Method for processing exhaust gas containing high-concentration organic pollutant

An organic pollutant, high-concentration technology, used in combustion methods, combustion types, incinerators, etc., can solve problems such as inapplicable waste gas, achieve the effect of small footprint, make up for technical limitations, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

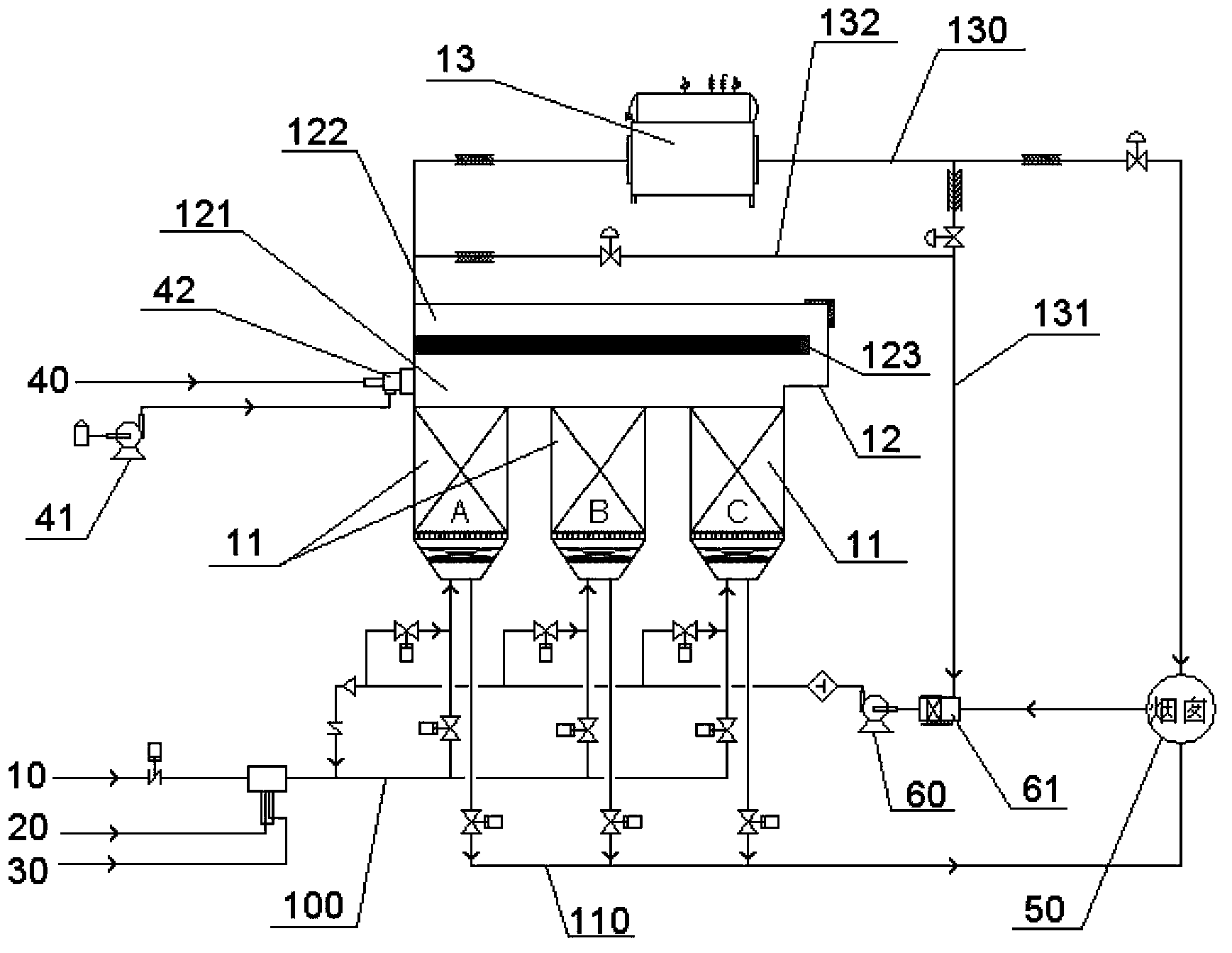

[0054] The exhaust gas 10 to be treated, the ammonia gas 20 and the air 30 are all connected to the exhaust gas delivery pipeline 100 and sent to the first heat accumulator 11A.

[0055] The first regenerator 11A is heated to 850-900°C in advance, and the ceramic bed that has accumulated heat in the first regenerator 11A preheats the passing gas (the ceramic regenerator bed is cooled), and the preheated exhaust gas is sent to into the first chamber 121 of the combustion chamber 12.

[0056] At the same time, the auxiliary fuel is sent into the first chamber 121 through the auxiliary fuel inlet 42 on the left side, and the combustion-supporting fan 41 blows oxygen or air into the first chamber 42 to assist combustion. The gas enters the second chamber 122 through the right end of the first chamber 121 to continue combustion. Fully react under high temperature conditions in the combustion chamber 12, and release a large amount of heat, so that the temperature of the combustion ...

