Polycarbonate diol, thermoplastic polyurethane, coating composition and coating film

A technology of polycarbonate diol and composition, applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problem of requiring a large amount of solvent, and achieve the effect of excellent wear resistance and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

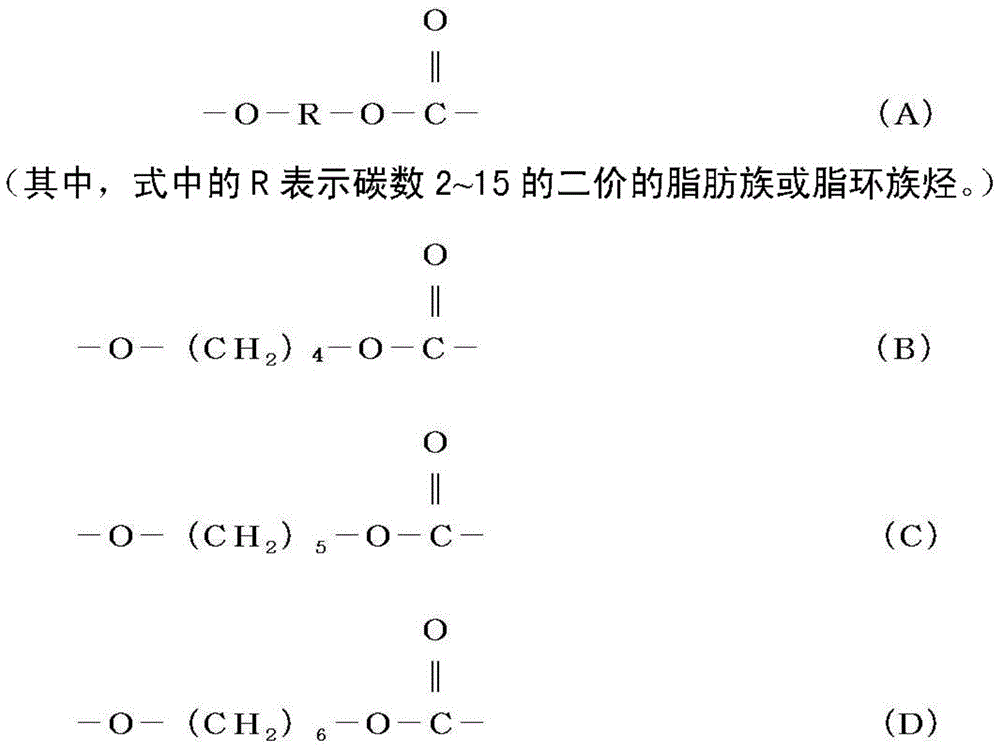

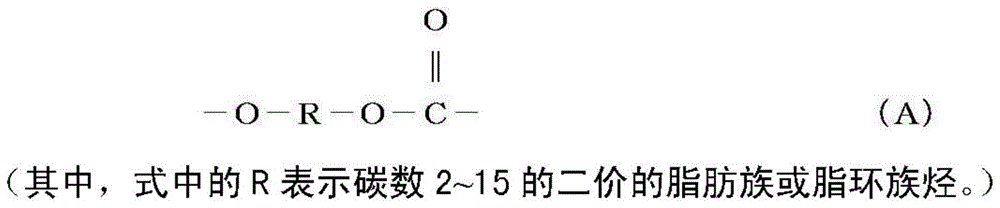

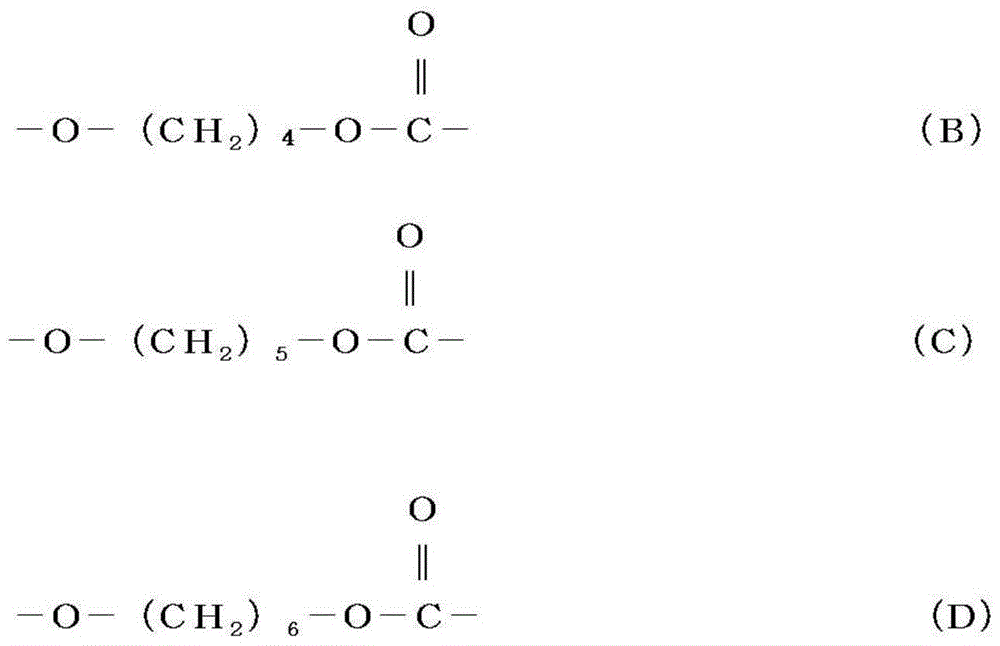

Method used

Image

Examples

Embodiment 1

[0099] 840 g (7.1 mol) of diethyl carbonate, 240 g (2.7 mol) of 1,4-butanediol, 1,5-pentanediol, and 360 g (3.5 mol) of alcohol and 175 g (1.5 mol) of 1,6-hexanediol. Furthermore, 0.5 g of titanium tetrabutoxide was added as a catalyst, and it stirred and heated under normal pressure. Next, the reaction temperature was gradually raised from 150° C. to 190° C., and the reaction was carried out for 15 hours while distilling off a mixture of ethanol and diethyl carbonate produced. Thereafter, the reaction was further performed at 190° C. for 8 hours while reducing the pressure to 15 kPa and distilling off a mixture of diol and diethyl carbonate. Table 1 shows the results of analyzing the obtained polycarbonate diol. This polycarbonate diol is abbreviated as PC-1.

