Quick enzyme inactivation method

A blunt enzyme, fast technology, applied in food science, food preservation, preservation of fruits/vegetables through radiation/electrical treatment, etc., can solve the problems of unsatisfactory effect of blunt enzymes, insufficient time for inactivating enzymes, etc., and achieve easy to overcome The effect of changing the color of the material, improving the strengthening effect, and effectively inactivating the enzyme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

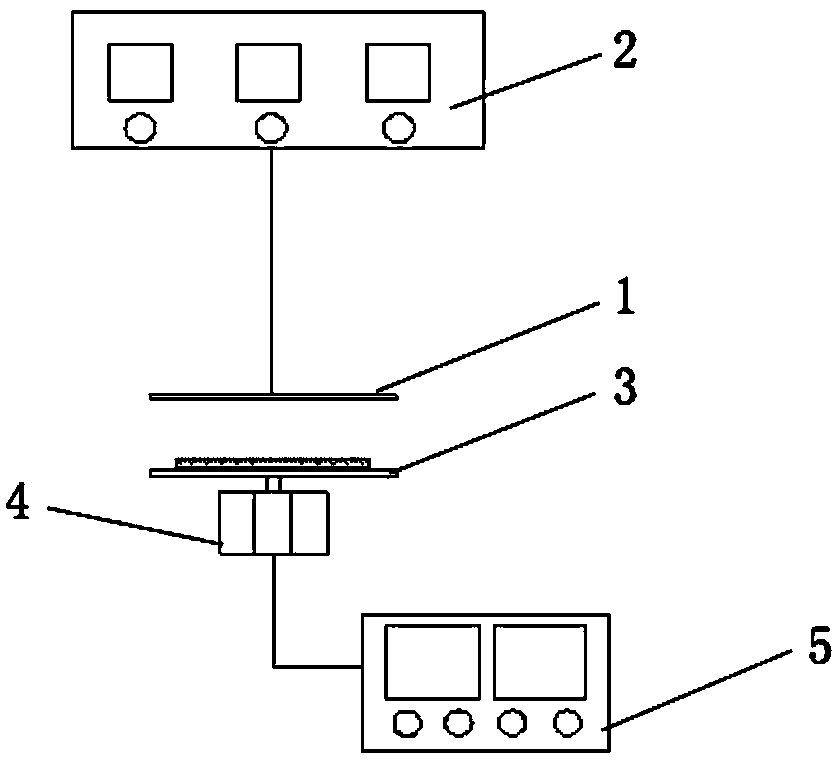

Image

Examples

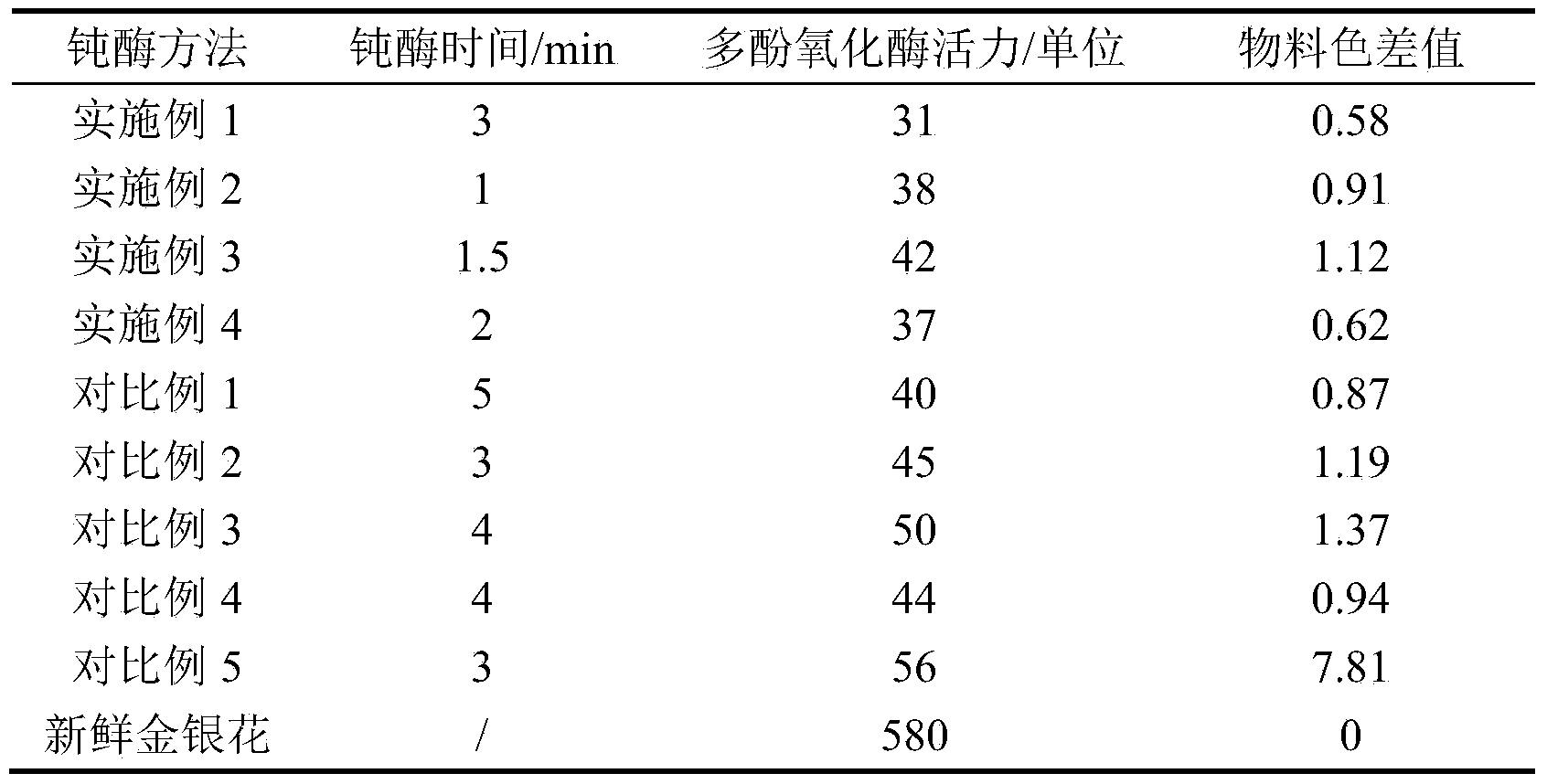

Embodiment 1

[0021] Honeysuckle is rich in polyphenol oxidase and phenolic substances, which are prone to enzymatic browning during storage, resulting in a large loss of active ingredients and serious browning of product color. Therefore, it is necessary to effectively inactivate the polyphenol oxidase in honeysuckle before processing. The commonly used inactivation method is steam inactivation. Although the steam inactivation enzyme can realize the inactivation of the enzyme activity within a few minutes, it is easy to cause severe shrinkage of the honeysuckle, and its color also changes from the green of the fresh material to an abnormal green. At present, farmers often use drying rooms to dry honeysuckle, and use sulfur dioxide produced by burning coal to protect the color of honeysuckle, but sulfur is easy to remain in honeysuckle, resulting in excessive sulfur. The use of chemical reagents to inhibit enzyme activity will easily cause changes in the physiological activity of honeysuckl...

Embodiment 2

