A flame retardant phenolic foam board

A phenolic foam board, flame retardant technology, applied in the field of mixed foaming of phenolic resin and flame retardant, can solve the problems of small application fields, harmful to the environment and human body, high energy consumption, etc., to improve flame retardant performance and reduce density , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

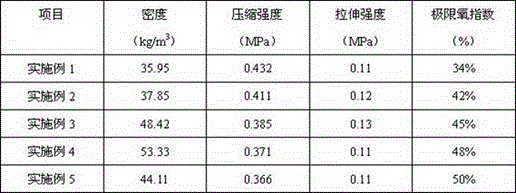

Examples

preparation example Construction

[0015] A preparation method of flame-retardant phenolic foam board, comprising the following steps:

[0016] Mix 50-70 parts by weight of basic phenolic resin, 7-30 parts by weight of flame retardant, 5-15 parts by weight of foaming agent, 15-30 parts by weight of water and 10-30 parts by weight of curing agent, Heating and foaming in an environment with a temperature of 50°C~90°C and a humidity of 40%~90%, curing and molding to obtain a phenolic foam board.

[0017] As a preferred solution, the present invention first mixes flame retardant, phenolic resin, and stabilizer, then stirs at high speed evenly, then adds foaming agent and mixes evenly, then adds water and curing agent, mixes evenly, pours it into the mold, and foams Foam curing molding, the reaction temperature is preferably 40°C~80°C, more preferably 50°C~70°C, most preferably 60°C~70°C.

[0018] The phenolic resin used in the present invention is preferably a basic phenolic resin, and the basic phenolic resin is ...

Embodiment 1

[0027] Calculated in parts by weight, each gram is one part, and each component raw material is weighed:

[0028] 70 parts of foamable basic phenolic resin, no flame retardant added, 12 parts of n-pentane, 20 parts of water, 20 parts of sulfuric acid with pH=2, 3 parts of polyethylene glycol, and 5 parts of polyurethane prepolymer.

[0029] The raw material mixture obtained by stirring is poured into a mold, and foaming and curing are carried out in a constant temperature box with a temperature of 70° C. and a humidity of 50% for 2 hours. After obtaining the phenolic foam board, dry it at room temperature to obtain the required pure phenolic foam board.

Embodiment 2

[0031] Calculated in parts by weight, each gram is one part, and each component raw material is weighed:

[0032] 63 parts of foamable alkaline phenolic resin, 7 parts of tetrabromobisphenol A, 12 parts of n-pentane, 20 parts of water, 20 parts of sulfuric acid with pH=2, 3 parts of polyethylene glycol, and 5 parts of polyurethane prepolymer.

[0033] The raw material mixture obtained by stirring is poured into a mold, and foaming and curing are carried out in a constant temperature box with a temperature of 70° C. and a humidity of 50% for 2 hours. After obtaining the phenolic foam board, it is then dried at room temperature to obtain the desired phenolic foam board modified with a flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com