Hollow heat-insulating and wear-resistant hydrophobic glass

A hydrophobic glass, hollow technology, applied in parallel glass structures, glass/slag layered products, building components, etc., can solve the problems of poor wear resistance of hydrophobic films, reduced hydrophobic properties of glass, and difficult coating of hydrophobic films, etc. Cool, keep hydrophobic performance, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

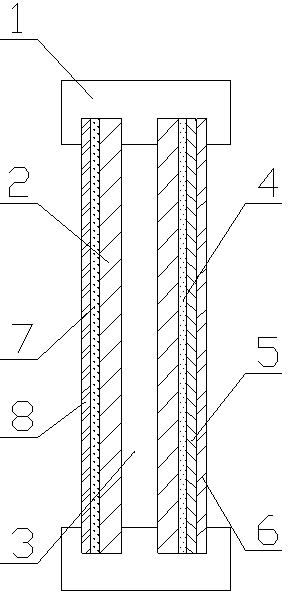

[0020] see figure 1 , a kind of hollow heat-insulating wear-resistant hydrophobic glass of the present invention, it comprises frame 1, and described frame 1 is provided with two inner and outer flat glasses 2 in parallel, and described frame 1 and inner and outer two flat glasses 2 form hollow cavity 3, The hollow cavity 3 is evacuated or filled with an inert gas, the outer surface of the outer plate glass 2 is provided with a resin layer 4, and the surface of the resin layer 4 is provided with a micro-nano structure layer 5, and the micro-nano structure layer 5 is The surface is provided with a hydrophobic modification layer 6, the resin layer 4 adopts epoxy resin, unsaturated resin or phenolic resin, the micro-nano structure layer 5 adopts a silicon dioxide micro-nano layer structure layer, and the hydrophobic modification layer 6 It is made of trimethylchlorosilane, heptadecylfluorodecyltrimethoxysilane, perfluoroalkylchlorosilane or perfluoroalkylalkoxysilane, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com