A kind of copper zirconium catalyst, preparation method and application

A copper-zirconium catalyst and copper-zirconium technology, which are applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of improper control of catalyst active precursors, difficulty in washing and filtering catalyst precursors, etc. Solve the difficulty of washing and filtration, good industrial value, and improve the effect of reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

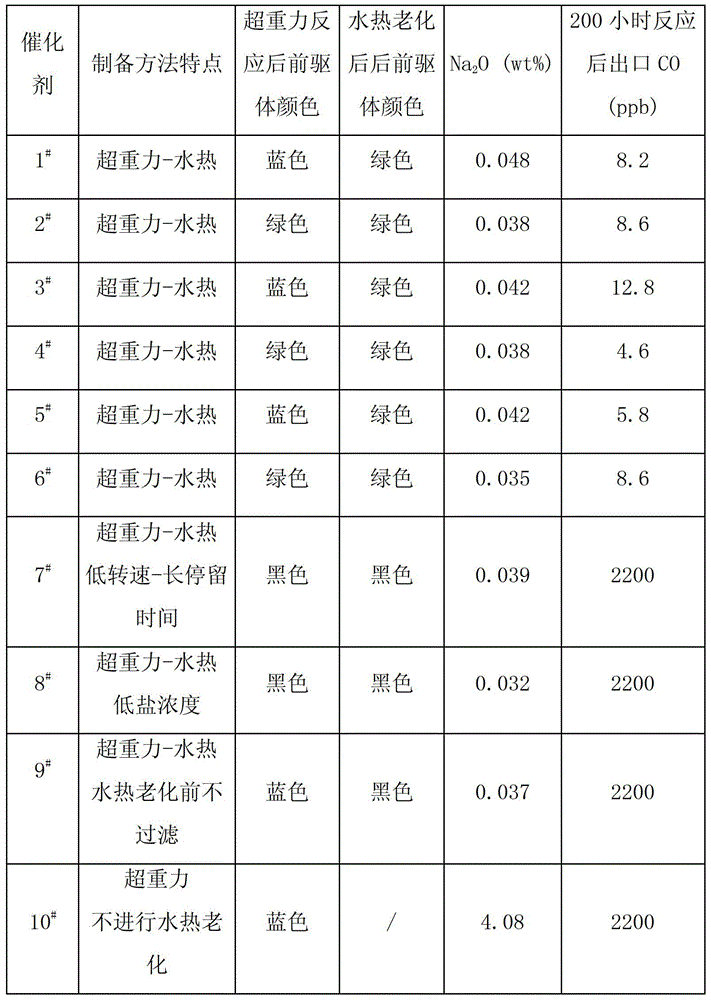

Embodiment 1

[0054] Configure 5 cubic meters of total salt molar concentration as a mixed solution of nitric acid and zirconium oxychloride (according to CuO / ZrO in the catalyst) 2 The weight ratio is 30 / 70) and 5 cubic meters of 2.0mol / L sodium carbonate solution are added to the high-gravity reactor in parallel flow for neutralization. The neutralization reaction temperature is 80°C, and the rotor speed of the high-gravity reactor is 2000rpm , The residence time of the material in the reactor is 2 minutes, and the pH value of the blue slurry coming out of the supergravity reactor is 8.5. The feed liquid from the high-gravity rotary reactor is aged at 80°C in the aging tank, and the aging is stopped after the feed liquid turns green. The mother liquor was removed by pressure filtration.

[0055] The precursor obtained in the above process was filtered and re-dispersed in water. After the above materials were diluted with deionized water, they were introduced into a hydrothermal stirring ...

Embodiment 2

[0057] Other conditions are with embodiment 1. The rotor speed of the supergravity reactor is 2000rpm, the residence time of the material in the reactor is 0.5 minutes, and the pH value of the slurry coming out of the supergravity reactor is 7.5. The slurry that came out at this time had turned into a green slurry. Na after washing 2 The O content (calculated on a dry base copper-zirconium composite oxide) is 0.048wt%. The prepared catalyst is 2 # . Component content is 30wt%CuO / 70wt%ZrO 2 .

Embodiment 3

[0059] Other conditions are with embodiment 1. The concentration of the composite copper-zirconium mixed salt solution is 5M, the concentration of the sodium carbonate solution is 0.5M, the rotor speed of the supergravity reactor is 100rpm, the residence time of the material in the reactor is 5 minutes, and the pH value of the slurry coming out of the supergravity reactor is 6.5 . The slurry that came out at this time had turned into a green slurry. Na after washing 2 The O content (calculated on a dry base copper-zirconium composite oxide) is 0.042wt%. The prepared catalyst is 3 # . Component content is 15wt%CuO / 85wt%ZrO 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com