Recovery treatment process for waste liquid produced in acetochlor production and treatment device thereof

A technology of recovery and treatment of acetochlor, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of corrosion equipment, difficult filtration, and ineffective recovery of ammonium chloride, etc., to reduce the generation of three wastes , improve the utilization rate of raw materials, and solve the effect of difficult filtration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

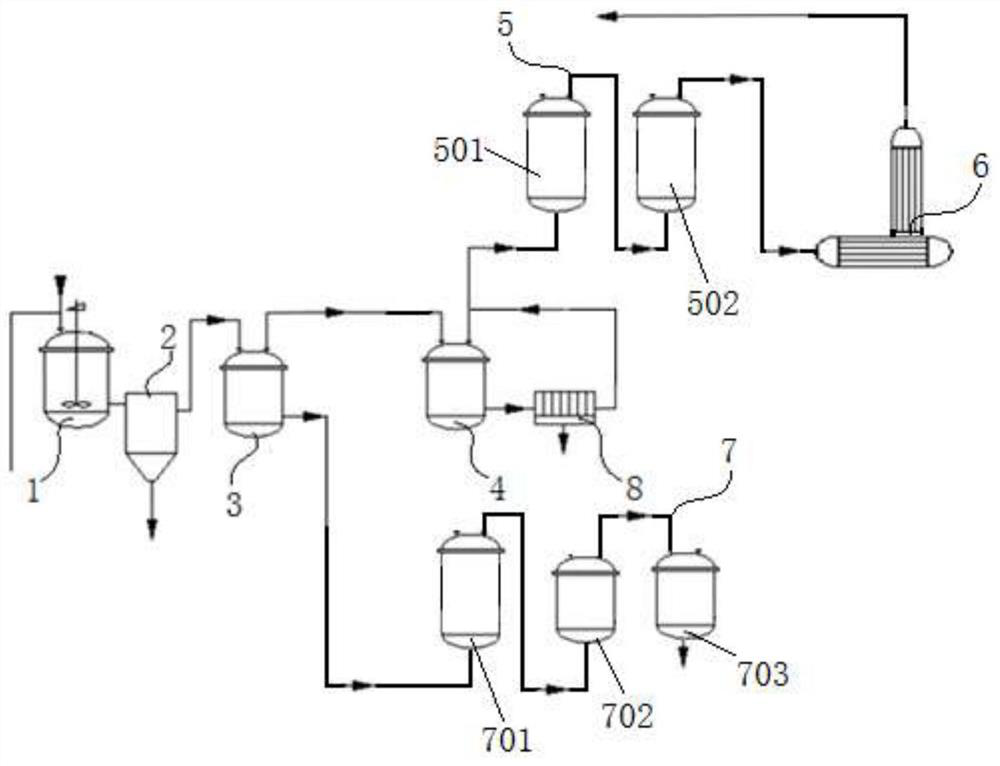

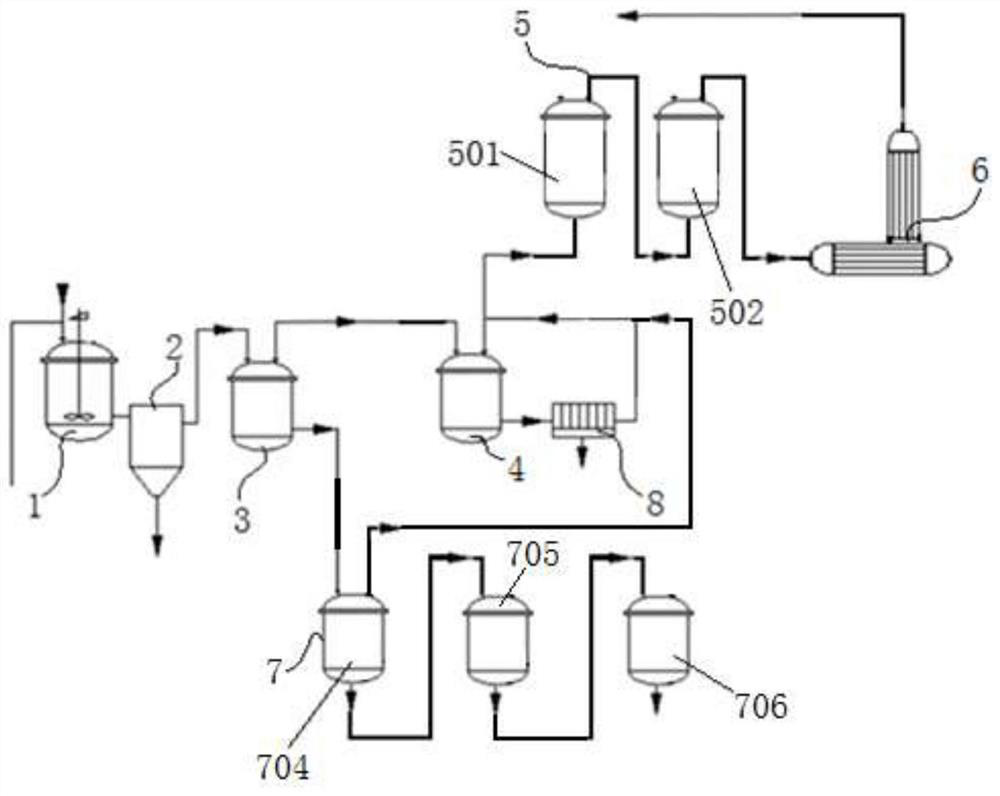

[0071] The recycling process of producing acetochlor output waste liquid comprises the following steps:

[0072] (1) Get 1000mL waste ethanol and carry out secondary distillation, and the cut passes through the impurity removal tower I 501 and the dehydration tower 502 successively, the impurity removal tower I 501 is provided with 18g hydrotalcite, and the dehydration tower 502 is provided with 10g molecular sieves, controlled The temperature inside the impurity removal tower I501 is 65°C, and the steam flow rate of the distillate is 1.3m 3 / h, the fraction passes through the impurity removal tower I 501 and the dehydration tower 502 to obtain crude ethanol.

[0073] (2) The crude ethanol obtained in step (1) is transported to the rectifying tower 6 for rectification to obtain 73.7g of ethanol, the yield of ethanol is 88.1%, its purity is 99.9%, and its moisture content is 260ppm. The ethanol content was analyzed by GC method, and the water content was determined by Karl Fis...

Embodiment 2

[0075] The recovery and treatment process of producing acetochlor output waste liquid is different from Example 1 in that the inorganic dehydrating agent in the dehydration tower 502 of this embodiment is 15g of activated alumina, and the recovery process of this embodiment obtains 71.5g of ethanol , the yield of ethanol was 85.4%, its purity was 99.9%, and the moisture content was 250ppm.

Embodiment 3

[0077] The recovery and treatment process of producing acetochlor output waste liquid is different from Example 1 in that the present embodiment controls the temperature of the deacidification tower 5 to be 60 ° C, and the purity of the ethanol obtained by the recovery process of the present embodiment is 99.91%. The moisture content was 200 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com