Electrochemical sensor for rapidly measuring carmine and citrine and preparing method thereof

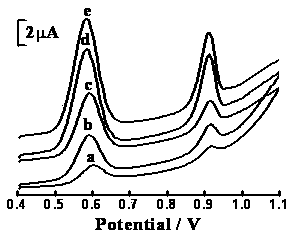

A rapid determination, carmine technology, applied in the direction of material electrochemical variables, etc., to achieve high sensitivity, high sensitivity determination, to meet the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] S1. Preparation of alumina material: Al(NO 3 ) 3 9H 2 O was dissolved in secondary water, then urea was added, the molar ratio of Al, urea, and water was 1:9:90, and then the obtained solution was transferred to a hydrothermal reaction kettle, and reacted in an oven at 100°C for 6 hours, and the solid obtained from the reaction was , washed with secondary water, suction filtered, dried in an oven at 80°C for 24 hours, and then put into a muffle furnace for calcination at 500°C for 2 hours to obtain an alumina material;

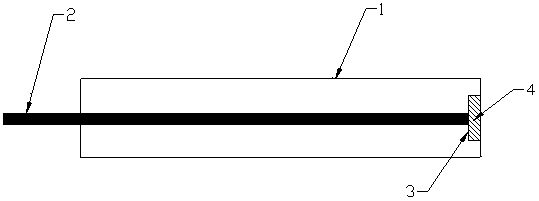

[0031] S2. Preparation of the sensor: Mix 0.1g of alumina material, 0.9g of graphite powder and 0.3mL of paraffin oil evenly to obtain a carbon paste, then press the carbon paste into the front cavity of the sensor housing, and finally grind and polish it on weighing paper , to prepare an electrochemical sensor for rapid determination of carmine and tartrazine.

Embodiment 2

[0033] S1. Preparation of alumina material: Al(NO 3 ) 3 9H 2 O was dissolved in secondary water, then urea was added, the molar ratio of Al, urea, and water was 1:9:90, and then the obtained solution was transferred to a hydrothermal reaction kettle, and reacted in an oven at 100°C for 9 hours, and the solid obtained from the reaction was , washed with secondary water, suction filtered, dried in an oven at 80°C for 24 hours, and then put into a muffle furnace for calcination at 500°C for 2 hours to obtain an alumina material;

[0034] S2. Preparation of the sensor: Mix 0.1g of alumina material, 0.9g of graphite powder and 0.3mL of paraffin oil evenly to obtain a carbon paste, then press the carbon paste into the front cavity of the sensor housing, and finally grind and polish it on weighing paper , to prepare an electrochemical sensor for rapid determination of carmine and tartrazine.

Embodiment 3

[0036] S1. Preparation of alumina material: Al(NO 3 ) 3 9H 2 O was dissolved in secondary water, then urea was added, the molar ratio of Al, urea, and water was 1:9:90, and then the obtained solution was transferred to a hydrothermal reaction kettle, and reacted in an oven at 100°C for 12 hours, and the solid obtained from the reaction was , washed with secondary water, suction filtered, dried in an oven at 80°C for 24 hours, and then put into a muffle furnace for calcination at 500°C for 2 hours to obtain an alumina material;

[0037] S2. Preparation of the sensor: Mix 0.1g of alumina material, 0.9g of graphite powder and 0.3mL of paraffin oil evenly to obtain a carbon paste, then press the carbon paste into the front cavity of the sensor housing, and finally grind and polish it on weighing paper , to prepare an electrochemical sensor for rapid determination of carmine and tartrazine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com