A kind of preparation method of vanadium-titanium tailings ceramic heat collecting plate

A technology of ceramic heat collection and tailings, which is applied in the direction of heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problems of low efficiency and achieve the effect of reducing production costs and strengthening decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Preparation of the heat-collecting layer (1): Mix the Yellow River silt, vanadium-titanium tailings with a weight ratio of 50:50 plus ceramic pigments with a weight percentage of 5%, and melt them in a frit furnace at a temperature of 1350°C Process to make heat-collecting layer frit particles with a particle size of 0.1mm;

[0019] b. Preparation of the transition layer (2): uniformly mix and grind the heat-collecting layer frit particles prepared in step a with 5% by weight of mullite until the particle size is 10 μm to make the transition layer raw material;

[0020] c. Preparation of the heat-insulating layer (3): uniformly mix the frit particles of the heat-collecting layer prepared in step a plus 5% coal gangue by weight, and spray granulate to make the raw material of the heat-insulating layer with a particle size of 0.1 mm;

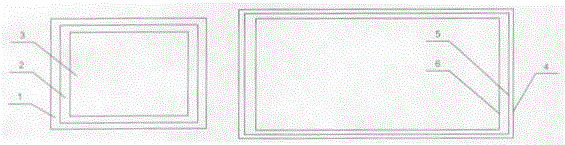

[0021] d. Preparation of vanadium-titanium tailings ceramic heat collector plate: first adopt the setter plate (4) left, right, front, ...

Embodiment 2

[0023] a. Preparation of the heat-collecting layer (1): Mix the Yellow River silt, vanadium-titanium tailings with a weight ratio of 70:30 plus ceramic pigments with a weight percentage of 18%, and melt them in a frit furnace at a temperature of 1400°C Process to make heat-collecting layer frit particles with a particle size of 1mm;

[0024] b. Preparation of the transition layer (2): uniformly mix and grind the heat-collecting layer frit particles prepared in step a with 13% by weight of mullite until the particle size is 30 μm to make the transition layer raw material;

[0025] c. Preparation of the heat-insulating layer (3): uniformly mix the frit particles of the heat-collecting layer prepared in step a with 12% by weight of coal gangue, and spray granulate to make a raw material for the heat-insulating layer with a particle size of 0.5 mm;

[0026] d. Preparation of vanadium-titanium tailings ceramic heat collector plate: first adopt the setter plate (4) left, right, fron...

Embodiment 3

[0028] a. Preparation of the heat-collecting layer (1): Mix the Yellow River silt, vanadium-titanium tailings with a weight ratio of 90:10 plus ceramic pigments with a weight percentage of 30%, and melt them in a frit furnace at a temperature of 1450°C Process to make heat-collecting layer frit particles with a particle size of 2mm;

[0029] b. Preparation of the transition layer (2): uniformly mix and grind the heat-collecting layer frit particles prepared in step a with 20% by weight of mullite until the particle size is 50 μm to make the transition layer raw material;

[0030] c. Preparation of the insulation layer (3): uniformly mix the heat-collecting layer frit particles prepared in step a plus 30% by weight of coal gangue, and spray granulate to make the insulation layer raw material with a particle size of 1 mm;

[0031] d. Preparation of vanadium-titanium tailings ceramic heat collector plate: first adopt the setter plate (4) left, right, front, back and bottom surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com