Embodiment 2

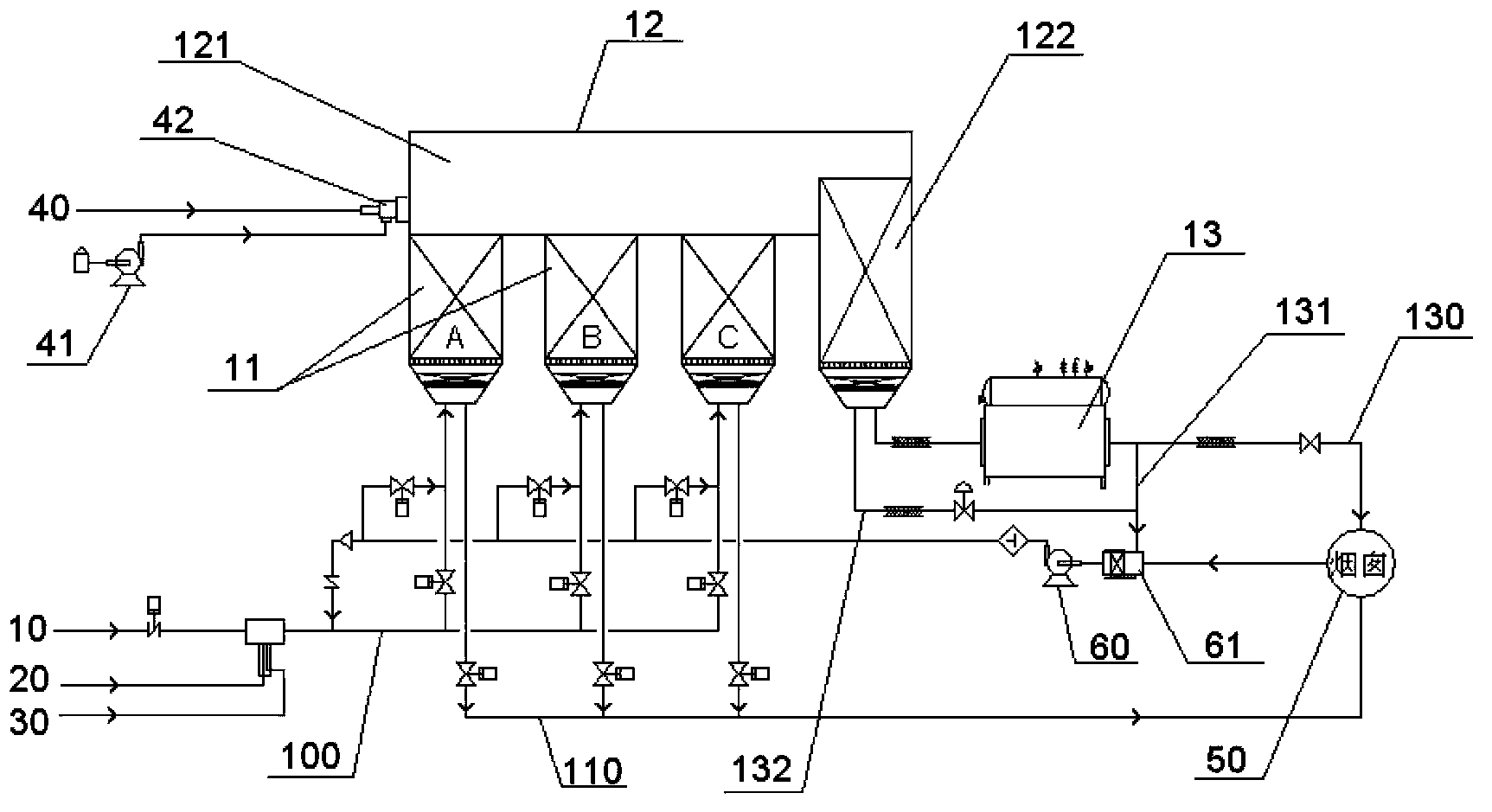

[0064] refer to image 3 Referring to Embodiment 1, in this embodiment, the combustion chamber 12 includes a first chamber 121 and a second chamber 122, and the second chamber 122 itself is an independent heat storage chamber. The combusted waste gas is conveyed through the bottom of the second chamber into two gas discharge pipes, one of which is a gas discharge pipe 130, and the gas discharge pipe 130 passes through the preheat recovery system 13 to absorb the remaining heat, and a part of the waste gas is directly discharged into the chimney 60, the other part of the exhaust gas passes through the waste heat recovery system 13 and then passes through the branch pipe 131 and the mixer 61 to mix, and then enters the back blowing cleaning system through the back blower 60. Another gas discharge pipe (second branch pipe) 132 is mixed by the mixer 61 and then enters the back blowing cleaning system through the back blower 60 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com