Double-layer solar cell module packaging adhesive film and preparation method thereof

A technology for solar cells and encapsulation films, applied in electrical components, chemical instruments and methods, circuits, etc., to achieve the effects of preventing component PID, superior bonding performance, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A double-layer solar cell module encapsulation adhesive film is composed of an EVA adhesive film outer layer and an EVA adhesive film inner layer;

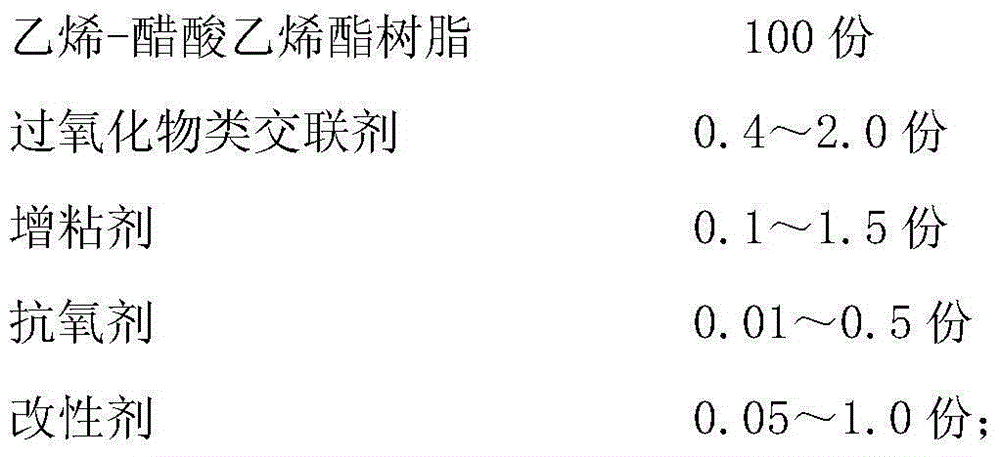

[0039] The outer layer of the EVA film comprises the following raw materials in parts by weight:

[0040]

[0041] The inner layer of the EVA film comprises the following raw materials in parts by weight:

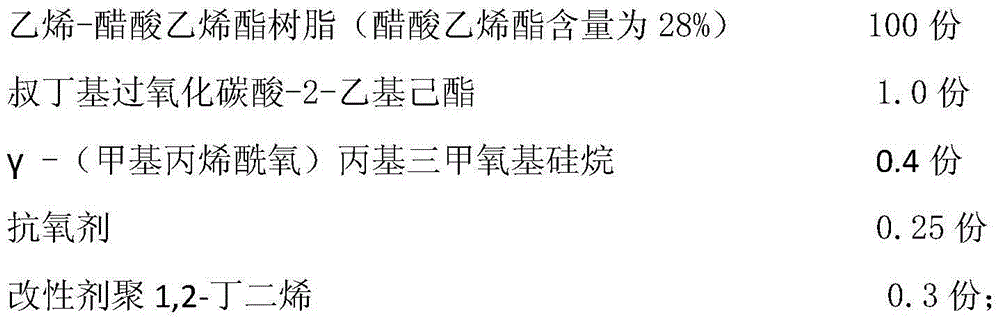

[0042] Ethylene-vinyl acetate resin (28% vinyl acetate content) 100 parts

[0043] 1.0 parts of tert-butyl peroxycarbonate-2-ethylhexyl.

[0044] The ethylene-vinyl acetate resin is produced by Singapore TPC Company, trade name: KA-40; the modifier poly-1,2-butadiene is produced by Jihua Company, trade name: JH1300 (number average molecular weight 1300) ; The antioxidant consists of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and three (2,4-di-tert-butylphenyl) phosphite Mixed according to the mass ratio of 1:1.

[0045] The preparation method of the above-mentioned double-layer solar cell module ...

Embodiment 2

[0049] A double-layer solar cell module encapsulation adhesive film is formed by compounding the outer layer of the EVA adhesive film and the inner layer of the EVA adhesive film;

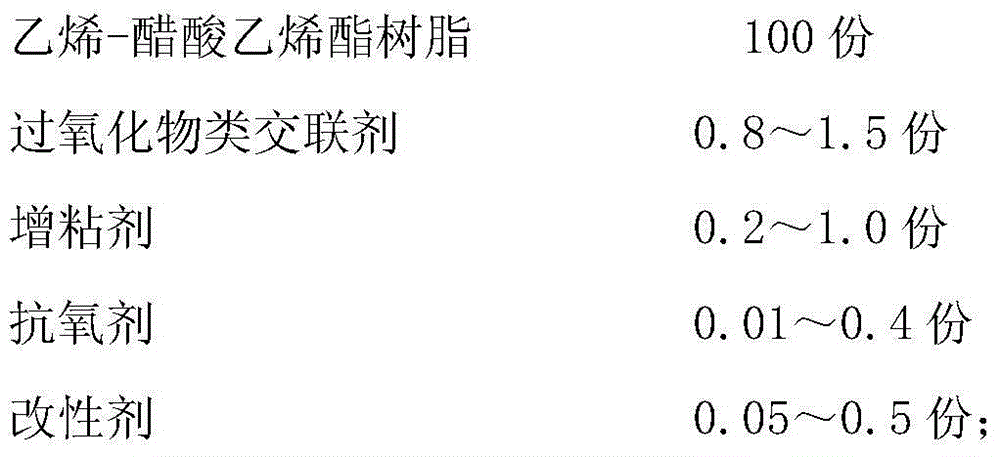

[0050] The outer layer of the EVA film comprises the following raw materials in parts by weight:

[0051]

[0052] The inner layer of the EVA film comprises the following raw materials in parts by weight:

[0053] Ethylene-vinyl acetate resin (28% vinyl acetate content) 100 parts

[0054]1.0 parts of tert-butyl peroxycarbonate-2-ethylhexyl.

[0055] The ethylene-vinyl acetate resin is produced by Singapore TPC Company, trade name: KA-40; the modifier poly-1,2-butadiene is produced by Jihua Company, trade name: JH1300 (number average molecular weight 1300) ; The antioxidant consists of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and three (2,4-di-tert-butylphenyl) phosphite Mixed according to the mass ratio of 1:1.

[0056] The preparation method of the above-mentioned double...

Embodiment 3

[0060] A double-layer solar cell module encapsulation adhesive film is composed of an EVA adhesive film outer layer and an EVA adhesive film inner layer;

[0061] The outer layer of the EVA film comprises the following raw materials in parts by weight:

[0062]

[0063] The inner layer of the EVA film comprises the following raw materials in parts by weight:

[0064] Ethylene-vinyl acetate resin (28% vinyl acetate content) 100 parts

[0065] 1.1 parts of tert-butylperoxycarbonate-2-ethylhexyl ester.

[0066] The ethylene-vinyl acetate resin is produced by Singapore TPC Company, trade name: KA-40; the modifier polyisoprene is produced by Puyang Linshi New Chemical Materials Co., Ltd., trade name: IR-550 ( Number average molecular weight 4700); The antioxidant is composed of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and three (2,4-di-tert-butylbenzene base) phosphite mixed at a mass ratio of 1:1.

[0067] The preparation method of the above-mentioned do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com