Method for preparing ZSM-5 zeolite molecular sieve, product and purpose thereof

A technology of ZSM-5 and zeolite molecular sieve, which is applied in the field of molecular sieve to achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

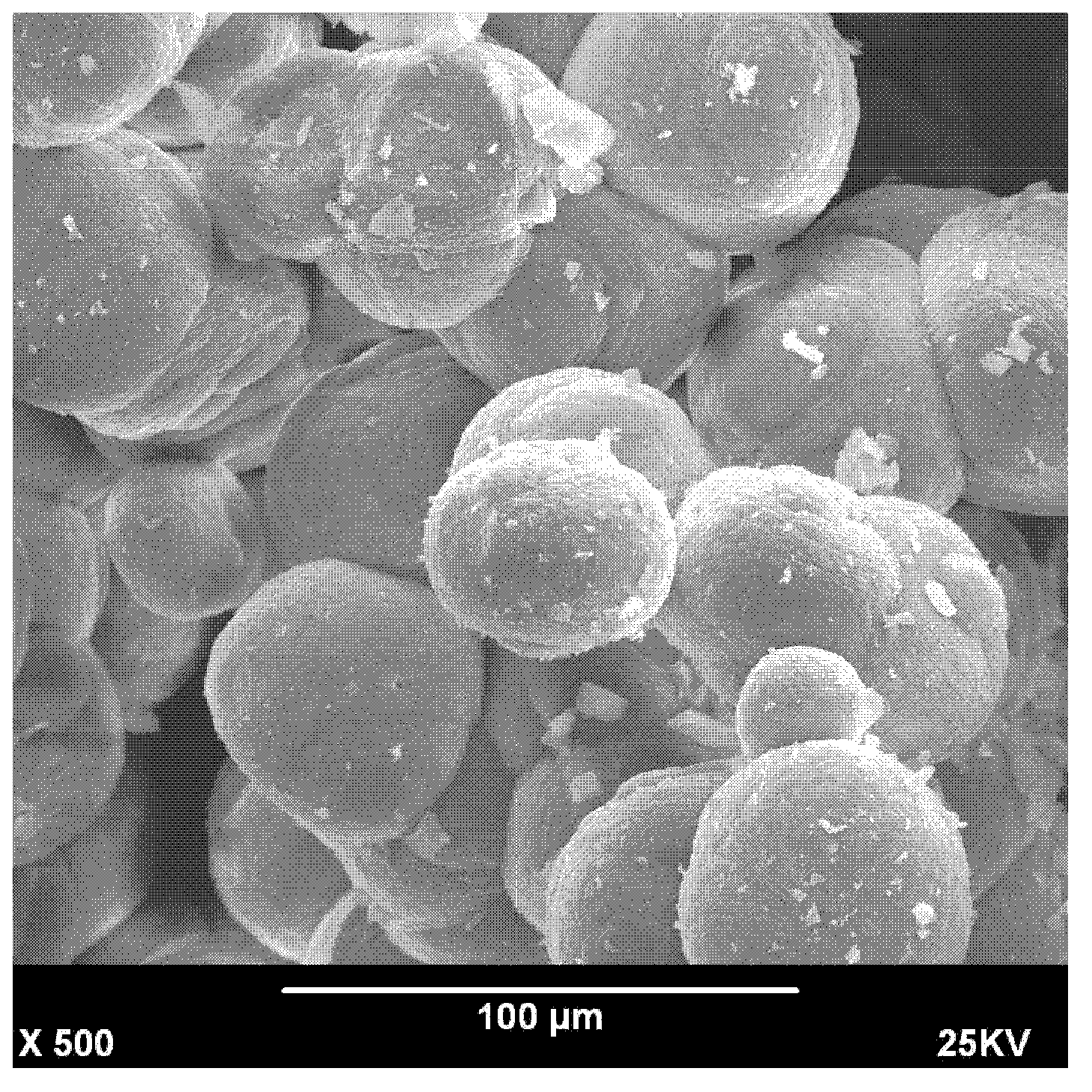

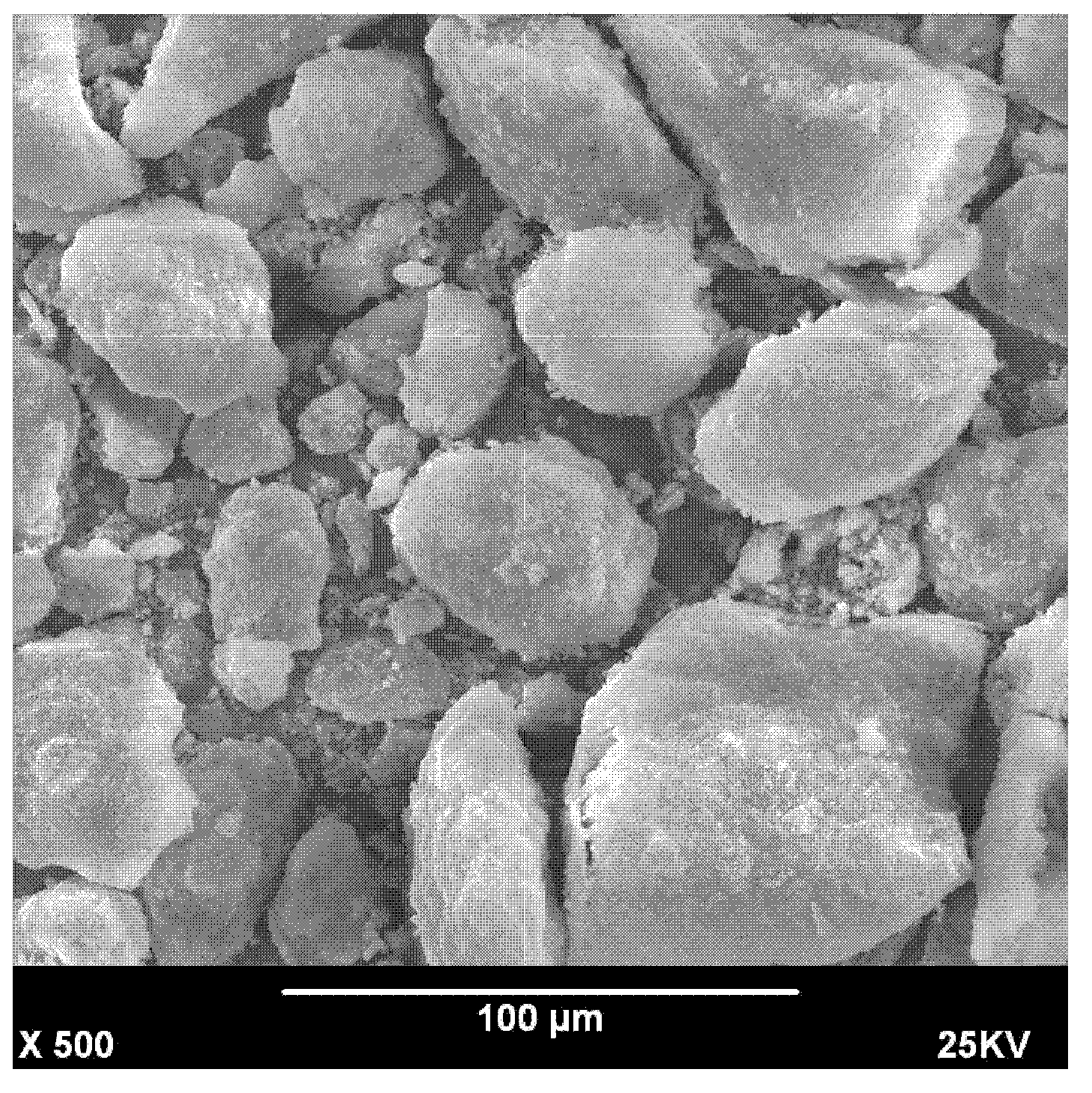

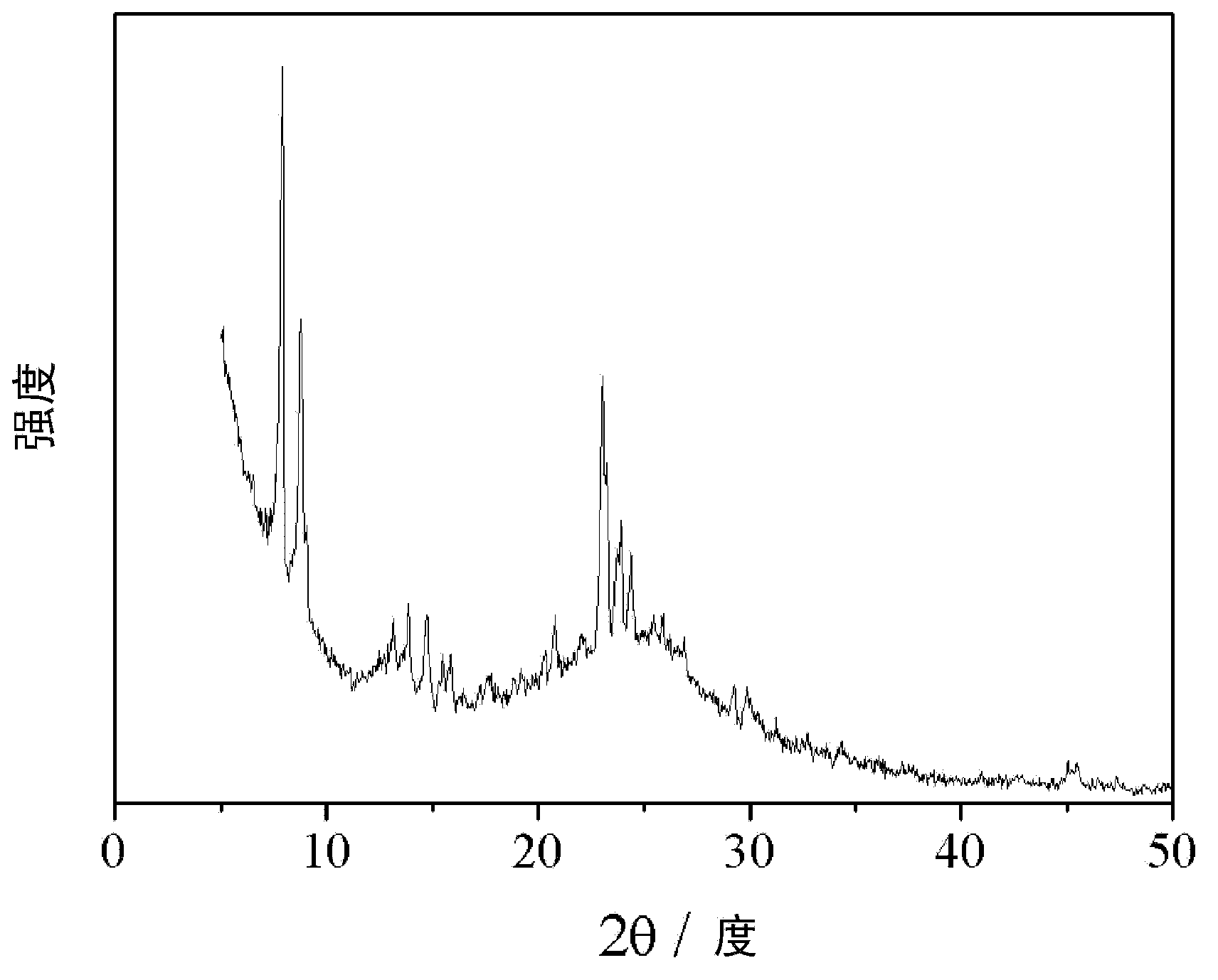

[0025] The invention provides a method for synthesizing a ZSM-5 zeolite molecular sieve with a hierarchical pore structure, the hierarchical pore structure includes micropores and mesopores, and may also contain macropores; wherein the diameter of the micropores is 0.51-0.58nm , the mesopore diameter is 2~50nm, and the macropore diameter is 50~200nm; The method comprises the following steps:

[0026] (1) Preparation of initial gel: Add silicon source and aluminum source to a certain amount of water according to a certain ratio, after stirring evenly, add alkali to adjust the pH value of the system to alkaline (preferably range 8 to 13), then add ZSM-5 zeolite molecular sieve template and gemini-type cationic mesoporous directing agent, and continue stirring for 1 to 8 hours to obtain an initial gel;