Embodiment 2

[0101] The reaction was carried out using the apparatus shown in Example 1. 760 g (8.6 mol) of ethylene carbonate, 210 g (2.3 mol) of 1,4-butanediol, 550 g (5.3 mol) of 1,5-pentanediol, and 115 g (1.0 mol) of 1,6-hexanediol were added. Furthermore, 0.5 g of titanium tetrabutoxide was added as a catalyst, and it stirred and heated under normal pressure. Next, the reaction temperature was gradually raised from 150° C. to 190° C., and the reaction was carried out for 15 hours while distilling off a mixture of ethylene glycol and ethylene carbonate generated. Thereafter, the pressure was reduced to 14 kPa, and the reaction was further performed at 190° C. for 8 hours while distilling off diol and ethylene carbonate. Table 1 shows the analysis results of the obtained polycarbonate diol. The polycarbonate diol is abbreviated as PC-2.

Embodiment 3

[0103] Add 740g (8.4mol) of ethylene carbonate, 170g (1.9mol) of 1,4-butanediol, 390g (3.8mol) of 1,5-pentanediol and 330g (2.8mol) of 1,6-hexanediol, In addition, the reaction was performed under the conditions shown in Example 2 using the apparatus of Example 1. Table 1 shows the analysis results of the obtained polycarbonate diol. The polycarbonate diol is abbreviated as PC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com