Small-caliber combined rib bottom pile rapid protection technology for super-large high-position mud-rock flow

A small diameter, debris flow technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of high time cost, unfavorable emergency treatment of debris flow, etc., and achieve the effect of preventing debris flow, clear treatment procedures, and reducing possibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

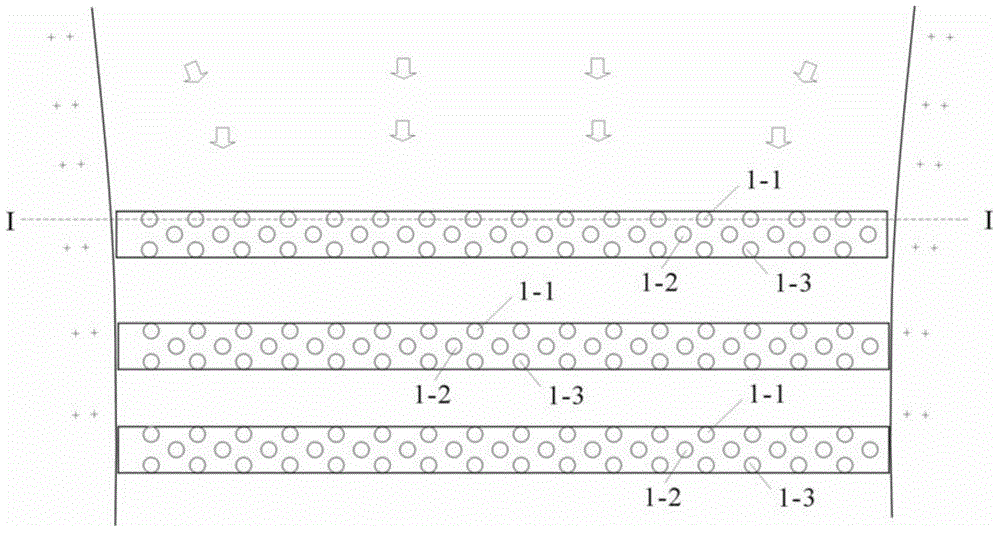

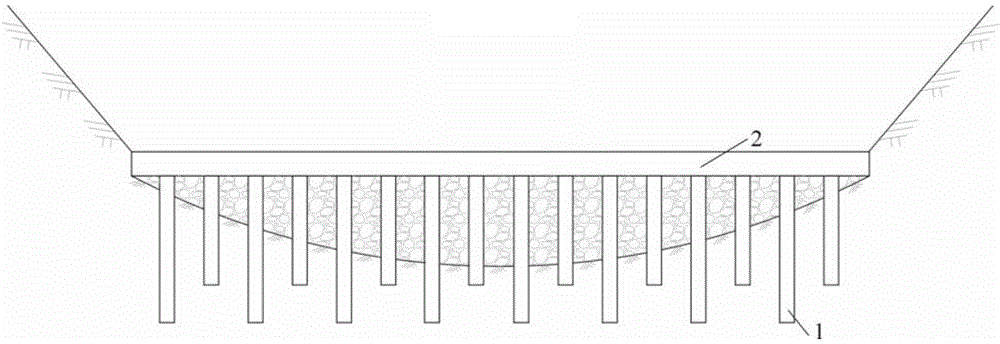

[0026] Example 1: Conditions in the construction area: a large number of geological disasters such as collapses and landslides developed on both sides of the ditch. The total amount of solid material sources is estimated to be less than 4 million cubic meters, and the dynamic reserves are 1.4 million cubic meters. The reserves are 6.8 million square meters. The damming bodies and breaches formed in the debris flow have the characteristics of strong erosion and high mud level. In order to prevent further debris flow outbreaks in the main and branch ditches in this area, more solid matter sources will be rushed out, forming a disaster-causing blocking debris flow, the specific construction steps are as follows. The first step: level measurement and positioning. Level the site, measure and set out the lines according to the pile position, spacing and elevation required by the design and construction; the second step: construct 3 small-diameter pile groups, and the first, second ...

Embodiment 2

[0027] Example 2: Conditions of the construction area: the local terrain of the debris flow ditch is relatively open and gentle, the slope is less than 10°, the water flow is slow, the water volume is small, and the flow rate is 50m 3 / s below. In this case, 2 small-diameter pile groups will be constructed after leveling the site at the mouth of the ditch, and a total of 300 prefabricated small-diameter piles in 2 rows and 3 rows will be laid at the 50m-long ditch. The rows of small-diameter piles are arranged in the shape of "pin". The pile diameter is 200mm, the center distance between two adjacent rows of piles is 200mm, and the center distance between the same row of small-diameter piles is 600mm. The piles of the same row in the first column on the facing surface are of different lengths, and the long and short piles are arranged at intervals in sequence. The long piles are 5m, the short piles are 3m, and the second piles are all 3m short piles. Cast rib beams on site, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com