No-backwall type solar greenhouse

A technology of solar greenhouse without rear wall, applied in the field of solar greenhouse, can solve the problems of inability to plant vegetables that love high temperature in winter, poor heat storage and heat preservation performance, etc., and achieve the effects of long service life, improved protection performance, and good weed control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

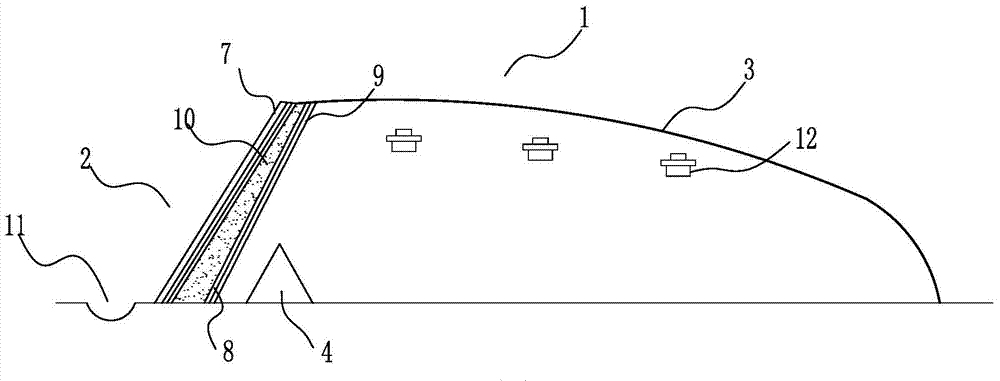

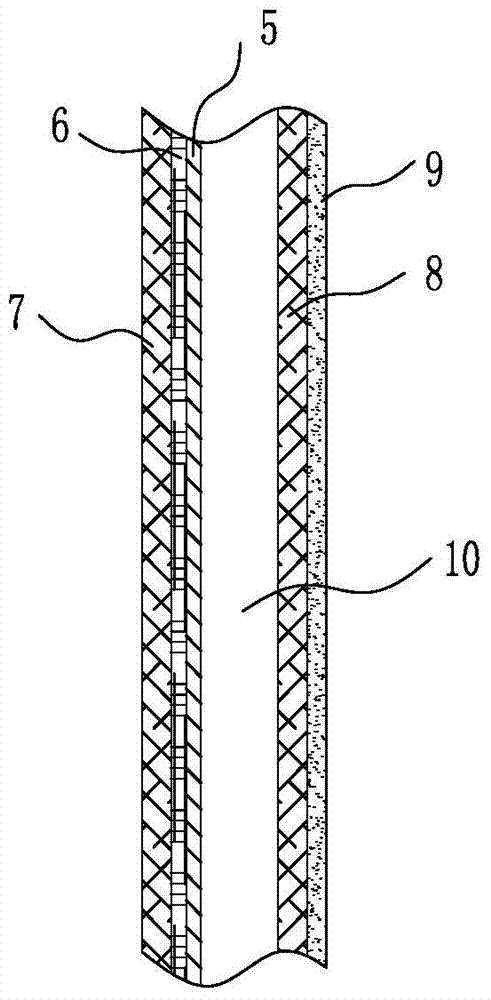

[0010] Such as figure 1 with figure 2 As shown, a back-wall type solar greenhouse includes a shed body 1. The shed body includes a rear slope surface insulation body 2 and a front slope surface light-transmitting insulation body 3, and the shed body 1 is provided with a heat storage soil pile 4 for storage Hot soil pile 4 has a heat storage function: it absorbs heat during the day and releases heat at night to maintain the normal growth temperature of vegetables at night. The back slope surface insulation body 2 includes a back slope surface body 10, the outer surface of the back slope surface body 10 is covered with a waterproof plastic film 5, and the waterproof plastic film 5 is covered with a non-woven fabric 6. The surface of the cloth 6 is poured with an outer protective slurry 7 formed by mixing glue and mud. The outer protective slurry can also be micro-filled. The micro-filled method can make the outer protective slurry solidify slowly, making the outer protective Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com