Glass fiber product and glass fiber reinforced plastic

A glass fiber and product technology, applied in the field of glass fiber reinforced plastics, can solve the problems of unintended use, reduced bonding performance, and inability of sizing agent to penetrate deeply, and achieve less white glass, high strength, and excellent bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

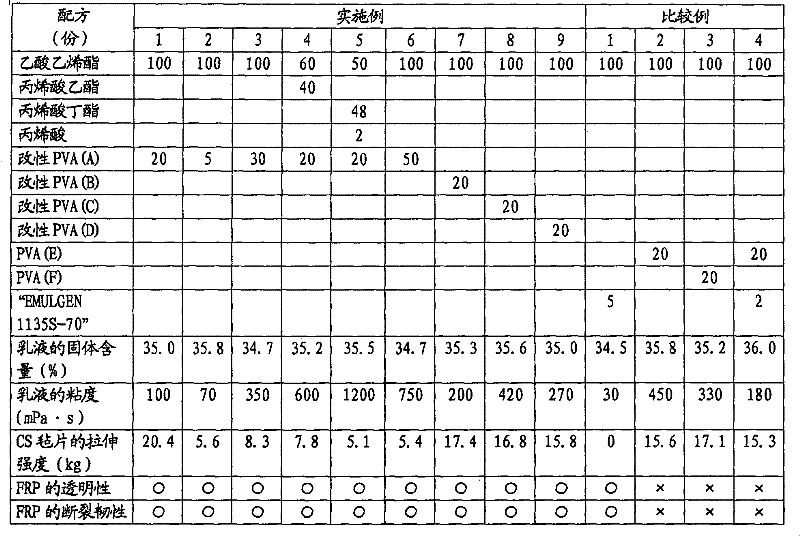

Embodiment 1

[0065] (preparation of emulsion)

[0066] A 3 liter glass vessel equipped with a stirrer, reflux condenser and thermometer was provided. Deionized water (173 parts) and ethylene-modified PVA (A) (ethylene content 7%, degree of saponification: 98.5 mol%, average degree of polymerization: 400; 20 parts) were placed in a container made of glass. After the air was completely purged with nitrogen, stirring was started.

[0067] The internal temperature of the glass container was increased to 80°C, at which temperature vinyl acetate monomer (100 parts), 10% aqueous hydrogen peroxide (1 part) and 10% tartaric acid aqueous solution (1.5 parts) were all continuously Add for 4 hours. Then, the reaction was performed at 80°C for 1 hour, followed by cooling to 30°C.

[0068] A vinyl acetate polymer emulsion having an evaporation residue (solid content) of 35.0% and a viscosity of 100 mPa·s was obtained. The methods of measuring the evaporation residue and viscosity will be described b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com