Composite reverse osmosis scale inhibitor for reverse osmosis membrane

A technology of reverse osmosis membrane and scale inhibitor, applied in the field of compound reverse osmosis scale inhibitor, which can solve problems such as environmental hazards and water eutrophication, and achieve excellent scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0015] Based on the total weight of the antiscalant, mix and stir 20% polyepoxysuccinate sodium PESA, 10% 2-phospho-1,2,4-tricarboxylic acid butane PBTCA, 2% hydroxyethylene diphosphonic acid HEDP , 10% polyacrylic acid PAA and the remaining deionized water to prepare the composite reverse osmosis scale inhibitor XY-ANGO A20 for reverse osmosis membrane of the present invention, referred to as A20.

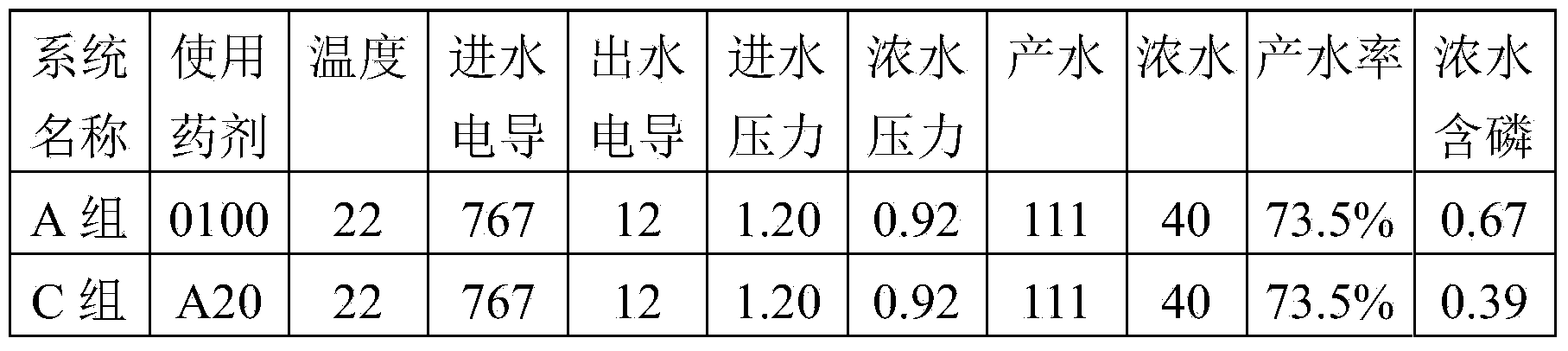

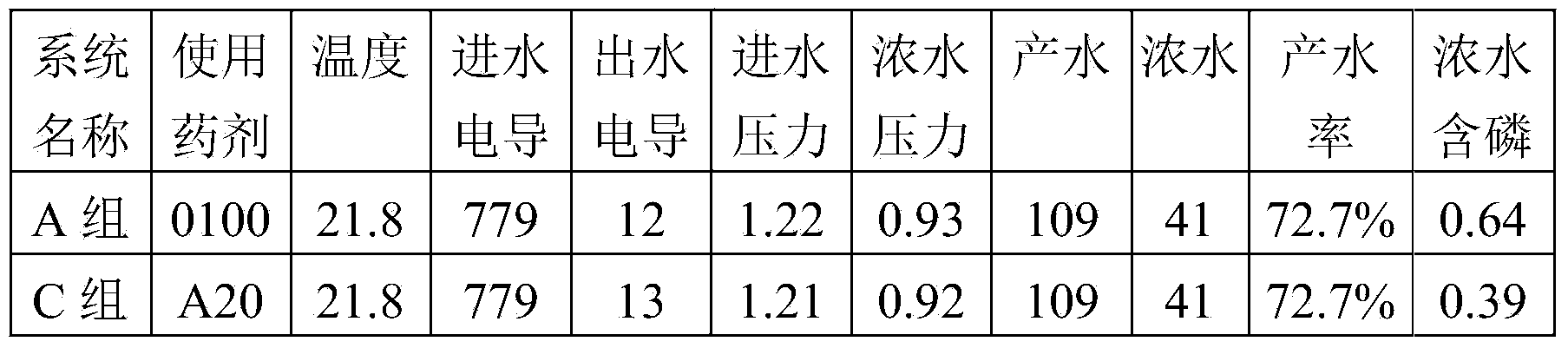

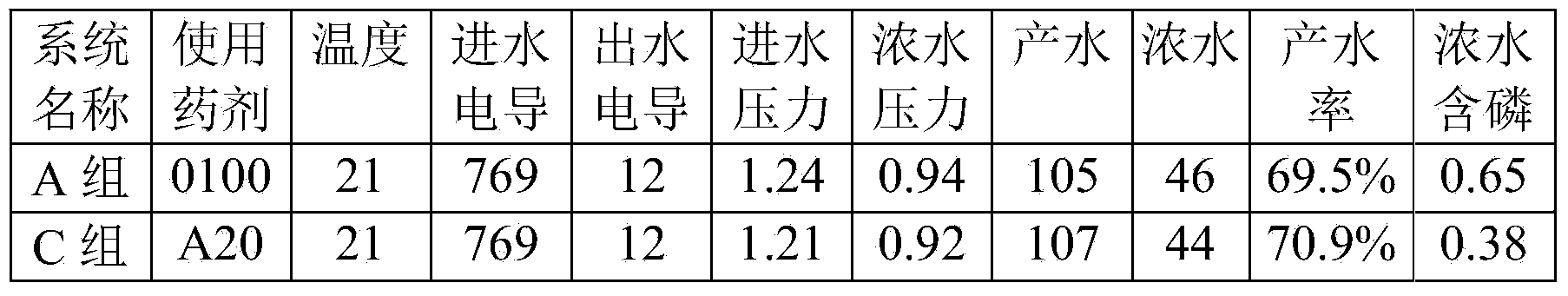

[0016] In order to evaluate the performance of this product, a foreign scale inhibitor PTP-0100 (0100 for short, purchased from Qingli Company of the United States) was selected for comparison with this product.

Embodiment

[0018] Evaluation method: dynamic evaluation method (water supply one-pass method)

[0019] Method introduction: Set the recovery rate of the system operation, and the concentrated water and product water produced by the separation of the feed water through the membrane elements are directly discharged. In the case of constant feed water concentration, judge whether the system is scaled or not by operating parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com