Large-cavity length micro-electro-mechanical tunable fabry-perot filter

A Perot filter, micro-electromechanical technology, applied in instruments, optical components, optics, etc., can solve the problems that it is difficult to realize narrow full width at half maximum and wide free spectral range at the same time, and the length of the Bury-Perot filter cavity. , to achieve the effect of simple structure, guaranteed parallelism, and low-voltage drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

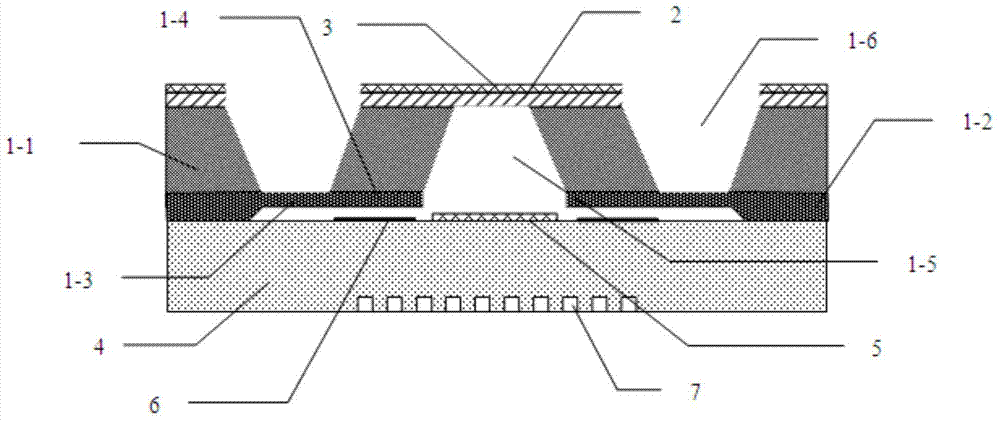

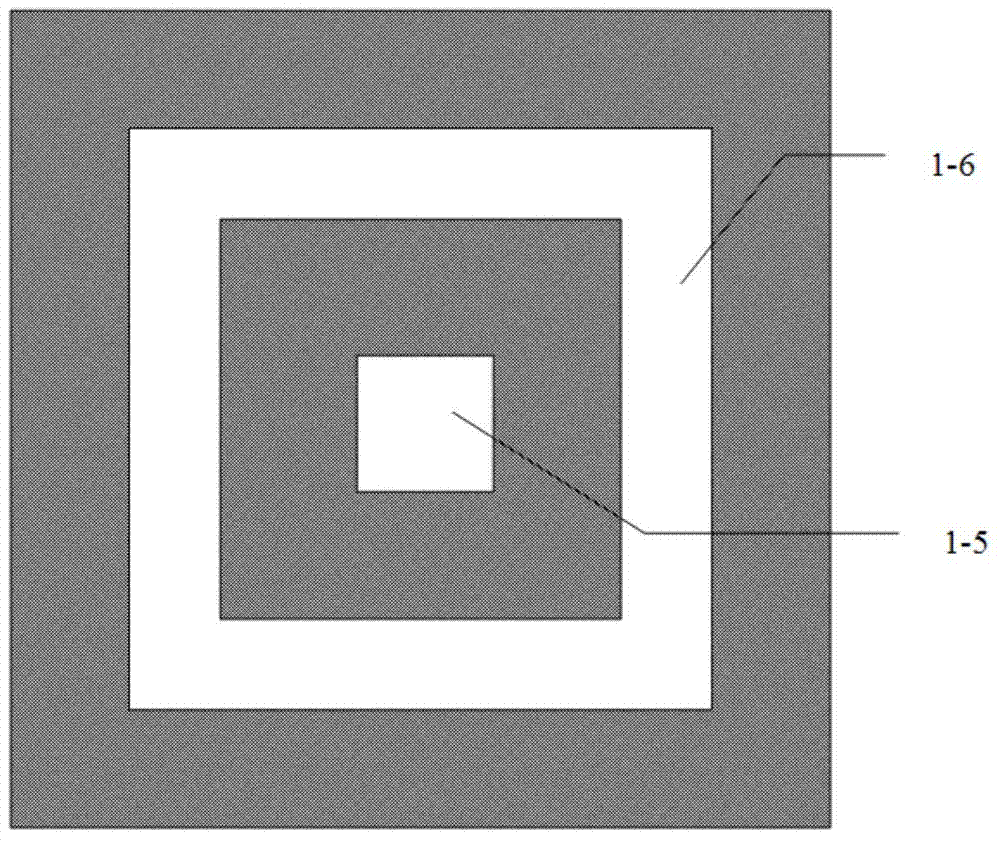

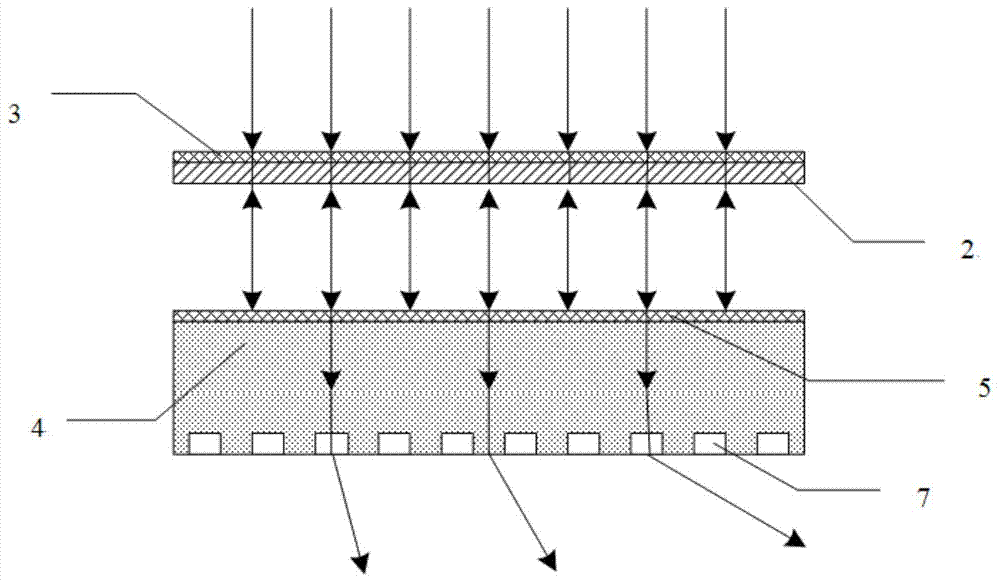

[0034] Embodiment 1 of the present invention is a MEMS tunable Fabry-Perot filter with a cavity length of 200 μm, its spectral range is 400nm-800nm, and the full width at half maximum is less than 0.05nm. The cross-sectional diagram of the filter is shown in figure 1 As shown, the upper substrate includes: a "W"-shaped bulk silicon 1-1 after double-sided etching, a dense boron-doped layer 1-2 on the lower surface of the "W"-shaped bulk silicon, a cantilever beam 1-3, and an upper electrode 1- 4. The central hollow area 1-5 of "W" shape silicon, the surrounding hollow area 1-6 of "W" shape silicon, the supporting film of front cavity mirror 2, and the front cavity mirror 3; the lower substrate includes: quartz substrate 4, rear cavity Mirror 5, lower electrode 6 and diffraction grating 7.

[0035]The "W" shape silicon 1-1 and its lower surface concentrated boron-doped layer 1-2 are used as the upper substrate of the MEMS tunable Fabry-Perot filter, with a total thickness of 20...

Embodiment 2

[0039] Embodiment 2 of the present invention is a MEMS tunable Fabry-Perot filter with a cavity length of 500 μm, its spectral range is 1.3 μm-1.7 μm, and the full width at half maximum is less than 0.1 nm. The structure of this filter is similar to Embodiment 1, only the size is different.

[0040] The "W" shape silicon 1-1 and its lower surface densely boron-doped layer 1-2 are used as the upper substrate of the MEMS tunable Fabry-Perot filter. The total thickness is 500 μm, which determines the MEMS tunable method. The initial cavity length of the Bry-Perot filter. Among them, the thickness of the boron-doped layer 1-2 on the lower surface is 15 μm, and its processed area is thinned by 4 μm. The purpose of thinning is to determine the thickness of the cantilever beam 1-3 and the thickness of the upper and lower electrodes (1-4 and 6). spacing. The dimensions of the central hollow area 1-5 of the "W" shape silicon 1-1 are 2 mm x 2 mm in length x width on its upper surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com