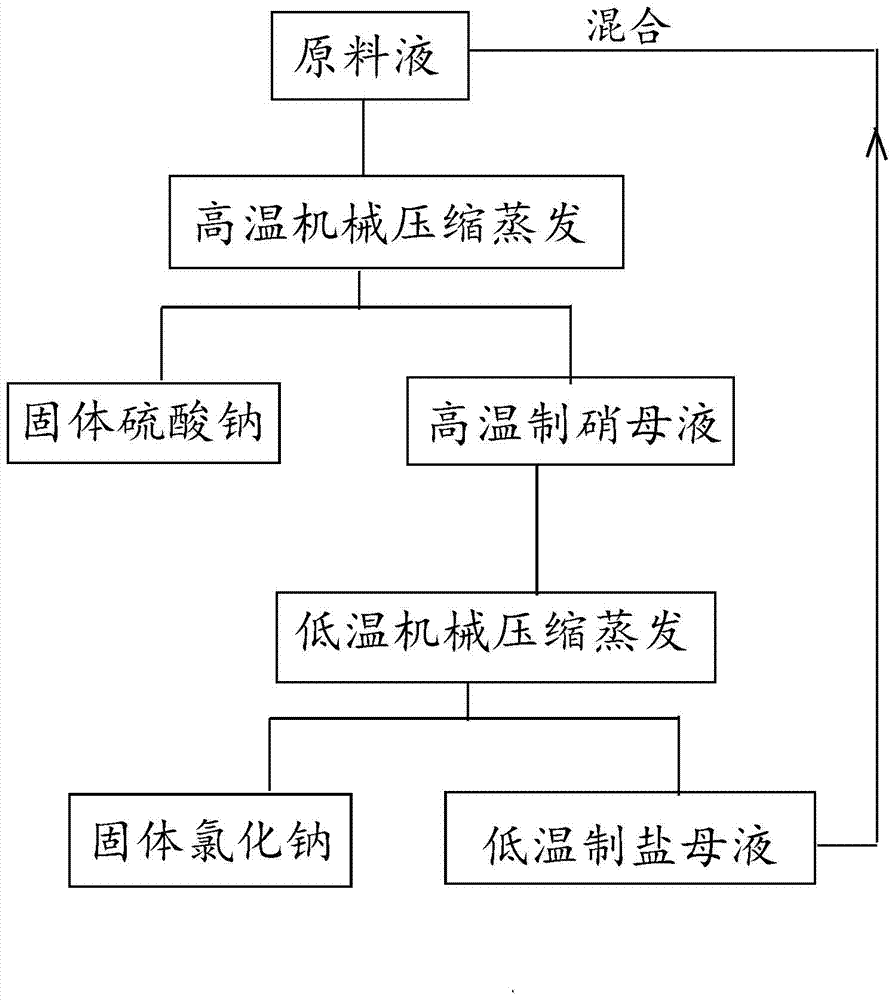

Sodium sulfate and sodium chloride production process

A production process, sodium sulfate technology, applied in the direction of alkali metal chloride, alkali metal sulfite/sulfite, inorganic chemistry, etc., can solve the difficult to adapt to the national policy requirements of energy saving and emission reduction scientific development, shorten the service life of mines , affecting the quality of brine and other issues, to achieve the effect of extending the service life of the mine, strong adaptability of raw materials, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Take 200m 3 Sodium sulfate and sodium chloride solution are raw material liquid (sodium sulfate 310g / l, sodium chloride 50g / l), above-mentioned raw material liquid and low temperature salt making mother liquor 176.17m 3 (sodium chloride 287g / l, sodium sulfate 68g / l) respectively after heat exchange with the condensed water obtained by high-temperature nitrate production and the mother liquor of high-temperature nitrate production, separate and obtain 62 tons of sodium sulfate after high-temperature mechanical compression evaporation at 130 ° C. High temperature nitric acid mother liquor 32.26m 3 (sodium chloride 310g / l, sodium sulfate 60g / l); wherein the raw material solution containing sodium sulfate and sodium chloride solution passes through the condensed water obtained by high-temperature nitrate production and the high-temperature nitrate production mother liquor after heat exchange, and the temperature is raised by 25°C To 130°C, the temperature of the condens...

Embodiment 2

[0023] 1. Take 200m 3 Sodium sulfate and sodium chloride solution are raw material liquid (sodium sulfate 260g / l, sodium chloride 100g / l), above-mentioned raw material liquid and low temperature salt making mother liquor 352.36m 3 (sodium chloride 287g / l, sodium sulfate 68g / l) respectively after heat exchange with the condensed water obtained by high-temperature nitrate production and the mother liquor of high-temperature nitrate production, separate and obtain 52 tons of sodium sulfate after high-temperature mechanical compression evaporation at 130 ° C. High temperature nitric acid mother liquor 64.52m 3 (sodium chloride 310g / l, sodium sulfate 60g / l); wherein the raw material solution containing sodium sulfate and sodium chloride solution passes through the condensed water obtained by high-temperature nitrate production and the high-temperature nitrate production mother liquor after heat exchange, and the temperature is raised by 25°C To 130°C, the temperature of the conden...

Embodiment 3

[0027] 1. Take 200m 3 Sodium sulfate and sodium chloride solution are raw material liquid (sodium sulfate 210g / l, sodium chloride 150g / l), above-mentioned raw material liquid and low temperature salt making mother liquor 528.54m 3 (sodium chloride 287g / l, sodium sulfate 68g / l) respectively after heat exchange with the condensed water obtained by high-temperature nitrate production and the mother liquor of high-temperature nitrate production, separate and obtain 52 tons of sodium sulfate after high-temperature mechanical compression evaporation at 130 ° C. High temperature nitric acid mother liquor 96.77m 3 (sodium chloride 310g / l, sodium sulfate 60g / l); wherein the raw material solution containing sodium sulfate and sodium chloride solution passes through the condensed water obtained by high-temperature nitrate production and the high-temperature nitrate production mother liquor after heat exchange, and the temperature is raised by 25°C To 130°C, the temperature of the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com