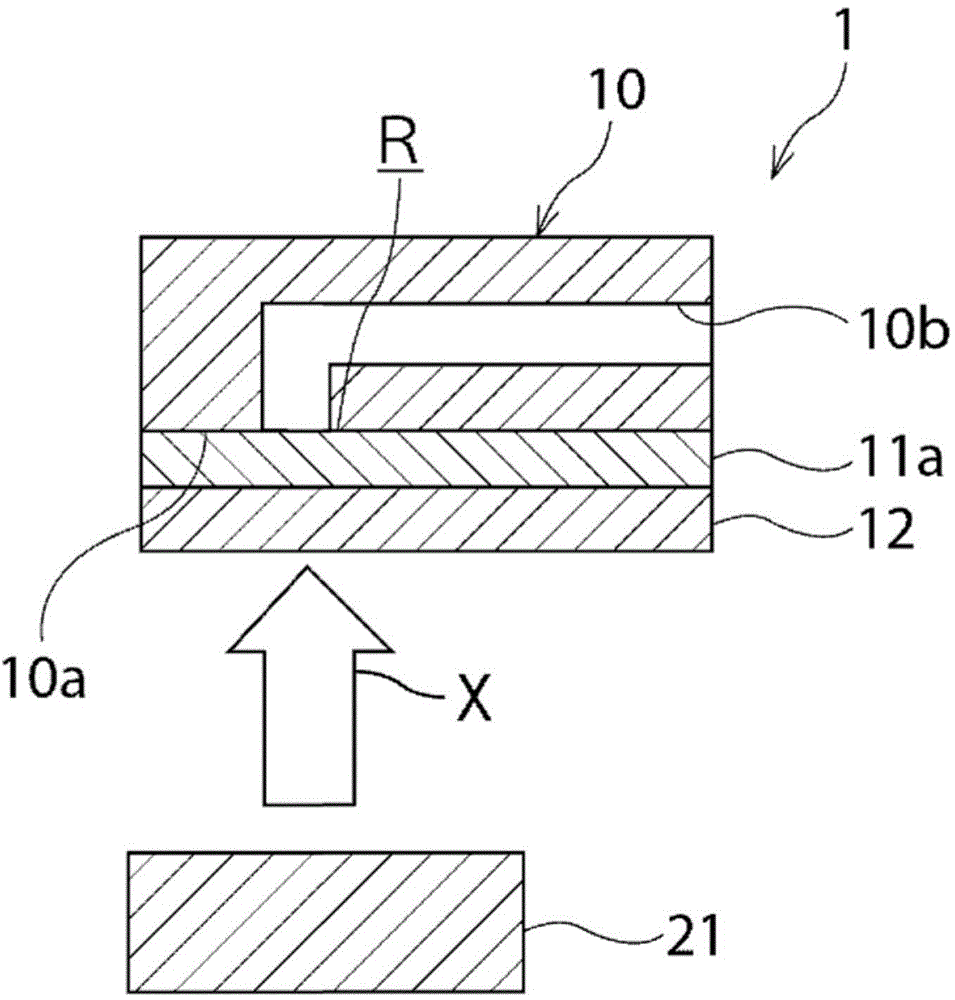

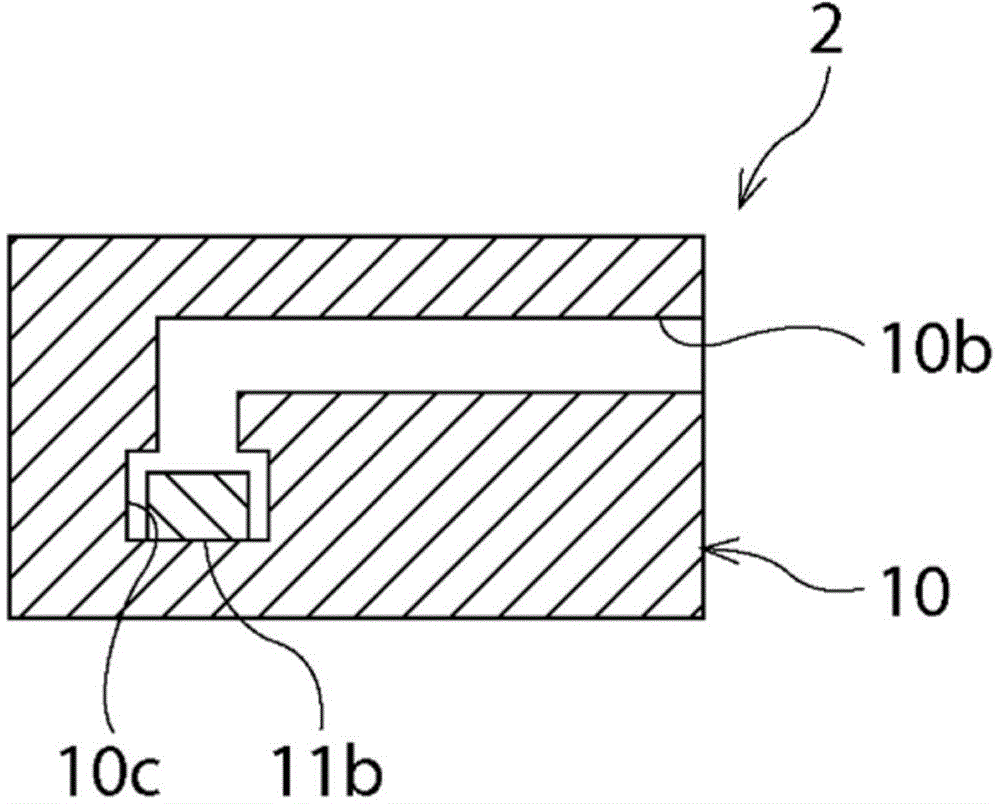

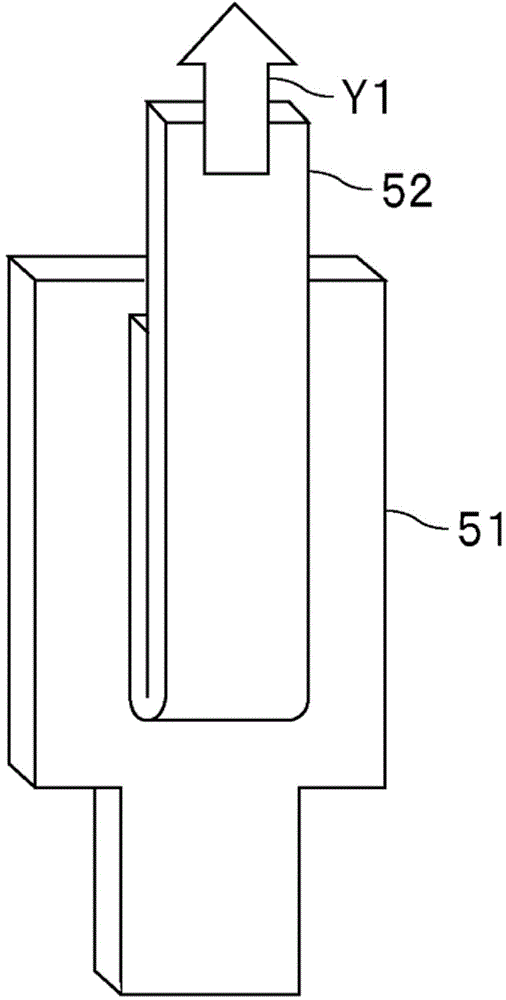

Gas-generating material and micropump

A technology of gas generation and gas generating agent, which is applied to the generation of compressed gas, gas collection devices, pumps, etc., to achieve the effect of improving adhesion and increasing the amount of gas generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0223] The following were mixed to obtain a mixture: 97 parts by mass of n-butyl acrylate (manufactured by Nippon Catalyst Co., Ltd.), 3 parts by mass of acrylic acid (manufactured by Nippon Catalyst Co., Ltd.), 0.05 parts by mass of Irgacure 907 (manufactured by Nagase Sangyo Co., Ltd.), and ethyl acetate 200 parts by mass. Next, ultraviolet rays were irradiated to this mixture for 4 hours, and the adhesive resin A (acrylic adhesive A) which is an acrylic copolymer was produced. The weight average molecular weight of binder resin A was about 700,000. The obtained binder resin A has an SP value in the range of 7 to 10.5.

Embodiment 1

[0225] 100 parts by mass of the binder resin A and 567 parts by weight of ethyl acetate as a solvent were mixed. The following were mixed and processed into a film: 100 parts by mass of binder resin A (wherein, 567 parts by mass of ethyl acetate as a solvent was blended together with binder resin A), 110 parts by mass of GAP4006 (glycidyl azide polymer, manufactured by NOF Corporation), N-2-(aminoethyl)-3-aminopropylmethyldimethoxysilane as a silane coupling agent having an amino group (KBM-602 manufactured by Shin-Etsu Chemical Co., Ltd.) 0.001 parts by mass, 2 parts by mass of tripropylamine (tri-n-propylamine) as a tertiary amine, 2-isopropylthioxanthone (DKSH Japan Co., Ltd.) as a photosensitizer IPX) 3.5 parts by mass, and N,N,N',N'-tetraglycidyl-1,3-benzenedi(methanamine) as a crosslinking agent (E-AX toluene manufactured by Soken Chemical Co., Ltd. 5% liquid) 0.5 parts by mass. The film was heated at 110° C. for 5 minutes to remove ethyl acetate as a solvent. This wa...

Embodiment 2~14 and comparative example 1~6

[0229] As shown in the following Tables 1 and 2, except that the types and amounts (units are parts by mass) of the compounding components were changed, a gas generating material was obtained and a micropump was produced in the same manner as in Example 1. In addition, in Examples 2-14, the silane coupling agent which has an amino group was used. In Comparative Examples 1, 2, 4, and 6, a silane coupling agent not having an amino group was used. In Comparative Examples 3 and 6, no silane coupling agent was used.

[0230] In addition, the kind of the silane coupling agent used is as follows.

[0231] N-2-(aminoethyl)-3-aminopropylmethyldimethoxysilane (KBM-602 manufactured by Shin-Etsu Chemical Co., Ltd.)

[0232] N,N-bis[(3-trimethoxysilyl)propyl]ethylenediamine (manufactured by Gelest)

[0233] 3-Aminopropyltrimethoxysilane (KBM-903 manufactured by Shin-Etsu Chemical Co., Ltd.)

[0234] 3-Aminopropyltriethoxysilane (KBE-903 manufactured by Shin-Etsu Chemical Co., Ltd.)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com