Alternating current servo motor-driven type hydraulic radial forging machine with mechanical travel adjusting function

An AC servo motor and stroke adjustment technology, which is applied to the driving device, mechanical equipment, servo motor, etc. of the forging press, can solve the problems of less energy storage in the system, low strain rate, and inability to adjust the forging curve, etc., so as to increase the bearing capacity of the system , high forging force and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

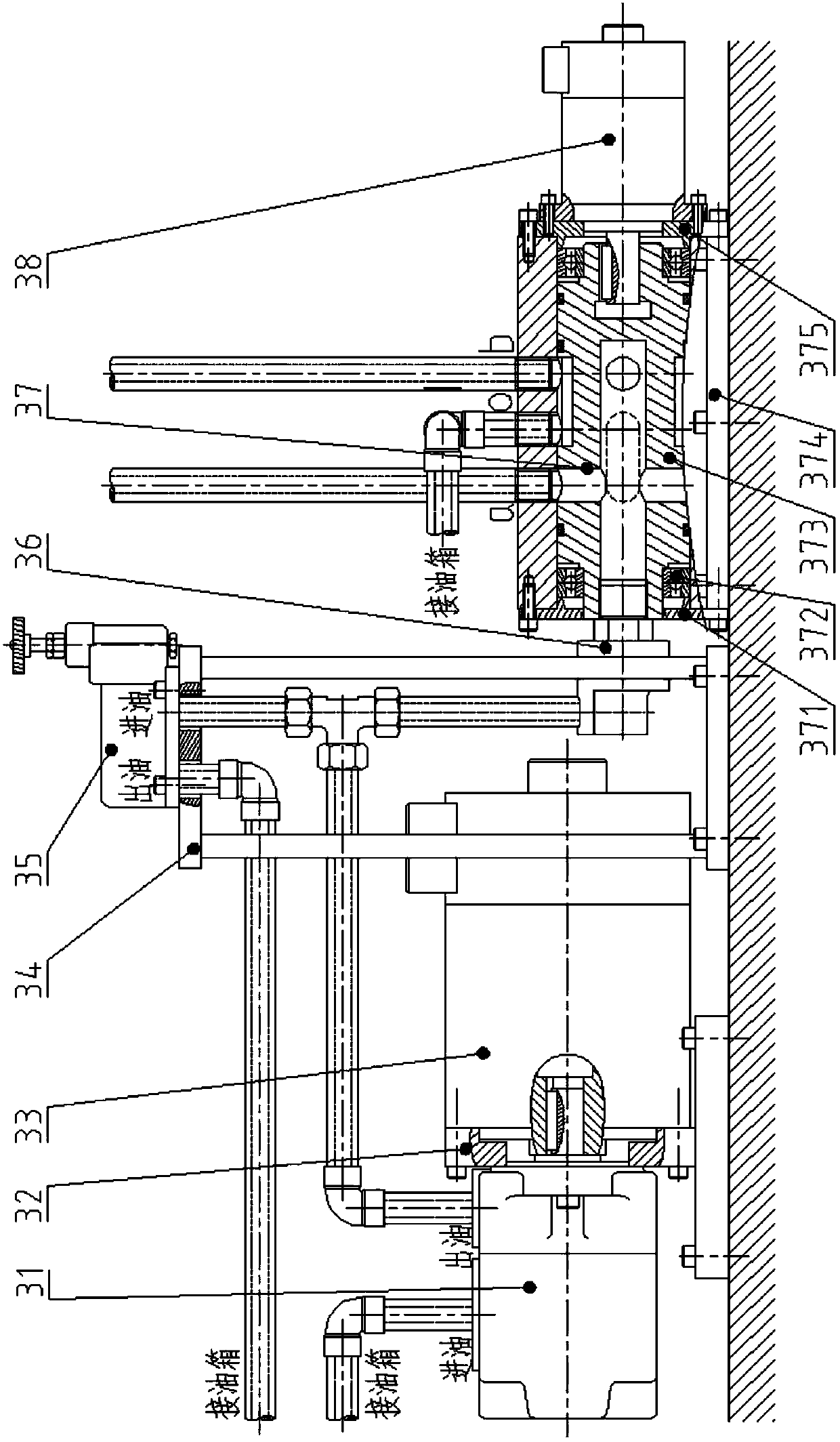

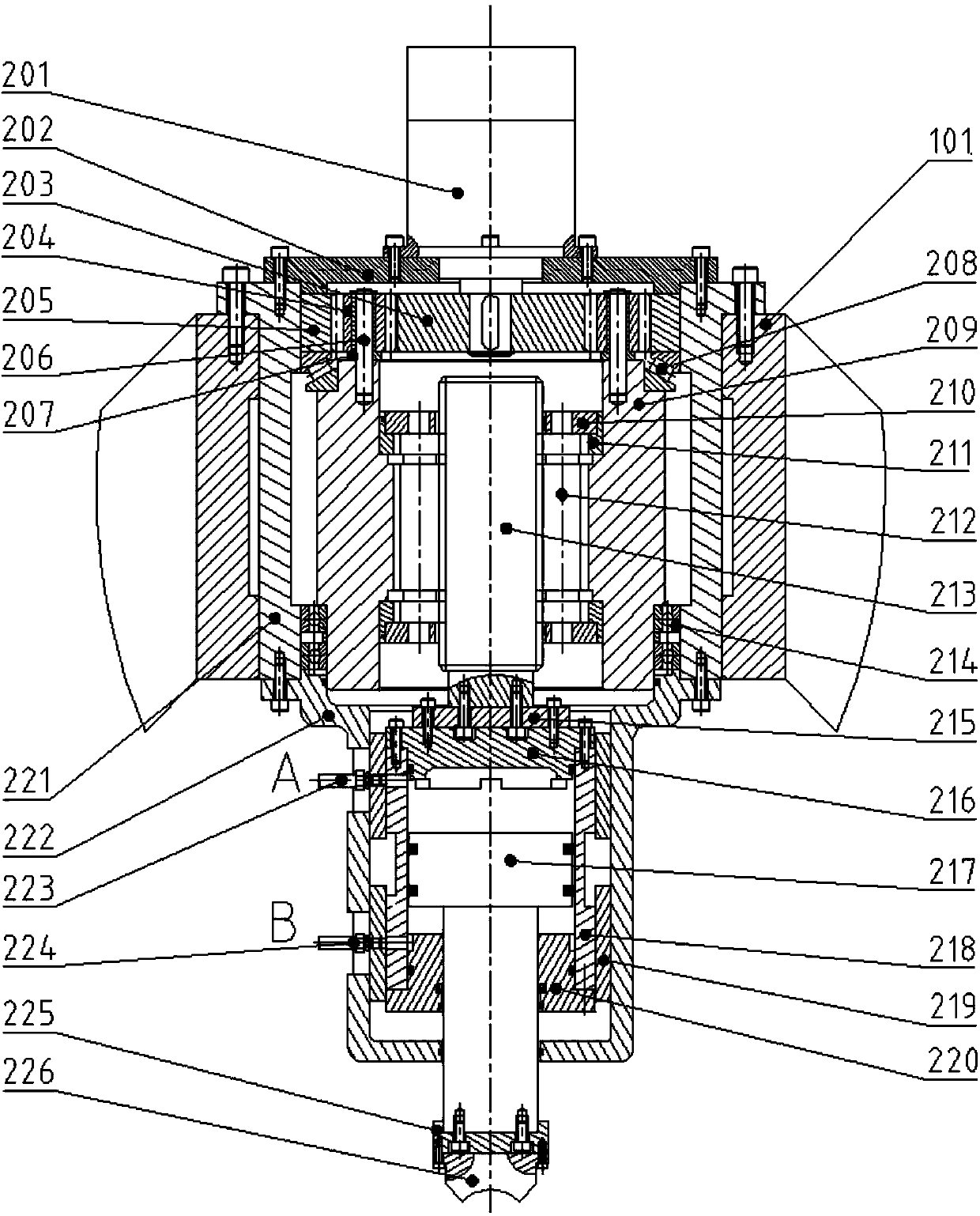

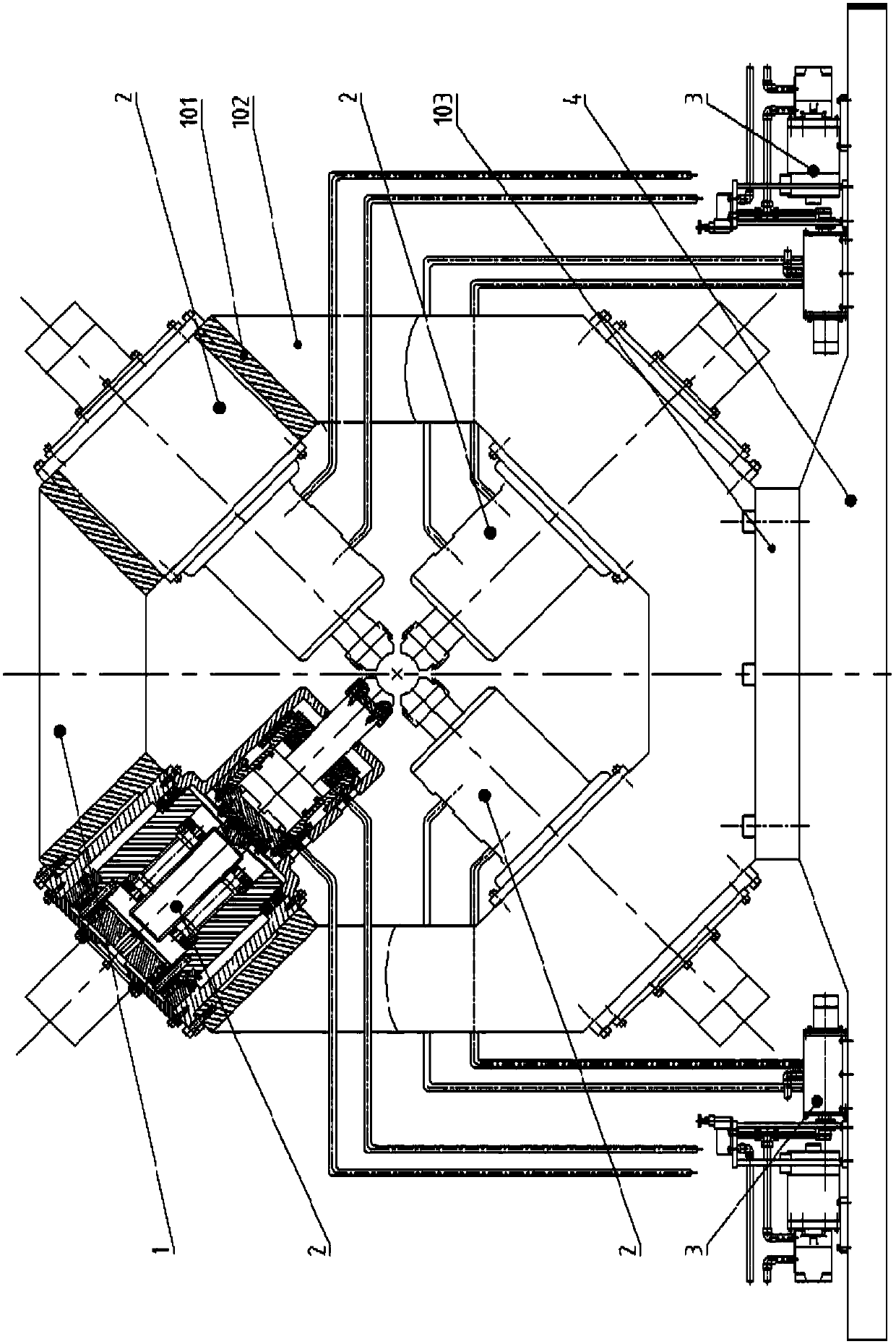

[0019] see figure 1 , a hydraulic radial forging machine driven by an AC servo motor with mechanical stroke adjustment, including a frame 1, on which four installation sleeves 101 are evenly distributed, and four sets of main working mechanisms 2 are installed on the corresponding installation sleeves through bolts 101, so that the system is uniformly arrayed on the circumference, the installation sleeves 101 are connected by welding plates 102, the bottom of the frame 1 is provided with a mounting plate 103 welded thereon, and the frame 1 is installed on the foundation 4 by bolts, each group The main working mechanism 2 uses the main servo motor 201 to drive the planetary screw pair to adjust the position of the hydraulic cylinder after being decelerated by the planetary gear system. The piston rod 217 in the hydraulic cylinder drives the forging die 226 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com