Improved glue and PET base material co-granulation type protective film and manufacturing method thereof

A production method and improved technology, applied in the direction of adhesives, adhesive types, pressure-sensitive films/sheets, etc., can solve the problem of harsh storage and transportation conditions, high organic solvent prices, and difficult recycling of protective films/adhesive tapes, etc. The problem is to achieve a win-win situation of economic and social environmental benefits, the preparation method is simple and feasible, and the effect of resisting the influence of environmental humidity is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

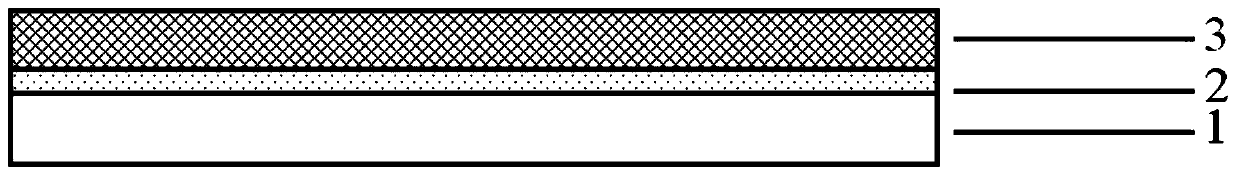

[0089] A method for making a protective film that can be co-granulated with improved glue and PET substrate:

[0090] A. Chemical synthesis of improved saturated polyester pressure-sensitive adhesives treated with solubilization and grafting:

[0091] 1. Polymerization of compatibilizer:

[0092] 1) Mix accurately measured 90Kg of caprolactone monomer, 3.0Kg of acrylic acid, 3.0Kg of hydroxyethyl acrylate and 60Kg of xylene in the reaction kettle and heat up to 140°C-150°C to stabilize the reflux for 10 minutes above;

[0093] 2) Dissolve 0.50Kg stannous octoate with 10Kg xylene and add it dropwise to the reaction kettle within 10 minutes; the preparation container and dropping tank of stannous octoate are rinsed twice with 10Kg xylene respectively, and the flushing solution is collected in In the reactor;

[0094] 3) Continue to keep the temperature at 140°C-150°C to stabilize the reflux for more than 15 minutes;

[0095] 4) The polymerization time is not less than 240 mi...

Embodiment 2

[0124] A method for making a protective film that can be co-granulated with improved glue and PET substrate:

[0125]A. Preparation of improved saturated polyester pressure-sensitive adhesive coating solution for solubilization and grafting:

[0126] 1) 6Kg Cymel303 type methyl etherified melamine resin was stirred and dissolved with 10Kg of ethyl acetate to obtain a crosslinking agent dilution;

[0127] 2) Slowly add 40Kg of the solubilized and graft-modified modified saturated polyester pressure-sensitive adhesive into 24Kg of ethyl acetate under stirring, and continue stirring for more than 30 minutes to obtain the glue dilution;

[0128] 3) Add the crosslinking agent diluent and 700g of tributyl citrate to the glue diluent under stirring, and continue to stir for more than 30 minutes to obtain the improved saturated polyester pressure-sensitive adhesive with solubilization and grafting treatment. agent coating liquid;

[0129] B. Coating of modified saturated polyester p...

Embodiment 3

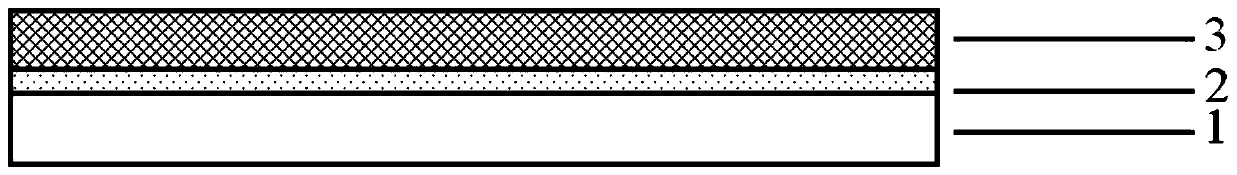

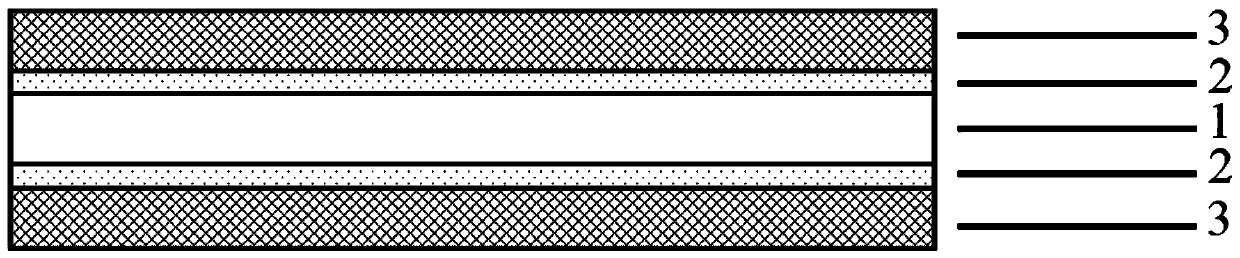

[0142] A method for making a double-sided protective film that can be co-granulated with improved glue and PET substrate:

[0143] A. Preparation of improved saturated polyester pressure-sensitive adhesive coating solution for solubilization and grafting:

[0144] 1) Stir and dissolve 10Kg of Cymel303 type methyl etherified melamine resin with 10Kg of ethyl acetate to obtain a crosslinking agent dilution;

[0145] 2) Slowly add 50Kg of the solubilized and grafted saturated polyester pressure-sensitive adhesive to 40Kg of ethyl acetate under stirring, and continue stirring for more than 30 minutes to obtain the glue dilution;

[0146] 3) Add the crosslinking agent diluent and 875g of tributyl citrate to the glue diluent under stirring, and continue to stir for more than 30 minutes to obtain the improved saturated polyester pressure-sensitive adhesive with solubilization and grafting treatment. agent coating liquid;

[0147] B. Coating of modified saturated polyester pressure-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com