Rotary anode and method for producing same

A technology of rotating anodes and substrates, applied in the directions of X-ray tube electrodes, X-ray tube targets and converters, X-ray tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

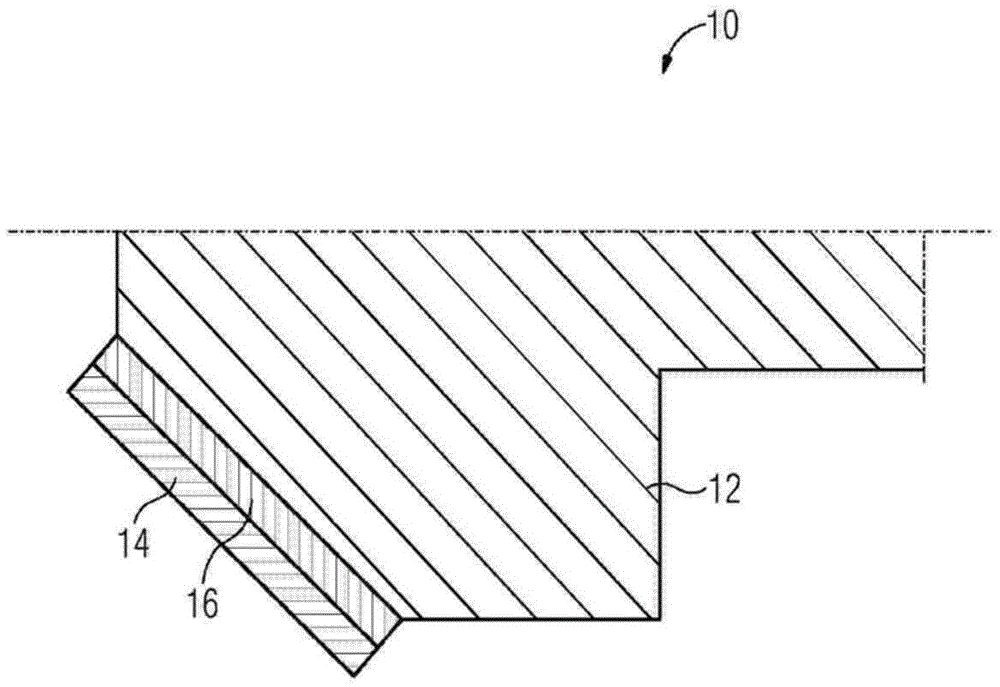

[0021] The rotary anode for an X-ray tube, designated in its entirety by 10 and only partially shown in the figures, comprises a base body 12 made of ceramic and a combustion zone 14 made of tungsten, which emits X-rays when irradiated by electrons radiation.

[0022] Due to the higher energy density in the operation of new X-ray tubes, the substrate 12 requires a material that is both resistant to high temperatures and has a sufficiently high mechanical strength at high temperatures so that a rotational frequency of 300 to 400 Hz can be maintained. A suitable class of materials satisfying these conditions are ceramics composed of silicon carbide or silicon carbide / diboride composites.

[0023] In order to improve the fixation of the combustion zone 14 on the base body made of this material, an intermediate layer 16 is formed between the combustion zone 14 and the base body 12 during the production of the rotary anode 10 , which intermediate layer 16 is made of high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com