Dinonyl naphthalenesulfonic acid and preparation method thereof

A technology of dinonylnaphthalene sulfonic acid and nonylnaphthalene monosulfonic acid, which is applied in the field of dinonylnaphthalene sulfonic acid and its preparation, can solve the problems of increased discharge of industrial three wastes, difficulty in sorting and recycling, and decreased product quality, and achieves The effect of reducing the generation of three wastes, not easy to emulsify, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

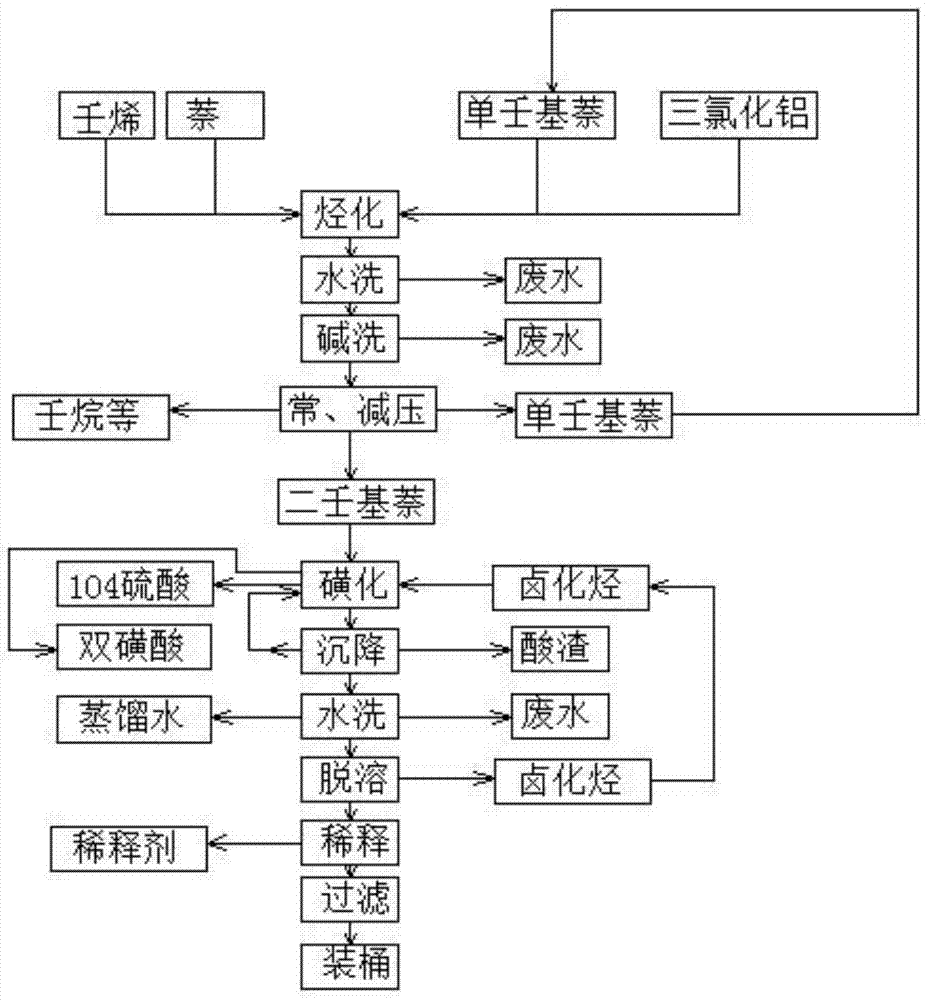

[0027] Such as figure 1 Shown, be the process flow sheet of the present invention, a kind of dinonylnaphthalene sulfonic acid is to be that nonene reacts with naphthalene under the action of aluminum trichloride to generate dinonylnaphthalene, and dinonylnaphthalene reacts with concentrated sulfuric acid again Reaction generates dinonylnaphthalene monosulfonic acid or dinonylnaphthalene disulfonic acid, and the material component and content of dinonylnaphthalene monosulfonic acid and dinonylnaphthalene disulfonic acid are:

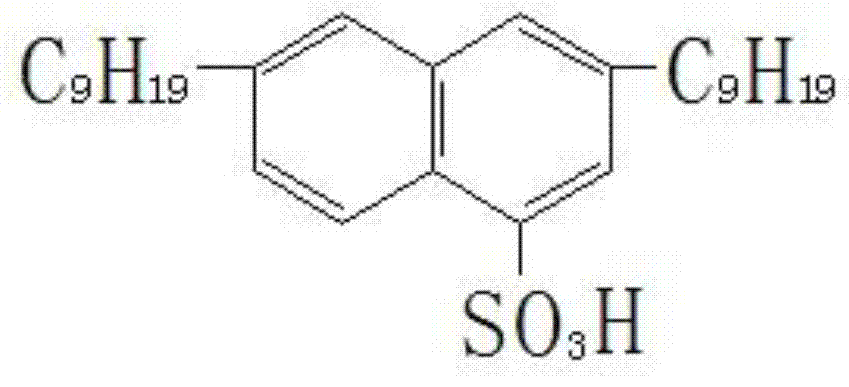

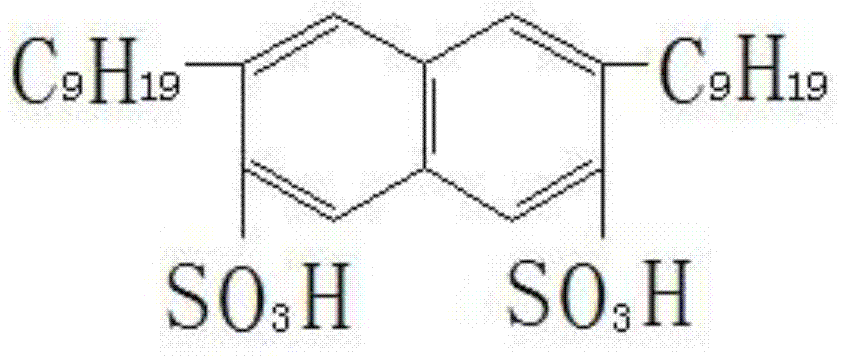

[0028] Nonene 650-750kg, naphthalene 280-350kg, monononylnaphthalene 300-500kg, aluminum trichloride 35-45kg, No. 120 solvent oil 400-500kg, concentrated sulfuric acid 1200-1400kg, liquid caustic soda 120-140kg. The molecular formula of dinonylnaphthalene monosulfonic acid is as follows figure 2 Shown, the molecular formula of dinonyl naphthalene bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com