A kind of low-temperature dehydrogenation magnesium-based composite material and its preparation method

A composite material and dehydrogenation technology, applied in the field of battery materials, can solve the problems of reduced thermal stability, no change in thermodynamic properties, weakened apparent activation energy, etc., to achieve improved low-temperature dehydrogenation performance, suitable thermal stability, and reduced The effect of thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a glove box filled with argon, the molar ratio of 2:1 MgH 2 -TiH 2 Mix, then add Pd with a mole fraction of 0.5% and mix thoroughly, put it into a ball mill tank with an on-off valve, pre-evacuate the ball mill tank, and then ball mill and mix on a planetary wheel ball mill with a ball-to-material ratio of 90:1 and a speed of 400rpm, ball milling time is 5 hours.

[0022] Among them, MgH 2 The purity is 95%, the particle size is 300 mesh; TiH 2 The purity is 99.5%, and the particle size is 200 mesh; the purity of Pd powder is 99.9%, and the particle size is 300 mesh.

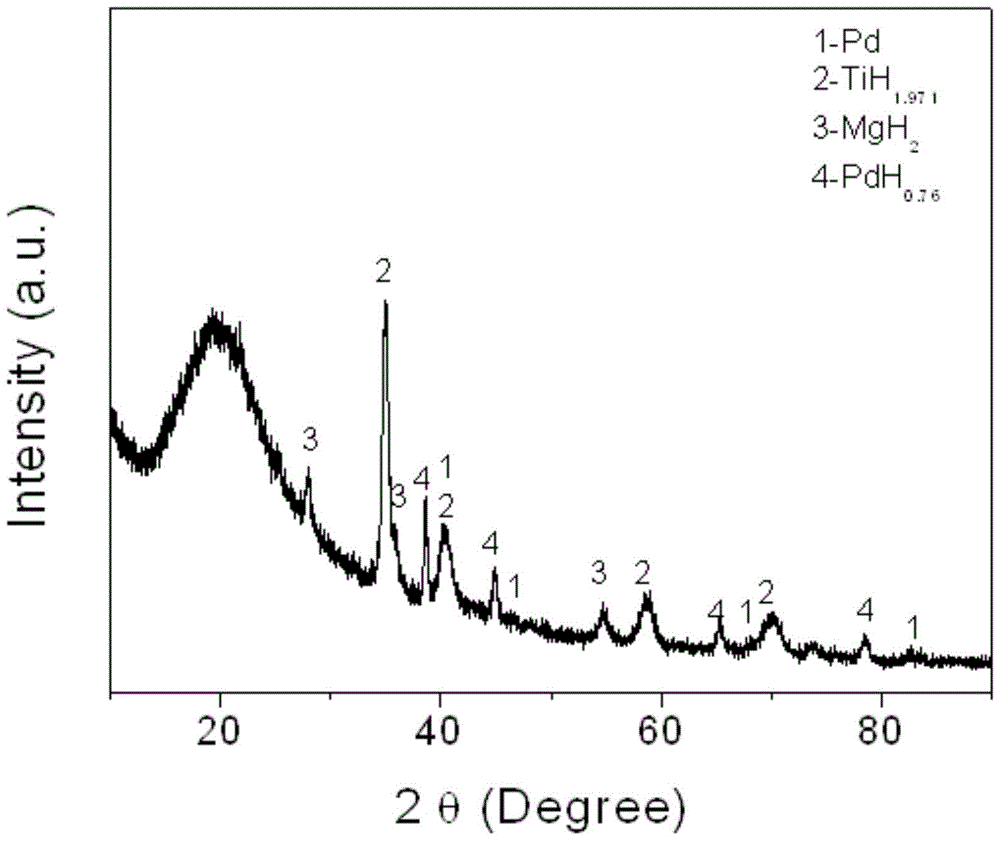

[0023] figure 1 for MgH 2 -TiH 2 - X-ray diffraction spectrum of Pd material mixed milled for 5 hours, showing that MgH 2 and TiH 2 For mechanical mixing, there is no reaction between the two during ball milling, and a small amount of Pd is hydrogenated to form PdH during ball milling. 2 .

