Multi-chip type high-voltage driving circuit

A high-voltage drive circuit, multi-chip technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems affecting the normal operation of devices and high operating voltage of devices, so as to save manufacturing costs, reduce adverse effects, and reduce process complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

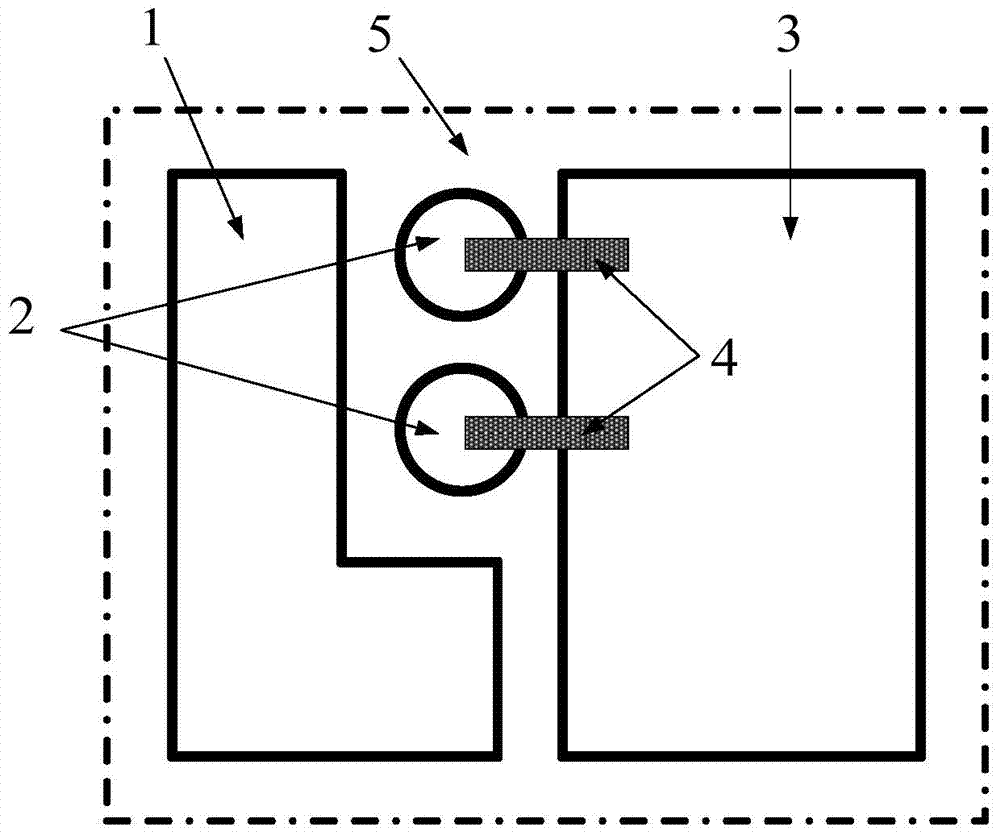

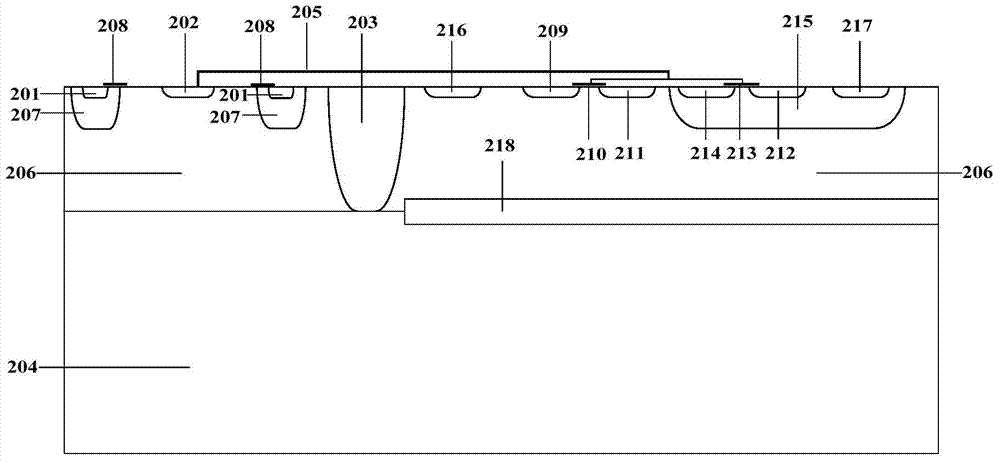

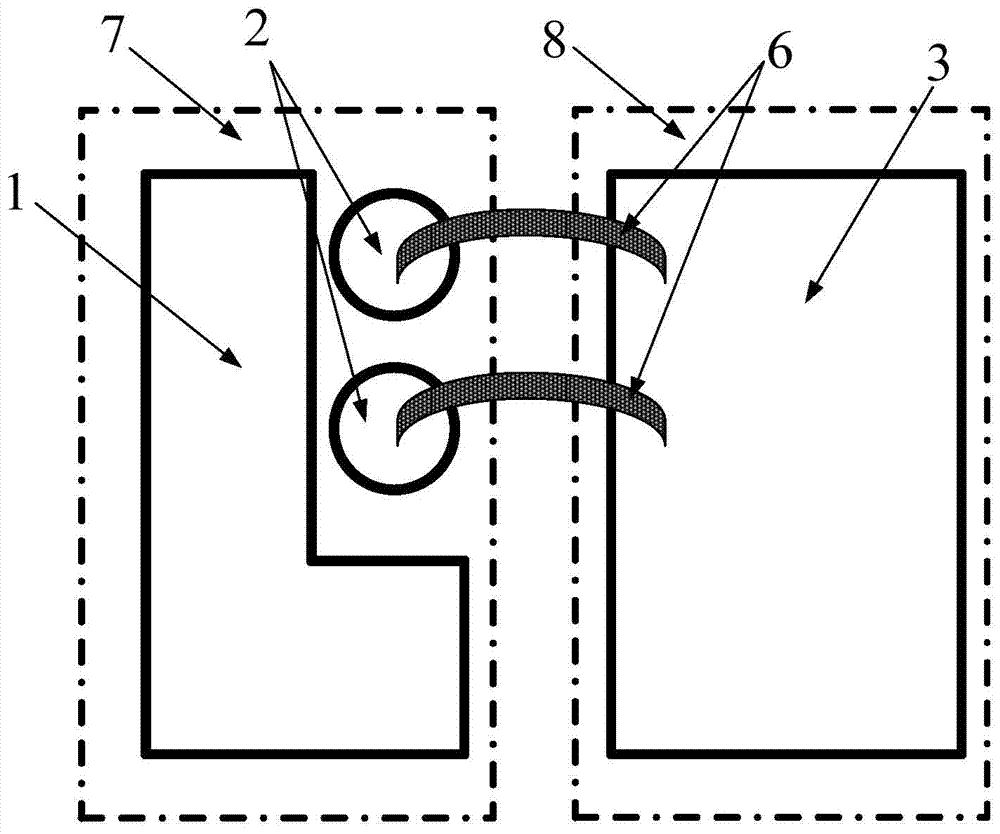

[0023] The invention provides a multi-chip high-voltage drive circuit, which can significantly enhance the withstand voltage of the device when there are high-voltage interconnection lines; at the same time, the multi-chip circuit structure avoids the high-end circuit area and the lateral direction for level shifting. Leakage between power devices, and make the substrate potential in the high-end circuit area a floating ground potential, avoiding the punch-through between the substrate and the surface device; the high-end circuit can be realized using a standard CMO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com