Method for treating dichlorobenzene rectification residues

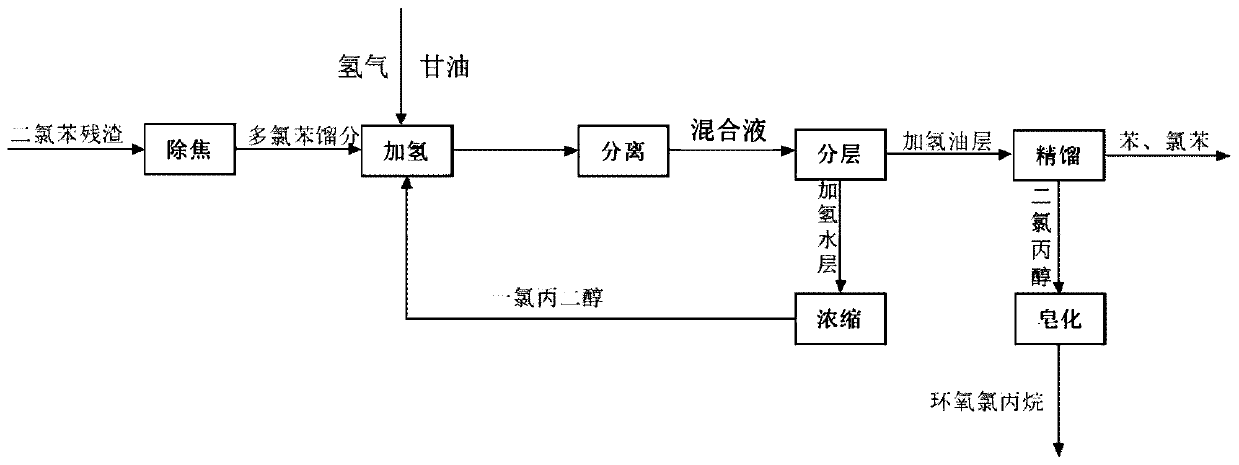

A technology of dichlorobenzene and residues, which is applied in chemical instruments and methods, preparation of dehydrohalogenation, carbon compound catalysts, etc., can solve problems such as ineffective utilization and generation of salty wastewater, achieve good industrial application value, and improve Effect of utilization rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The present embodiment provides a kind of method of processing dichlorobenzene rectification residue, and described method comprises the steps:

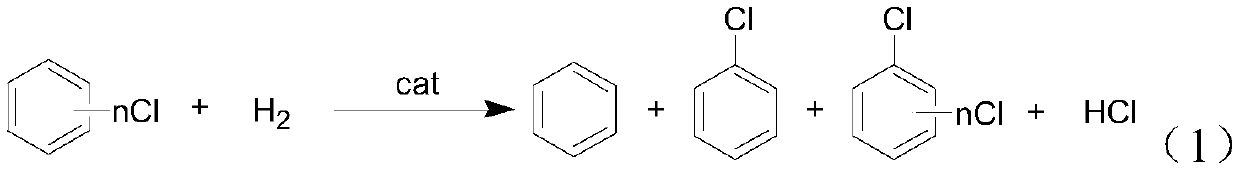

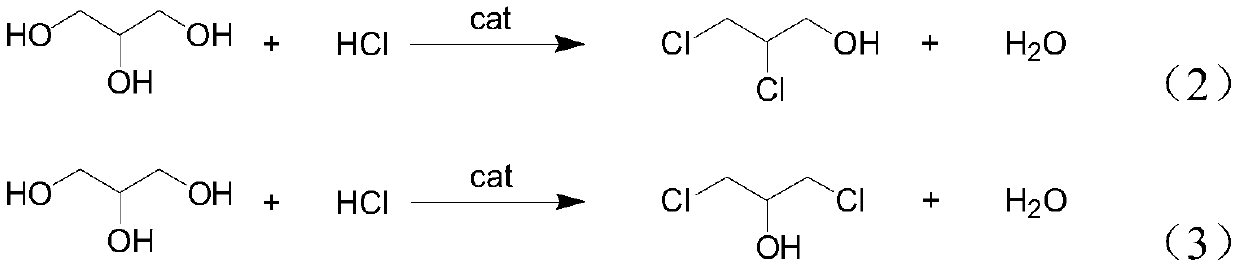

[0084] (1) Under a hydrogen atmosphere, the polychlorobenzene fraction and glycerin collected in vacuum decoking were used as reaction raw materials, and the Rh / Al 2 o 3 Under the effect of supported catalyst and acetic acid, react 1h, make the reaction product that comprises benzene, chlorinated benzene and chloropropanol; Wherein, the mass ratio of described catalyst and reaction raw material is 0.05:1, and the mass ratio of catalyst and acetic acid is 4:1, the molar ratio of glycerol to polychlorobenzene fraction is 0.5:1, the mass ratio of hydrogen to reaction raw materials is 0.009:1, the temperature of the reaction is 110°C, and the pressure is 0.2MPa;

[0085] (2) After the reaction, the temperature is lowered and the pressure is relieved to dismantle the kettle, the reaction product is separated from the catalyst, and...

Embodiment 2

[0088] The present embodiment provides a kind of method of processing dichlorobenzene rectification residue, and described method comprises the steps:

[0089] (1) Under a hydrogen atmosphere, the polychlorobenzene fraction and glycerin collected in vacuum decoking were used as reaction raw materials, and the Rh / SiO 2 Under the action of supported catalyst and n-butyric acid, react 3h, make the reaction product that comprises benzene, chlorinated benzene and chloropropanol; Wherein, the mass ratio of described catalyst and reaction raw material is 0.5:1, the ratio of catalyst and n-butyric acid The mass ratio is 2:1, the molar ratio of glycerol to polychlorobenzene fraction is 1.5:1, the mass ratio of hydrogen to reaction raw materials is 0.019:1, the temperature of the reaction is 130°C, and the pressure is 0.6MPa;

[0090] (2) After the reaction, the temperature is lowered and the pressure is relieved to dismantle the kettle, the reaction product is separated from the cataly...

Embodiment 3

[0093] The present embodiment provides a kind of method of processing dichlorobenzene rectification residue, and described method comprises the steps:

[0094](1) Under a hydrogen atmosphere, the polychlorinated benzene fraction and glycerol collected in vacuum decoking were used as reaction raw materials, and reacted for 3 hours under the action of Rh / C supported catalyst and acetic acid to obtain benzene, chlorinated benzene and chlorine The reaction product of propanol; Wherein, the mass ratio of described catalyzer and reaction raw material is 0.3:1, the mass ratio of catalyzer and acetic acid is 6:1, and the mol ratio of glycerin and polychlorobenzene fraction is 1.1:1, hydrogen and reaction The mass ratio of raw materials is 0.016:1, the temperature of the reaction is 120°C, and the pressure is 0.36MPa;

[0095] (2) After the reaction, the temperature is lowered and the pressure is relieved to dismantle the kettle, the reaction product is separated from the catalyst, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com