Rotor iron core convenient to produce

A rotor core and iron core technology, applied in the field of machinery, can solve problems such as lack of market competitiveness and low production efficiency, and achieve the effects of reducing manufacturing costs, simplifying workload, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

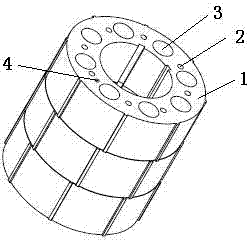

[0014] Such as figure 1 As shown, a rotor core that is easy to manufacture includes several iron sheets 1 stacked together. The iron sheets 1 are provided with several rivet holes 2 and cooling holes 3 that are easy to pass through. The iron sheets 1 Evenly distributed and stacked into three iron core groups connected together, which are the first iron core group, the second iron core group and the third iron core group; the rotor structure composed of three iron core groups can make the motor run more smoothly , the torque ripple is smaller. Each iron core group is composed of several iron chips 1, and each iron chip 1 is provided with two groups of evenly distributed rivet holes 2, each group of rivet holes is four, and each iron chip 1 has There are two keyways, and the two keyways are distributed at 45° in the circumferential direction. One rivet hole 2 in one set of rivet holes is on the same radius line as one of the keyways, and one rivet hole 2 in the other set of riv...

Embodiment 2

[0016] Such as figure 1 As shown, a rotor core that is easy to manufacture includes several iron sheets 1 stacked together. The iron sheets 1 are provided with several rivet holes 2 and cooling holes 3 that are easy to pass through. The iron sheets 1 Evenly distributed and laminated into three iron core groups connected together, which are the first iron core group, the second iron core group and the third iron core group; each iron core group is composed of several iron chips 1, so Each iron chip 1 described above is provided with two groups of evenly distributed rivet holes 2, and each group of rivet holes 2 is 4. At the same time, each iron chip 1 is provided with two key grooves, and the two key grooves are arranged in the circumferential direction. 55°distribution, one rivet hole 2 in one group of rivet holes is on the same radius line as one of the keyways, and one rivet hole 2 in the other group of rivet holes is on the same radius line as the other keyway. 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com