A hydraulically driven spray device

A technology of injection device and hydraulic drive, which is used in muffler devices, exhaust devices, engine components, etc., can solve the problems of high machining accuracy, high cost, complex structure, etc., achieve high accuracy, facilitate deburring, and ensure response. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

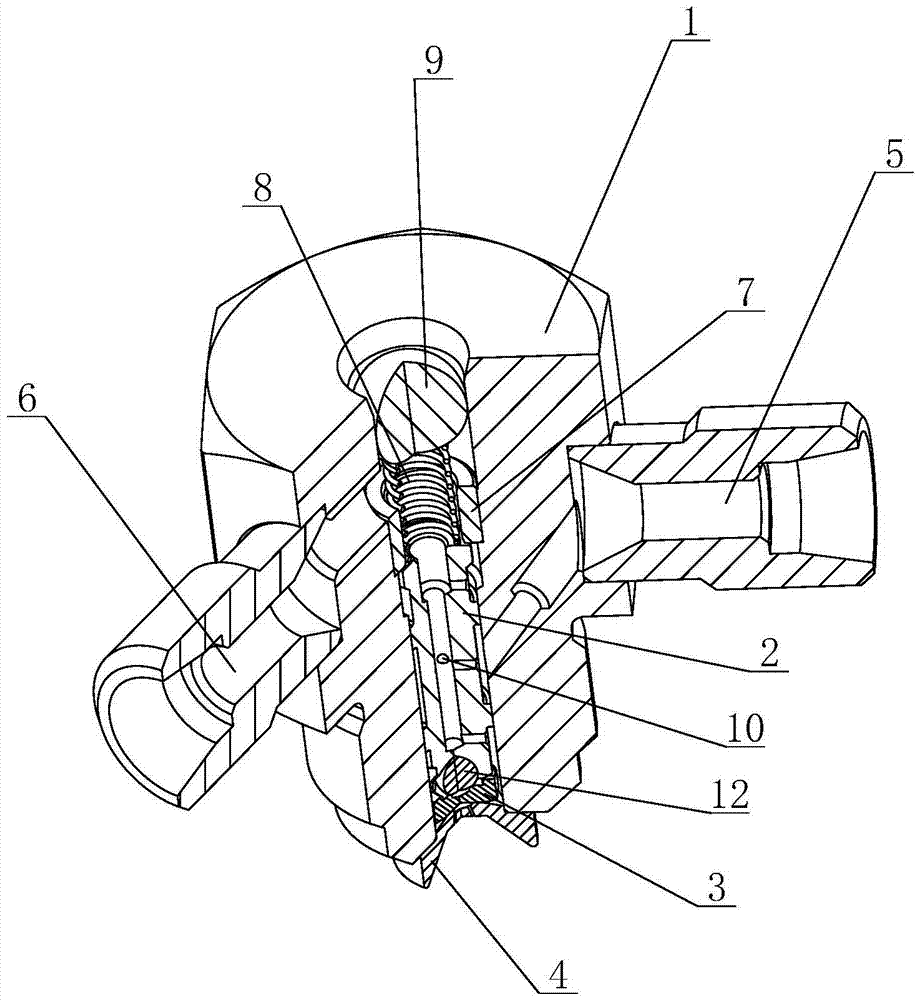

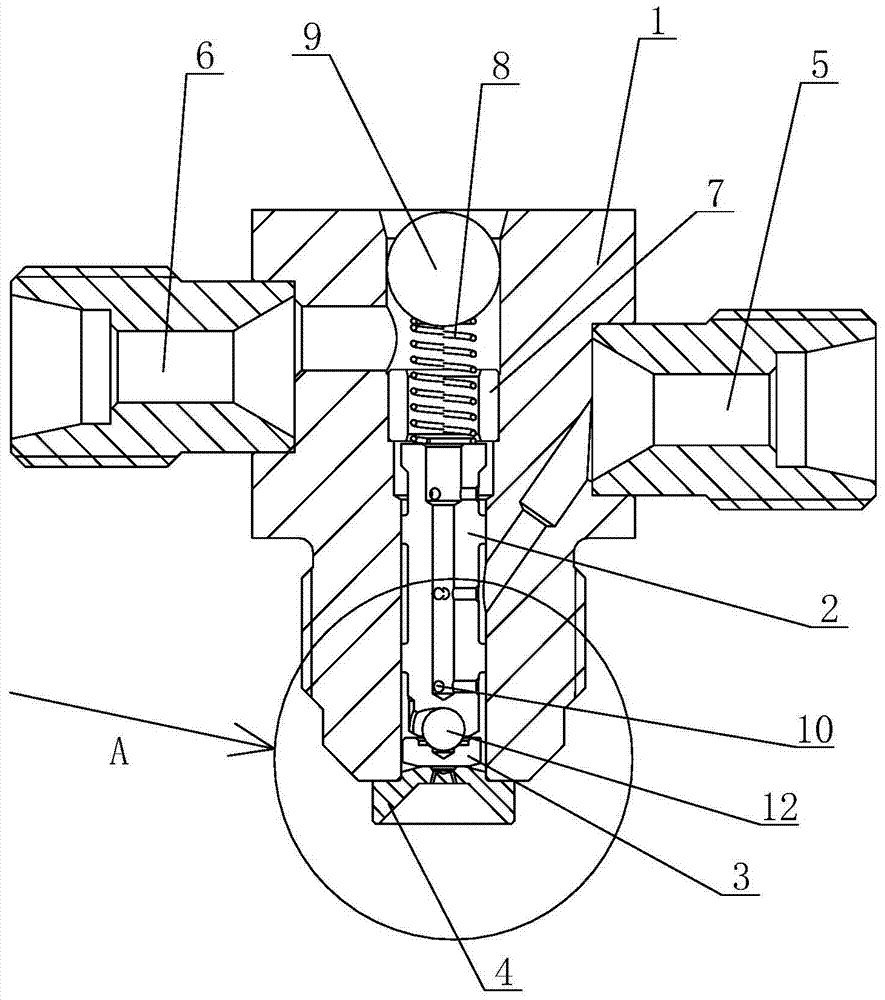

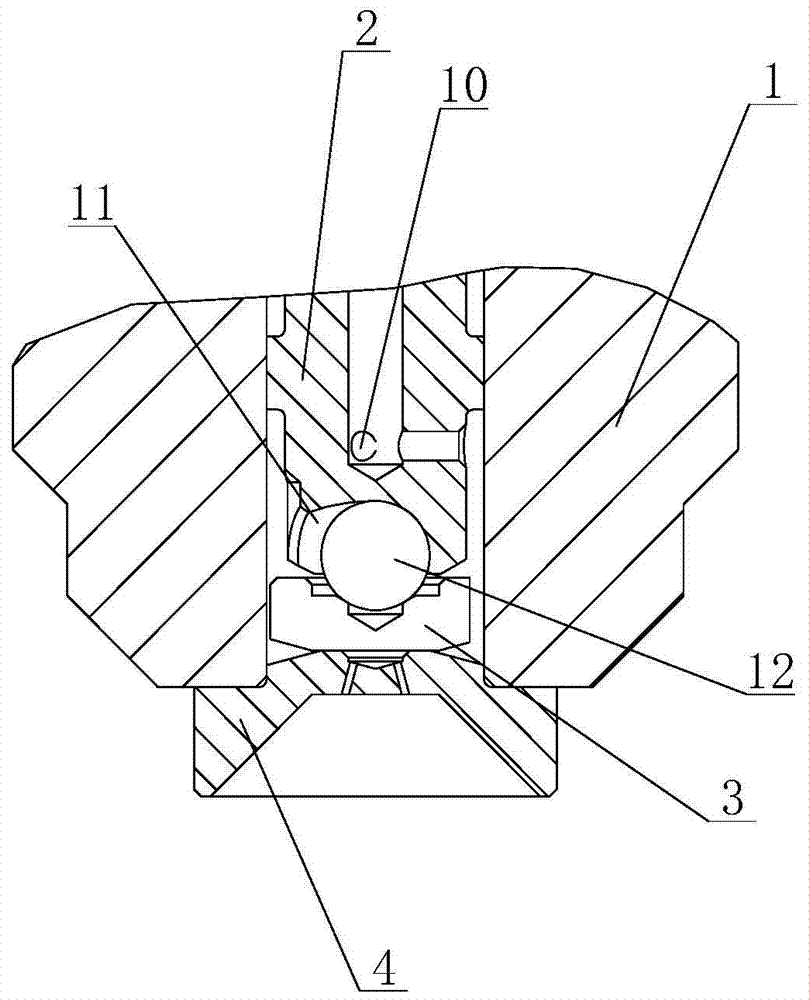

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0020] see Figure 1 to Figure 3 As shown, in this embodiment, a hydraulically driven injection device includes a valve body 1, a valve stem 2, a valve core 3, a valve seat 4, a liquid inlet 5, a liquid outlet 6, a limit sleeve 7, and a spring 8 And adjusting steel ball 9, the valve seat 4 is set on the bottom of the valve body 1 and has a spray hole on it, the valve body 1 is provided with a liquid inlet 5 and a liquid outlet 6, and the valve The body 1 is provided with an accommodating cavity for the lead, and the accommodating cavity is provided with an adjusting steel ball 9, a spring 8, a limit sleeve 7, a valve stem 2 and a valve core 3 sequentially from top to bottom. The position sleeve 7 is used to constrain the stroke of the valve stem 2 and is set on the top of the valve stem 2, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com