Alignment layer detection machine

An alignment film and testing machine technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the process, unable to meet the needs of alignment film testing, low reliability of testing results, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

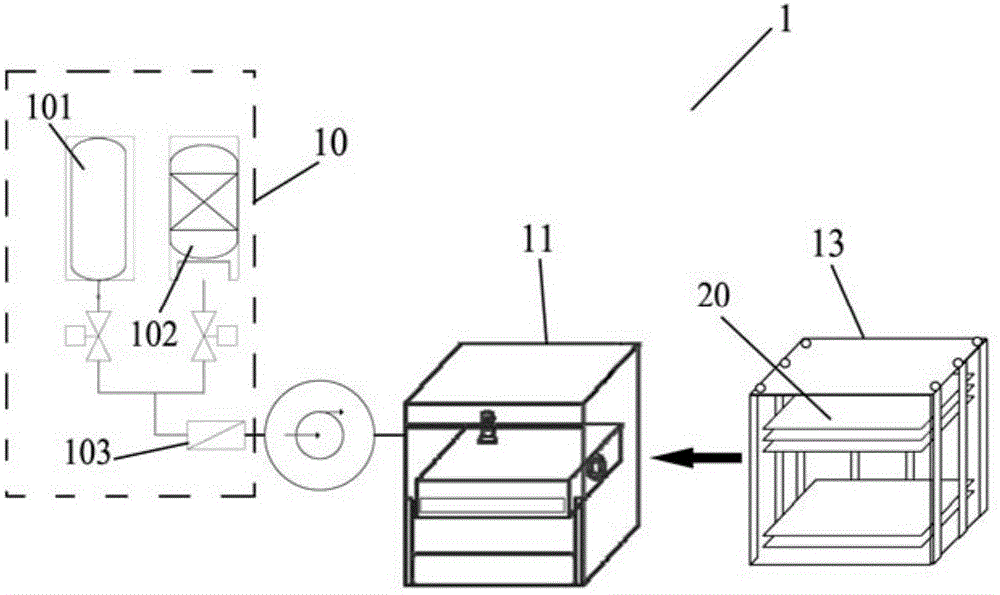

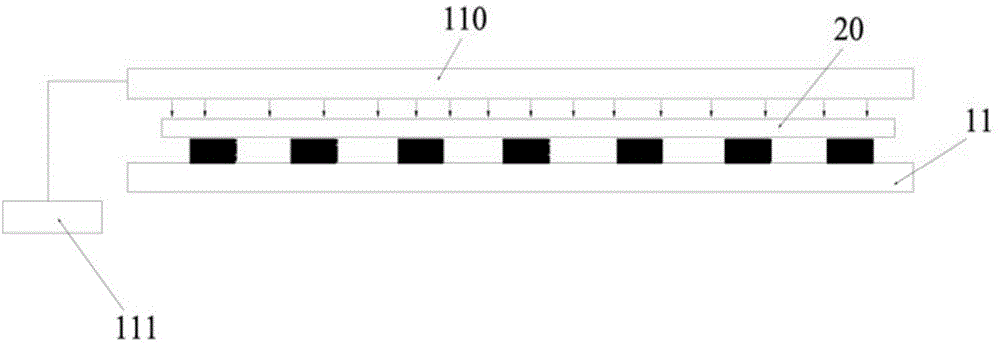

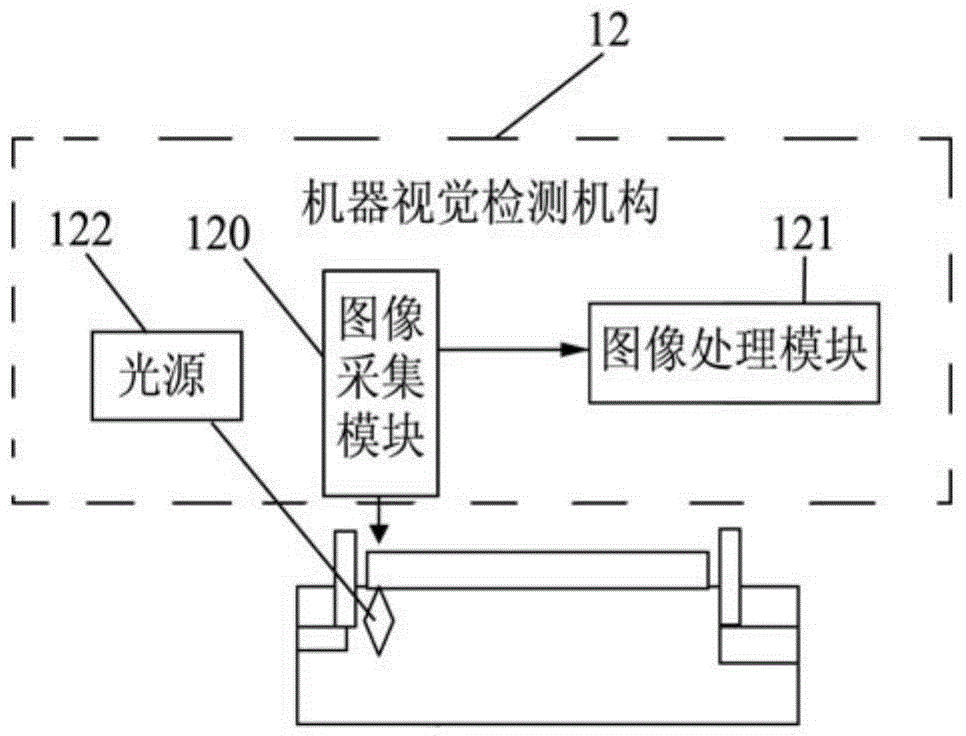

[0052] Combining the above-mentioned first and second embodiments, in the alignment film detector 1 provided by the present invention, the steam is first input into the chamber 11 and diffused in the chamber 11. During the diffusion process, the steam adheres to the substrate 20 and the surface of the alignment film to form water drop particles; because the diffusion of steam in the chamber 11 will eventually make it roughly uniformly distributed in each area of the chamber 11, the thickness of the water drop particles on the substrate 20 and the surface of the alignment film The uniformity of the alignment film is better; thus the alignment film inspection machine 1 provided by the present invention can adopt the machine vision inspection mechanism 12 to collect images, and according to the collected images, automatically detect whether there is a defect in the groove on the alignment film, and the position where the defect exists, Compared with the manual detection in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com