[0027] (2) Hydrothermal crystallization: transfer the initial gel prepared in step (1) to a high-pressure synthesis kettle, and conduct hydrothermal crystallization under autogen...

Embodiment 1

[0046] Example 1: Preparation of ZSM-5 zeolite molecular sieve samples 1-12

[0047] Add silicon source and aluminum source to a certain amount of water according to a certain ratio, and after stirring evenly, add alkali under continuous stirring at 30°C to adjust the pH value of the reaction system to pH=8-13 (the specific values are listed in Table 1 middle), then add ZSM-5 zeolite molecular sieve template agent and gemini-type cation mesoporous directing agent, and continue to stir for 5 hours to obtain the initial gel; move the prepared reaction sol into a stainless steel high-pressure synthesis kettle and seal it in 100~180℃, hydrothermal crystallization under autogenous pressure for 1~5 days. The hydrothermal crystallized solid product was centrifuged, washed with deionized water until neutral, dried in air at 110°C for 36h, and finally calcined in a muffle furnace at 550°C for 8h to remove ZSM-5 zeolite A molecular sieve template and a gemini-type cation mesoporous d...

Embodiment 2

[0050] Example 2: Chemical composition of samples 1-12 prepared in Example 1

[0051] Samples 1-12 prepared in Example 1 are carried out chemical composition measurement by an elemental analyzer, and the adopted instrument is a Magix (PHILIPS) type X-ray fluorescence analyzer. + The standard-free quantitative analysis program corresponds the fluorescence intensity of the standard sample to its standard composition, and deducts the influence of interference spectral lines.

[0052] The result measured by the elemental analyzer is the percentage content of oxides of each element. The chemical composition of the sample can be obtained by inverting the percentage content of the oxide of the element. The chemical composition conforms to the general formula Na X Si Y Al Z o T or K X Si Y Al Z o T , wherein, Y≥10; T=1 / 2·X+2Y+3 / 2·Z.

[0053] Take samples 9 and 12 as examples. In sample 9, the weight percentage of each element is Na 2 O%=0.12%, SiO 2 %=98.16%, Al 2 o 3 %...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com