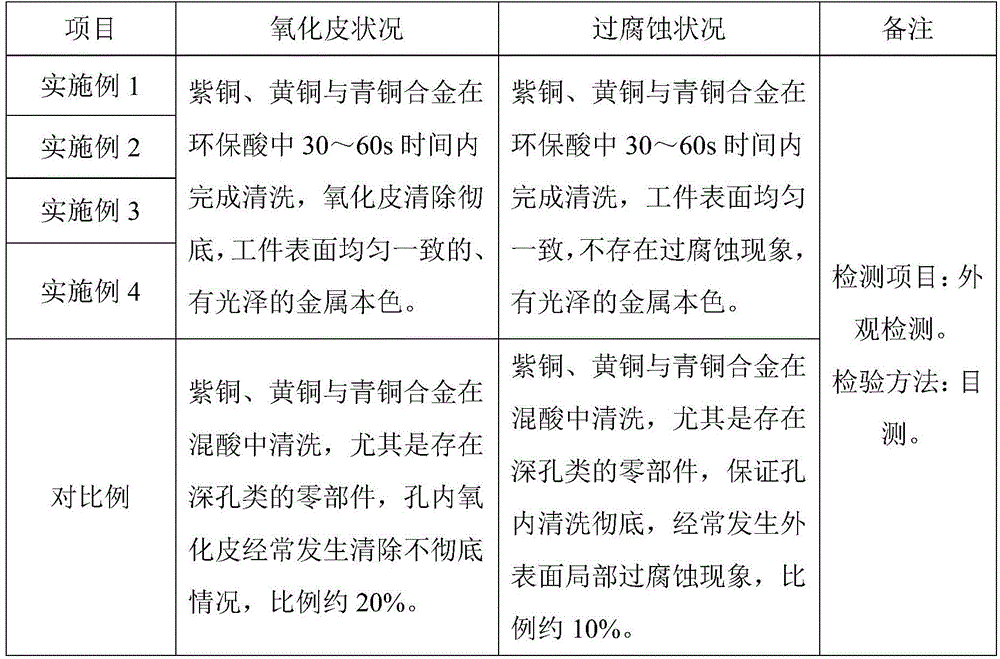

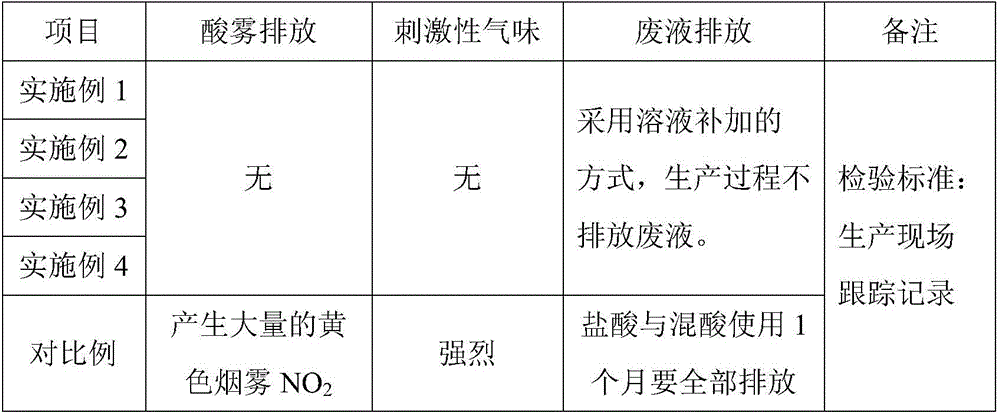

Examples

Embodiment 1

[0026] The copper and copper alloy environment-friendly pickling agent of the present embodiment comprises the component of following mass percent: mass concentration is 98% sulfuric acid 21.5%, phytic acid (cyclohexyl hexaphosphate) 15.5%, sodium nitrate 10%, Dispersant 1.0%, balance is water.

[0027] Wherein, the dispersant comprises the following components by mass percentage: sodium lauryl sulfate 30%, potassium monododecyl phosphate 30%, carboxyethyl thiosuccinic acid 20%, polyethylene glycol 20020 %.

[0028] The copper and copper alloy silver plating pretreatment method of the present embodiment may further comprise the steps:

[0029] 1) Degreasing treatment: Take the copper parts, soak them in a degreasing agent at 70°C for 3 minutes and take them out; the degreasing agent includes the following components: NaOH 8g / L, NaOH 2 CO 3 60g / L, Na 3 PO 4 12H 2 O 54g / L, Na 2 SiO 3 7g / L, the balance is water;

[0030] 2) One-time water washing: at room temperature, wa...

Embodiment 2

[0035] The copper and copper alloy environment-friendly pickling agent of the present embodiment comprises the component of following mass percent: mass concentration is the sulfuric acid 29.0% of 98%, phytic acid (cyclohexyl hexaphosphate) 10.5%, sodium nitrate 2.5%, Dispersant 2.0%, balance is water.

[0036] Wherein, the dispersant comprises the following components by mass percentage: sodium lauryl sulfate 30%, potassium monododecyl phosphate 30%, carboxyethyl thiosuccinic acid 20%, polyethylene glycol 20020 %.

[0037] The copper and copper alloy silver plating pretreatment method of the present embodiment may further comprise the steps:

[0038] 1) Degreasing treatment: Take the brass parts, soak them in a degreasing agent at 60°C for 5 minutes and take them out; the degreasing agent includes the following components: NaOH 9g / L, NaOH 2 CO 3 57g / L, Na 3 PO 4 12H 2 O 50g / L, Na 2 SiO 3 10g / L, the balance is water;

[0039]2) One-time water washing: at room temperat...

Embodiment 3

[0044] The copper and copper alloy environment-friendly pickling agent of the present embodiment comprises the component of following mass percent: mass concentration is 98% sulfuric acid 36%, phytic acid (cyclohexyl hexaphosphate) 5%, sodium nitrate 7.5%, Dispersant 0.5%, the balance is water.

[0045] Wherein, the dispersant comprises the following components by mass percentage: sodium lauryl sulfate 30%, potassium monododecyl phosphate 30%, carboxyethyl thiosuccinic acid 20%, polyethylene glycol 20020 %.

[0046] The copper and copper alloy silver plating pretreatment method of the present embodiment may further comprise the steps:

[0047] 1) Degreasing treatment: take the bronze parts, soak them in a degreasing agent at 65°C for 4 minutes, and then take them out; the degreasing agent includes the following components: NaOH 10g / L, NaOH 2 CO 3 53g / L, Na 3 PO 4 12H 2 O 60g / L, Na 2 SiO 3 5g / L, the balance is water;

[0048] 2) One-time water washing: at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com