[0028] The fast blunt enzyme method of honeysuckle in the present embodiment, comprises the following steps:

[0029] (1) Select fresh honeysuckle, which is green in color and plump in appearance, and laid flat on a mesh material tray for standby, with a material layer thickness of 4mm;

[0030] (2) Turn on the far-infrared radiation, the radiation power is 1000W, and the peak wavelength is 5 μm. After reaching the working parameters, quickly place the mesh material tray filled with fresh honeysuckle on the ultrasonic radiation plate, and adjust the distance between the far-infrared radiation plate and the fresh honeysuckle. The distance between them is 5cm, the ultrasonic wave is turned on, the ultrasonic power is set to 800W, the frequency is 20kHz, and the inactivated enzyme is treated for 1min.

Embodiment 3

[0032] The fast blunt enzyme method of honeysuckle in the present embodiment, comprises the following steps:

[0033] (1) Select fresh honeysuckle, which is green in color and plump in appearance, and laid flat on a mesh material tray for standby, with a material layer thickness of 4mm;

[0034] (2) Turn on the far-infrared radiation, the radiation power is 1000W, and the peak wavelength is 5 μm. After reaching the working parameters, quickly place the mesh material tray filled with fresh honeysuckle on the ultrasonic radiation plate, and adjust the distance between the far-infrared radiation plate and the fresh honeysuckle. The distance between them was 10cm, the ultrasonic wave was turned on, the ultrasonic power was set to 400W, the frequency was 100kHz, and the blunt enzyme was treated for 1.5min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peak wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com