Automatic calibration device and automatic calibration method of laser module collimating lens

A technology of collimating lens and laser module, applied in the directions of installation, optics, optical components, etc., can solve the problems of hidden safety hazards, long working hours, unavoidable human errors, etc., to improve the yield and efficiency, shorten the manufacturing cycle, and avoid artificial Effects of Calibration Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

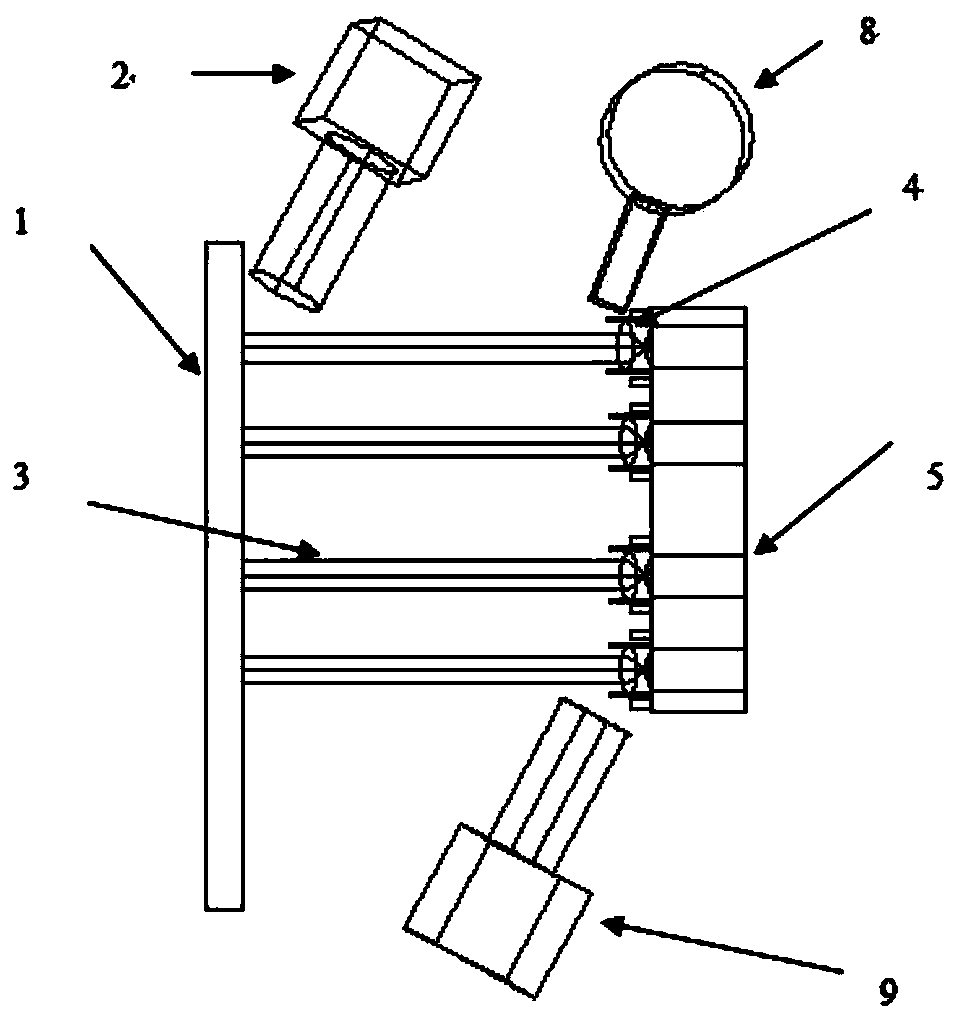

[0020] like figure 1 As shown, an automatic calibration device for a laser module collimator lens, including a spot calibration plate 1, a first CCD image alignment system 2, a collimator lens 4, a laser module 5, a robot arm 8, and a second CCD image alignment system 9 and dispensing system (not shown in the figure). The light spot calibration plate 1 is an aluminum plate, on which the light spot calibration position is marked as the calibration mark point 7 . The laser module 5 is used to emit the laser beam 3 , and the front end of the laser module 5 is opposite to the side of the spot calibration plate 1 provided with the calibration mark point 7 . The laser module 5 includes a laser and a deck for fixing the laser, and the deck is distributed in an equidistant matrix. The laser is evenly distributed after being fixed on the deck, which helps the laser to emit light evenly and has a better heat dissipation effect. The robot arm 8 is used to move and position the collima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com