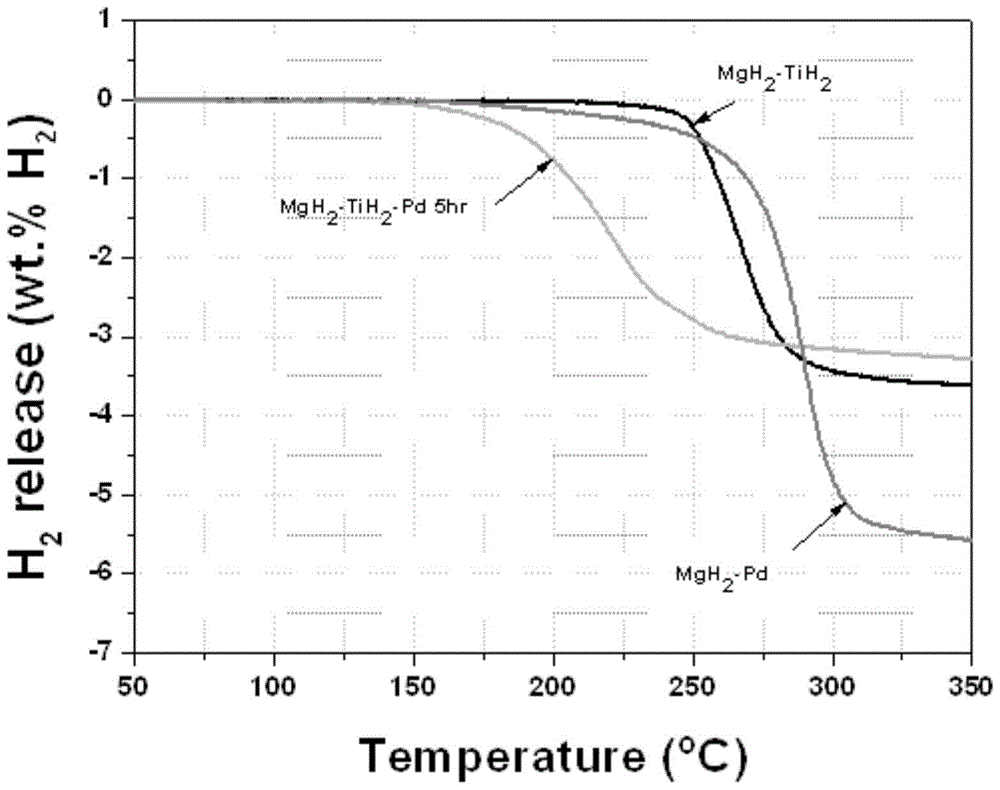

[0024] Test the hydrogen absorption and desorption performance of the sample: In a glove box filled wi...

Embodiment 2

[0027] In a glove box filled with argon, the molar ratio of 2:1 MgH 2 -TiH 2 Mix, then add Pd with a mole fraction of 3% and mix thoroughly, put it into a ball mill tank with a switch valve, pre-vacuumize the ball mill tank, and ball mill and mix on a planetary wheel ball mill, the ball-to-material ratio is 90:1, and the speed 400rpm, ball milling time is 10 hours.

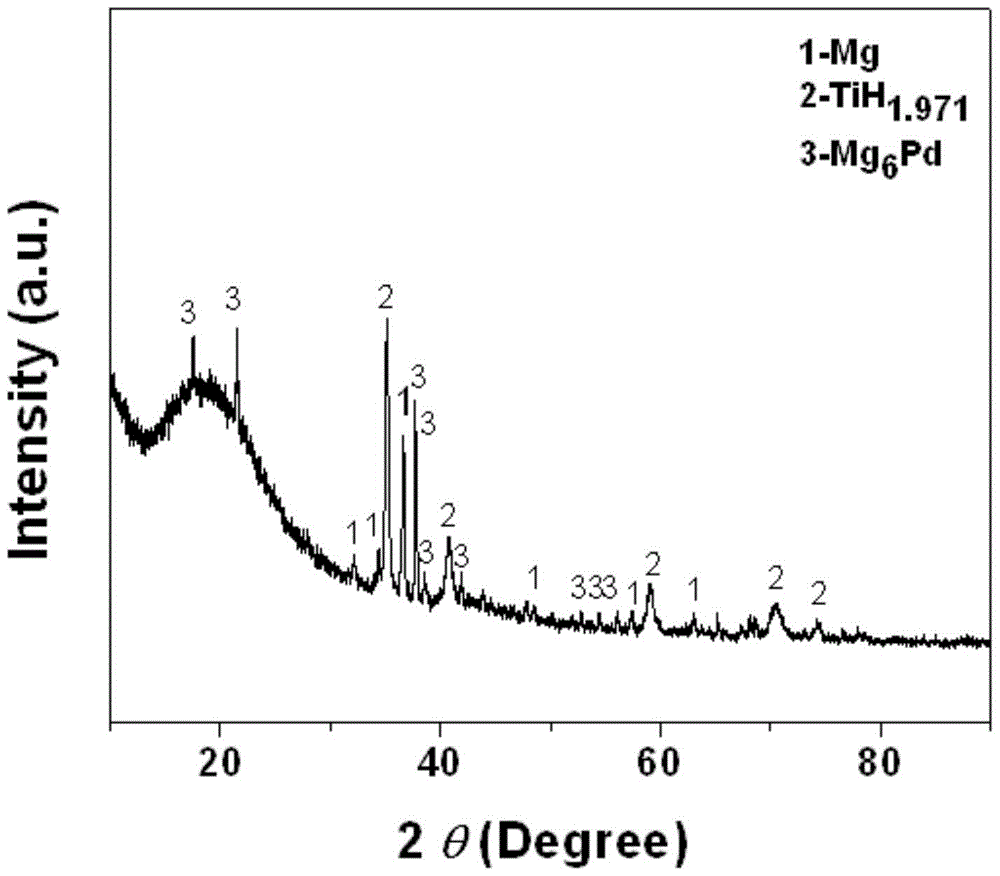

[0028] Figure 4 for MgH 2 -TiH 2 - X-ray diffraction spectrum of Pd material mixed milled for 10 hours, showing that MgH 2 and TiH 2 For mechanical mixing, there is no reaction between the two during ball milling, and a small amount of Pd is hydrogenated to form PdH during ball milling. 2 . Test the hydrogen absorption and desorption performance of the sample: In a glove box filled with argon, take out the sample prepared by the ball mill and weigh it, put it into a specific sample cell of the Sievert type gas-solid reaction test equipment, and seal it. Take out the sample cell and connect it tightly with...

Embodiment 3

[0030] In a glove box filled with argon, the molar ratio of 2:1 MgH 2 -TiH 2 Mix, then add Pd with a molar ratio of 3% and mix thoroughly, put it into a ball mill tank with a switch valve, pre-vacuumize the ball mill tank, and then ball mill and mix on a planetary wheel ball mill with a ball-to-material ratio of 80:1 and a speed of 300rpm, ball milling time is 15 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com